Hellwig Power Lift 6097 User Manual

Page 13

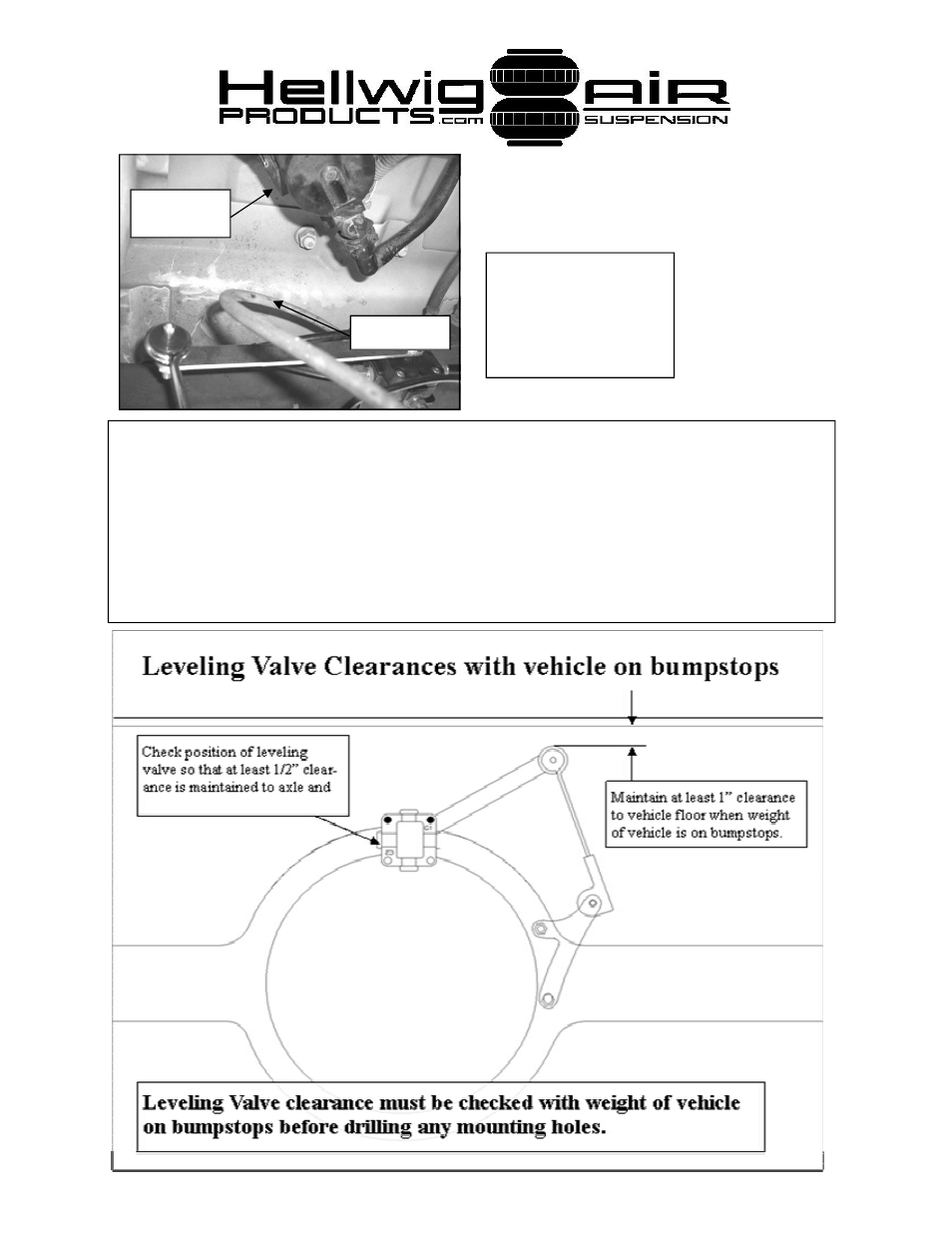

17. IMPORTANT– BEFORE DRILLING ANY MOUNTING HOLES IN CROSS-

MEMBER, remove jack stands and lower frame so that the weight of the vehicle is on

the bumpstops. CHECK POSITION OF LEVELING VALVE SO THAT IT CLEARS

AXLE ASSEMBLY AND BRAKE LINES. It will be a close fit but there should be at

least 1/2” of clearance. Relocate brake lines if required. Also check that the leveling

valve arm will not contact the floor of the vehicle or any other components—

evaporative canister, vent tube, exhaust pipe, etc. After verifying clearances proceed to

step 18—Do not drill holes at this time.

Evaporative

canister.

Vent Tube

IMPORTANT: Ensure lev-

eling valve and linkage will

not contact the floor, axle,

or evaporative canister

when full weight of vehicle

is on the bumpstops.

- Pro Series Silence (2 pages)

- Pro Series 61610 (2 pages)

- Pro Series 61901 (2 pages)

- Pro Series 61905 (2 pages)

- Pro Series Standard (2 pages)

- Load Pro Series LP 25 (2 pages)

- Load Pro Series LP 15 (1 page)

- Load Pro Series 9640 (1 page)

- Load Pro Series 9655 (2 pages)

- EZ 1000 (1 page)

- EZ 991 (1 page)

- Front Helper Spring 14114 (1 page)

- Front Helper Spring 14139 (2 pages)

- Helper Spring 820 (1 page)

- Helper Spring 979 (3 pages)

- Helper Spring 982 (2 pages)

- Helper Spring 1250 (1 page)

- Helper Spring 1251 (1 page)

- Helper Spring 1510 (2 pages)

- Helper Spring 1515 (1 page)

- Helper Spring 1520 (2 pages)

- Helper Spring 1555 (1 page)

- Helper Spring 1560 (1 page)

- Helper Spring 1565 (1 page)

- Helper Spring 1901 (3 pages)

- Helper Spring 1902 (2 pages)

- Helper Spring 1906 (1 page)

- Air 6005 (6 pages)

- Sway Bar 5909 (3 pages)

- Air 6006 (7 pages)

- Air 6012 (8 pages)

- Air 6014 (7 pages)

- Air 6016 (7 pages)

- Air 6090 (21 pages)

- Air 6091 (9 pages)

- Air 6102 (7 pages)

- Air 6106 (6 pages)

- Air 6108 (8 pages)

- Air 6107 (6 pages)

- Air 6110 (9 pages)

- Air 6111 (8 pages)

- Air 6118 (7 pages)

- Air 6150 (6 pages)

- Air 6154 (6 pages)

- Air 6210 (6 pages)