Hardware verification – Fluid Components International ST50 User Manual

Page 17

ST50 MASS FLOW

FLUID COMPONENTS INTERNATIONAL LLC

This page is subject to proprietary rights statement on last page

17

Doc. No. 06EN003367 Rev. D

Hardware Verification

Equipment Required:

Digital Multimeter

Screw Driver

The ST50 Flowmeter is comprised of 4 basic components:

1. Sensor element.

2. Customer interface circuit board

3. Control circuit assembly circuit board module.

4. Electronics enclosure.

Step 1

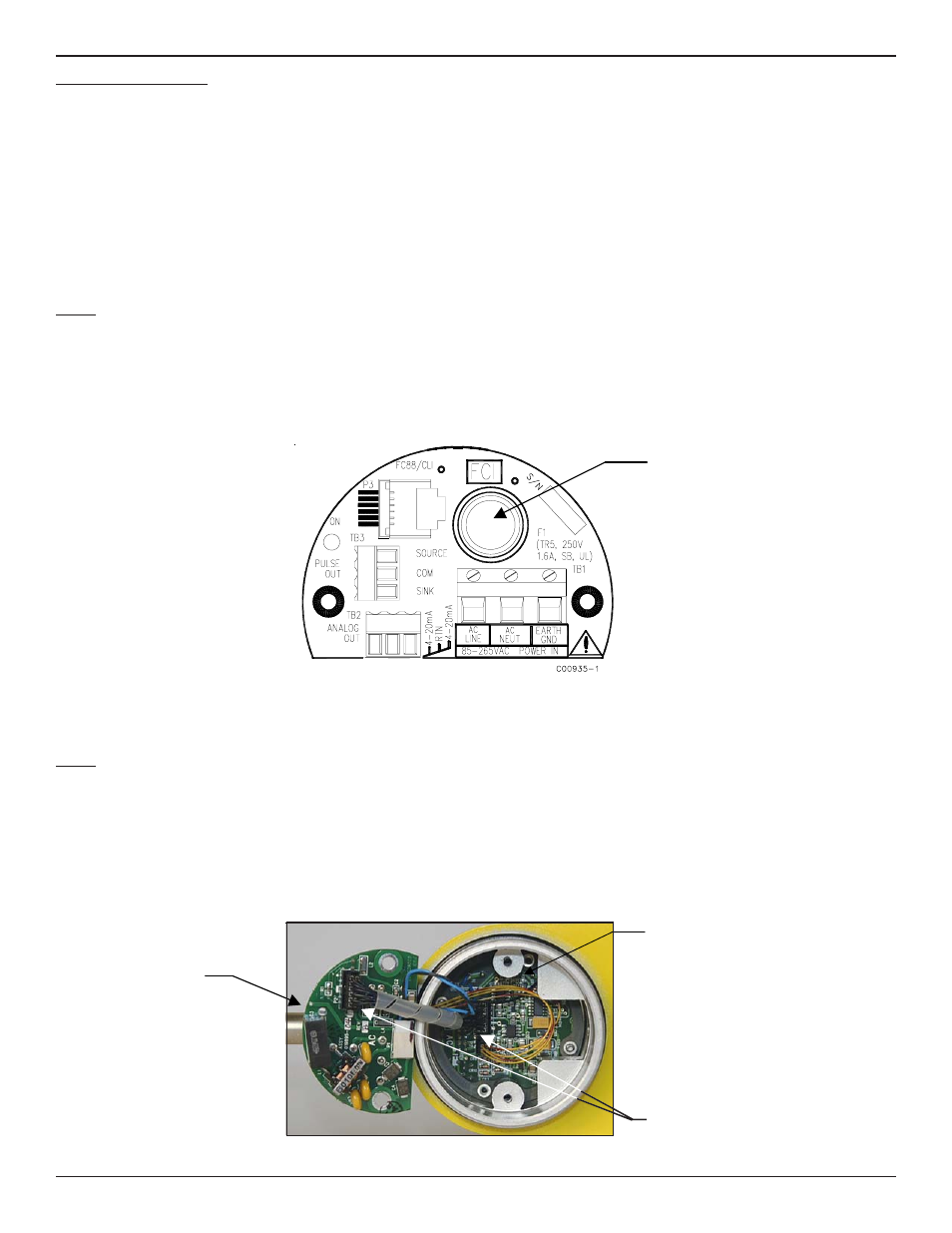

Verify fuse (F1) located on the customer interface circuit board is in normal working condition.

Remove power from the instrument. Open the electronics enclosure exposing the customer interface circuit board. This circuit

board is located under the shorter enclosure lid along with all of the power and input/output connections. Unscrew the clear cover

on the fuse and pull the fuse out of the fuse holder. Check the fuse for continuity. If fuse reads open, replace with equivalent

component (FCI part no. 019933-01), Wickmann Inc. series 374, amp code 1160, package 41.

Ac power customer interface circuit board shown. Fuse (F1) on DC power customer interface circuit board located in similar

position.

Step 2

Verify interconnecting cable from the customer interface board and the control circuit board assembly module are correctly seated

into the appropriate header.

Remove power from the instrument. Open the electronics enclosure exposing the customer interface circuit board. This circuit

board is located under the shorter enclosure lid along with all of the power and input/output connections. Remove the 2 screws

securing the interface circuit board to the electronics enclosure. Carefully lift the interface face board exposing the interconnecting

cable between the interface board and the control circuit assembly. Verify cable is seated firmly at both ends of the cable header.

Fuse (F1)

Cable Header

Interface Board

Control Circuit

Assembly