Fluid Components International ST98 Manual Operation User Manual

Page 2

FLUID COMPONENTS INTL

CHAPTER 3 - OPERATION

Model ST98 Flow Meter

3 - 2

Doc. No. 06EN003291 Rev. A

A user entry is indicated by brackets [ ] being placed around the entry. Y/N refers to Yes (Y), save or change

parameter or No (N) do not save or change parameter unless otherwise specified.

Backspaces are made using the backspace [BKSP] key.

Some entries are case sensitive between numbers and letters. Be sure the SHIFT key is pressed to indicate the

correct case. A square after the prompt caret indicates the FC88 is in lower case. A slightly raised rectangle in the

same spot indicates the FC88 is in the upper case.

It is recommended that the FC88 be plugged into the instrument before power is applied. If the FC88 is plugged in

while the instrument power is on and the FC88 does not respond, press [ENTER], if there is no response press [P],

if there is still no response Press [N].

Note:

Some entries require a pass code (942) to continue programming the instrument. The instrument will

prompt the user when this is necessary. Do not change any parameters that require this code unless there

is an absolute understanding of the instrument's operation. Incorrect changes can cause an inaccurate or

a non-operational instrument. The figures in the "Delta "R" Table would need to be re-input.

The user can not exit some routines unless all entries are completed or the power is recycled.

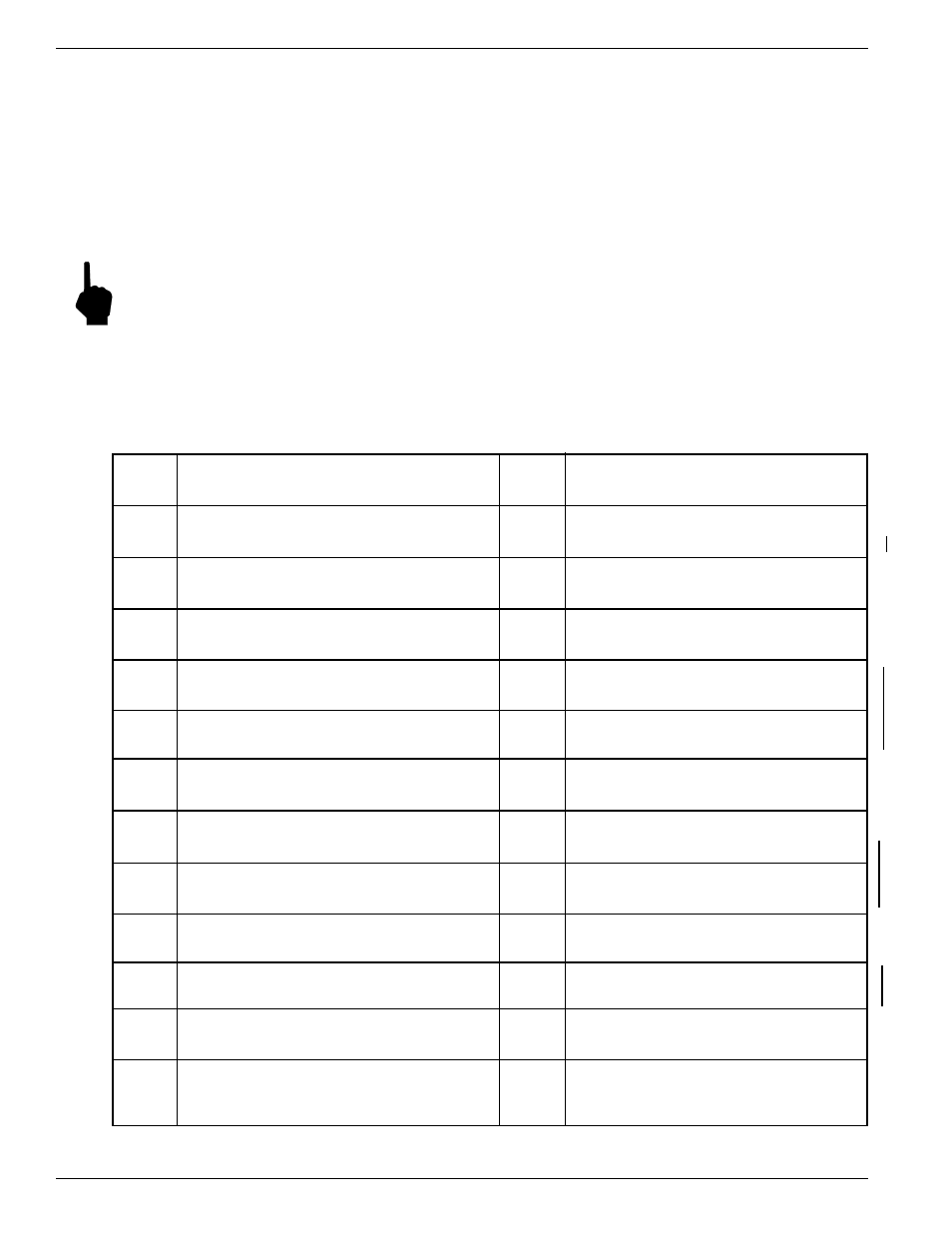

The top level of the menu is shown below. Press the large letter in the Figure 3-1 to activate a command.

N

Software Reset

Re-initialize instrument without removing power

O

Select Sensor Heater Current

HIGH (90 mA) or LOW (75 mA)

P

Re-configure FC88 Unit

Reset the FC88 hand held to ST98 format

Q

Undefined

R

Delta-R, Ref-R, CB Temp, -8/+20 V

Display Delta-R, Ref-R resistor values, etc.

S

Save/Restore USER Save and FACTORY

Calibration data saved and restored

T

Normal Operating Mode

Display flow rate, temperature, totalized flow

U

Display Total Flow Time

Total time (min) in T mode since last reset

V

NAMUR Output Fault Indicator

NAMUR flag, select fault indicator

W

Totalizer Mode

Enable totalized flow w/wo temperature

X

NAMUR Output Fault Indicator

Toggle NAMUR flag(on/off) select fault indicator

Y

Undefined

Z

Flow Units Select

Select flow units (3 English , 3 Metric)

A

Analog Input

Rotate through the 8 analog input channels

B

Sensor Balance

Balance or rebalance Flow Element

C

Calibrate Display

Display A/D Delta-R and Ref-R data values

D

Diagnostic

Check out functional conditions of the unit

E

Sensor Current Select

Displays 2.0 mA - 1k ohm

F

K-Factor

K-Factor entered by user.

G

EEPROM

PW = available when needed

EEPROM byte locations - read/ write.

H

Heater

Toggle heater circuit - OFF/ ON.

I

Output Current Adjust

Manually set output: 4-20 mA, display output load

J

Serial/Customer Numbers

Enter Serial No. and Customer Order No.

K

Constants Setup

Setup curve fit, TC parameters, and other data

L

Calibrate Outputs

Outputs - Heater Current, 4 mA, 20 mA levels.

M

Min/Max A/D Limits

Set minimum and maximum A/D limits

Figure 3-1. Menu Selections Chart