Fluid Components International FS2000L User Manual

Page 8

Fluid Components International LLC

NuTec

®

Series

This page is subject to the proprietary rights statement on the last page

8

Doc. No. 06EN003348 Rev. D

Detecting Decreasing Flow or [Dry] (Low Flow/[Dry] Alarm, jumper at J2)

Stop the process flow [lower level] allowing the instrument to stabilize. Record the TP1 to TP2 voltage. Average the normal and the abnormal pro-

cess condition voltages (i.e., if the normal reading is 7 volts and the abnormal reading is 8 volts, the average or set point is 7.5 volts). The calculated

set point must be at least 0.04 volts over the normal condition. Change the mode jumper to the Calibrate (Cal) position, (J4). Adjust the cal pot (R25)

until the DVM equals the calculated set point voltage. If the Red LED is off, turn the set point pot slowly counterclockwise until the LED turns on. If

the LED is on, turn the pot (R1) clockwise until the LED turns off, then slowly turn the pot counterclockwise until the LED just turn on. Set the calibra-

tion jumper to the operate position (J3).

Detecting Increasing Flow or [Wet] (High Flow/[Wet] Alarm, jumper at J1)

Start an excessive process flow [raise level] allowing the instrument to stabilize. Record the TP1 to TP2 voltage. Average the normal and the abnor-

mal process condition voltages (i.e., if the normal reading is 7 volts and the abnormal reading is 6 volts, the average or set point is 6.5 volts). The

calculated set point must be at least 0.04 volts below the normal condition. Change the mode jumper to the Calibrate (Cal) position, (J4). Adjust the

cal pot (R25) until the DVM equals the calculated set point voltage. If the Red LED is on, turn the set point pot slowly counterclockwise until the LED

turns off. If the LED is off, turn the pot (R1) clockwise until the LED turns on, then slowly turn the pot counterclockwise until the LED just turn off. Set

the calibration jumper to the operate position (J3).

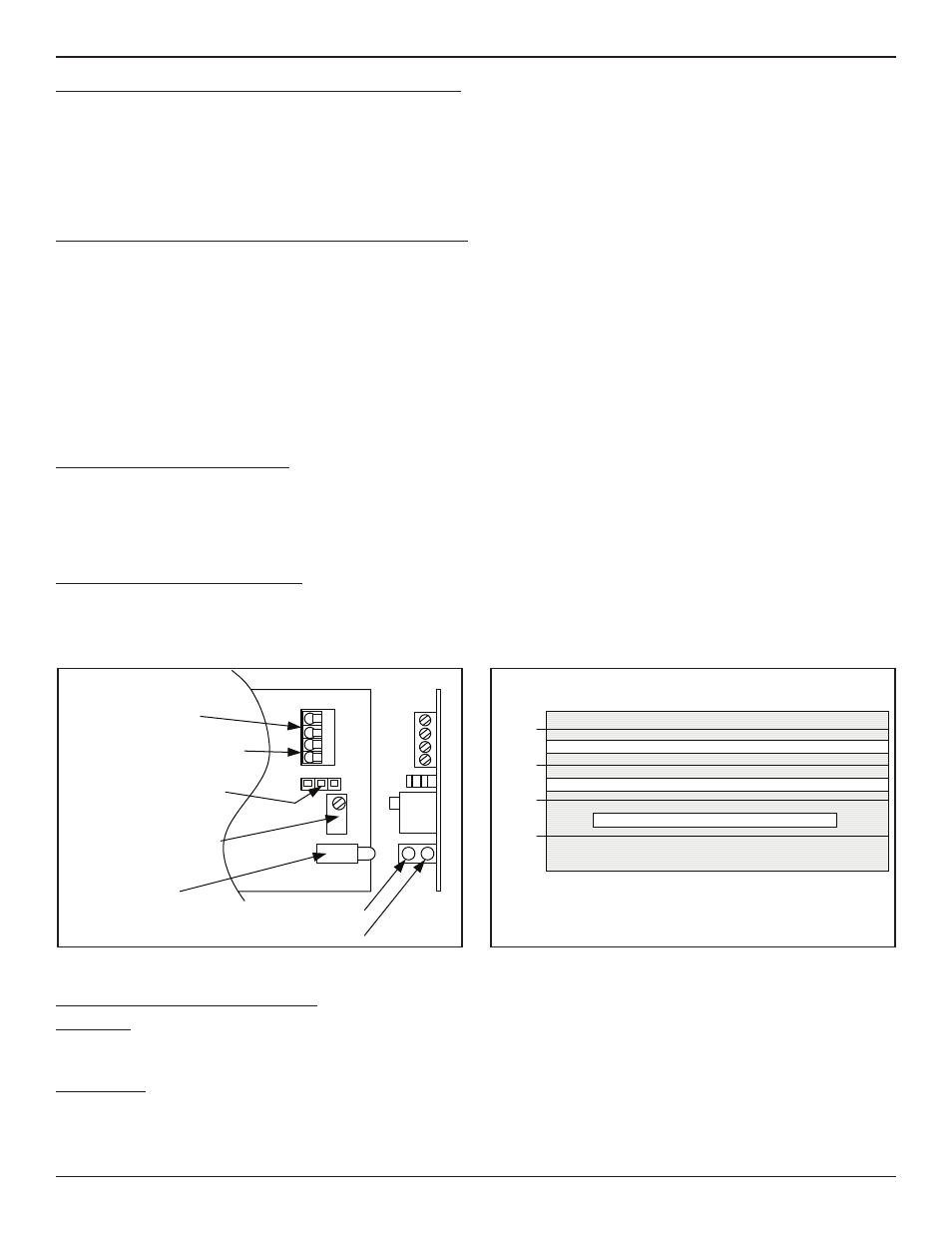

Adjustment by Observation - Input Power, Two Wire (Loop Power)

The following instructions are for both flow and [wet/dry] applications.

NOTE:

Do not adjust R32A and R35A located in the middle of the control circuit.

Detecting Flow or [Wet (high level alarm)]

Set J1 to the “Wet/Flow” position. With the sensing element at no-flow or [dry], turn the set point potentiometer (pot) to the point where the LEDs

toggle back and forth (clockwise to turn on the top LED, CR3, and counterclockwise to turn on the bottom LED, CR2). Turn the pot one turn clockwise

past the point where the top LED (CR3) turns on. Turn on the flow [raise liquid level] and verify that the instrument switches to the alarm state when

flowing or [wet].

Detecting No-Flow or [Dry (low level alarm)]

Set J1 to the “Dry/No-Flow” position. With the sensing element at flow or [wet], turn the set point potentiometer (pot) to the point where the LEDs

toggle back and forth (clockwise to turn on the top LED, CR3, and counterclockwise to turn on the bottom LED, CR2). Turn the pot one turn counter-

clockwise past the point where the bottom LED (CR2) turns on. Stop the flow [lower liquid level] and verify that the instrument switches to the alarm

state when not flowing or [dry].

Section E - Maintenance and Troubleshooting

Maintenance: Typically required for the sensing element. If the process media sticks to the process pipes (or tank) the sensing element should be

cleaned in the same manner and frequency as the process pipe (or tank). Occasionally check for moisture in the control circuit housing and wiring

connections. Check for proper functionality and response time.

Troubleshooting: If the instrument is not operating, go through the installation and adjustment procedures and verify proper installation. If the

instrument fails after some time in service and it has been checked, or if it fails to operate at start up and the installation has been verified, contact

FCI Technical Service. If the instrument is to be returned, obtain a Return Authorization. The form contains a declaration of decontamination cleaning

information that the instrument must comply with before it is shipped to FCI. The telephone number is 1-800-854-1993 or 1-760-744-6950.

OPEN

COLLECTOR

CURRENT

LOOP

-

-

+

+

S

E

T P

O

IN

T

A

DJ

US

T

WET

/

FL

O

W

DR

Y

/

NO

-

FL

O

W

J1

NO-FLOW / DRY (CR3)

FLOW / WET (CR2)

INPUT LOOP POWER

OPEN COLLECTOR

OUTPUT

SENSOR

STATUS

ALARM JUMPERS

SET POINT

ADJUSTMENT POT

PROCESS STATUS

LEDs

P1

C01069-1-1

4

8

12

16

20

CURRENT LOOP (mA)

PROCESS ALARM: 18 mA +/- 0.5mA

PROCESS NORMAL: 14 mA +/- 0.5mA

LOOP STATUS

( mA indications may be reversed. )

HATCHED AREA = INSTRUMENT OR LOOP TROUBLE

C01070-1-1

Figure 13 Loop Power Control Circuit

Figure 14 4-20mA Loop Power Alarm Settings