Specifications – Fluid Components International FS2000L User Manual

Page 2

Fluid Components International LLC

NuTec

®

Series

This page is subject to the proprietary rights statement on the last page

2

Doc. No. 06EN003348 Rev. D

Section B - Instrument Installation

For the FS2000, FS2000H and the LS2000, there is an orientation mark etched onto the sensor element. It is located on a flattened area of

the sensor element body close to the housing.

For the LS2000, the orientation mark can be perpendicular or parallel to the liquid level. The sensor element can be installed top mount 90º to the

liquid surface.

For the FS2000 and the FS2000H, the orientation mark must be parallel to flow, (± 3º). For liquid vertical flows, FCI recommends that the sensor

element be installed where the flow is going in the up direction.

SPECIFICATIONS

Model FS2000 Insertion Flow Switch

(I)

3

LS2000 Insertion Level Switch

(II)

3

FS2000H Insertion Flow Switch, High Flow Rate (III)

3

FS2000L In-Line Flow Switch, Non-Intrusive

(IV)

3

Material of

Construction:

304/305 or 316L Stainless Steel

(I & II)

316L Stainless Steel

(III & IV)

Operating

Temperature:

Sensor Element:

-40° to +250°F [-40° to +121°C]

Control Circuit:

-0° to +140°F [-18° to +60°C]

Maximum

Operating

Pressure:

For Process Connections With:

Male NPT/Compression Fitting: 500 psig [35 bar (g)]

Butt Weld:

500 psig [35 bar (g)]

Flanges (Sanitary):

100 psig [ 7 bar (g)] (IV)

Flanges (ANSI):

Per Specification (I, II)

Input Power: 24 Vac or Vdc. 3 watts Max.

100 to 240 Vac. 5 watts Max.

2-Wire Loop Power

(I, II, IV)

22.5 to 33 Vdc .5 watts Max

Signal

Output:

Available on 24 Volt and 100 to 240 input power units.

Alarm indicator is a 6 amp relay, 28 Vdc / 240 Vdc resistive.

Secondary alarm indicator is an open collector circuit (250

mA Maximum).

FS2000, FS2000H and LS2000 Only 2

2-Wire Loop Power: Alarm indicator responds to change in

current draw between 14 mA and 18 mA.

Installation: Top or Side Mount. Axial flow direction permissible.

Service: General Purpose for Gases and Liquids

Agency

Approvals:

FM, CSA, CE Mark, ATEX, Sanitary 3A, ASME BPE (1997) (IV)

FM, CSA, CE Mark, ATEX, Cenelec

(I, II)

FM, CSA, CE Mark, CRN, ATEX 1

(III)

LS2000 Level Switch

Accuracy: Top Mount:

±0.250 inch [±6mm] from element tip

Side Mount:

±0.125 inch [±3mm] from centerline of

element tip

Response

Time:

Dry to Wet:

Less than 2 seconds

Wet to Dry:

Less than 5 seconds

Wet to Wet: interface: Less than 10 seconds

FS2000 Flow Switch

Setpoint

Range:

Water:

0.1 – 1.5 fps [0.03 – 0.45 mps]

Hydrocarbon: 0.1 – 2.0 fps [0.03 – 0.60 mps]

Air:

0.5 – 100 sfps [0.15 – 30 nmps]

Repeatability:

±1% of Setpoint Range

Response

Time: 0.5 – 2.5 Seconds

FS2000H Flow Switch

Setpoint

Range:

Water:

0.1 – 10 fps [0.03 – 3 mps]

Hydrocarbon: 0.2 – 20 fps [0.06 – 6 mps]

Air:

0.25 – 750 sfps [0.08 – 230 nmps]

Repeatability:

±1% of Setpoint Range

Response

Time: 0.5 – 7 Seconds

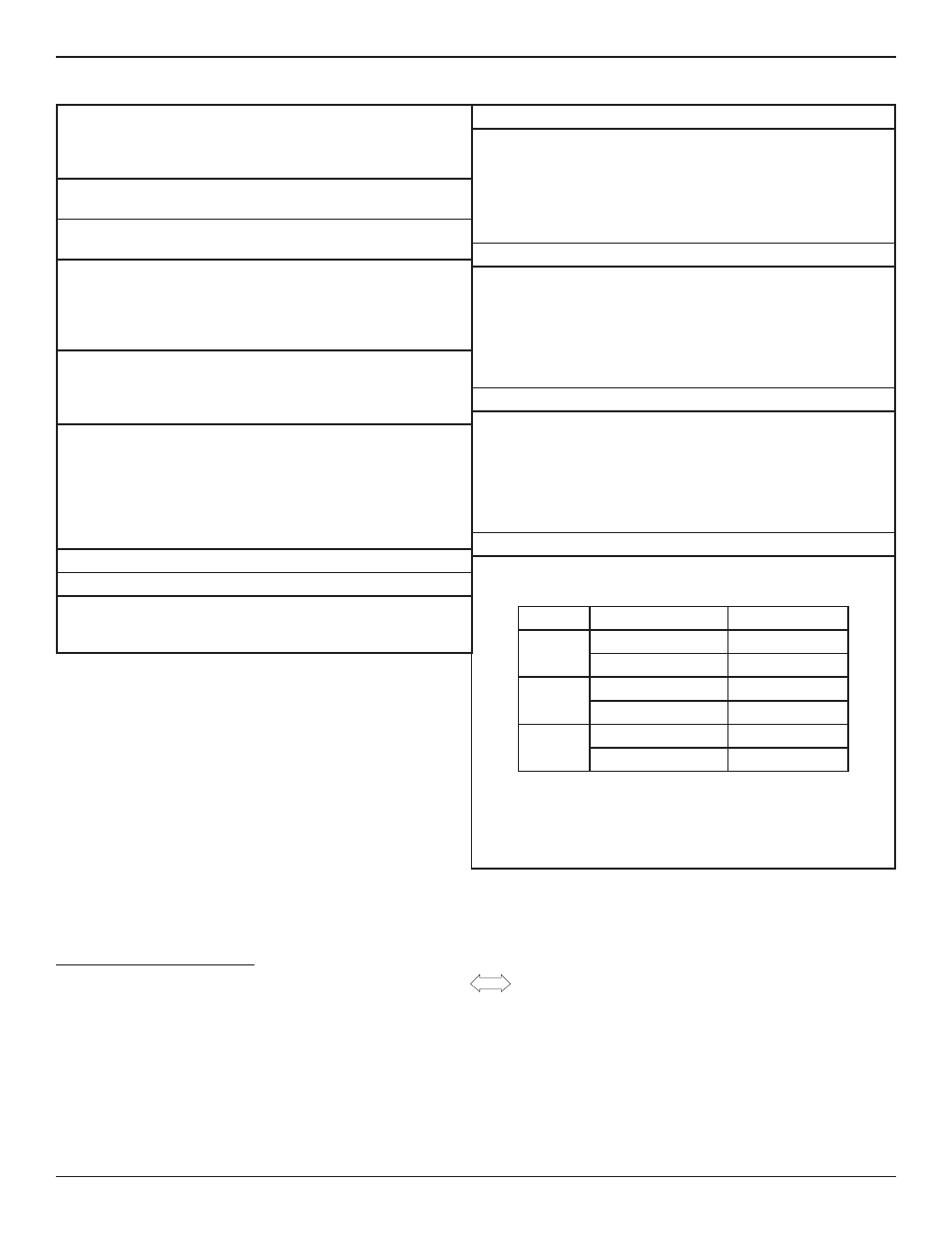

FS2000L Flow Switch (Non-Intrusive)

Setpoint

Range:

Water:

0.1 – 10 fps [0.03 – 3 mps]

Air:

0.5 – 300 sfps [0.15 – 91.4 nmps]

Tubing

Air / Gas

Water

½ inch

1.02 – 13.4 scfm

0.03 – 3.4 gpm

[0.000 – 0.38 scmm]

[0.11 – 12.9 lpm]

1 inch

0.12 – 74 scfm

0.18 – 18.5 gpm

[0.0030 – 2.10 scmm]

[0.68 – 70 lpm]

2 inch

0.57 – 342 scfm

0.85 – 85.5 gpm

[0.0160 – 9.70 scmm]

[3.22 – 324 lpm]

Repeatability:

±1% of Alarm Setpoint

Accuracy:

±3% of Alarm Setpoint ±0.25% of Setpoint Range

Response

Time:

Adjustable from 0.5 – 2.5 Seconds

NOTES:

1. Special Conditions for Safe Use:

2. For applications in explosive atmospheres caused by air/dust mixtures,

cable and conduit entries used shall Customer must provide a 4-20mA

current loop that will maintain 18 to 29.5 volts at the controller control

cuircuit.

3. Roman Numerals reflect model designation.

a. Provisions shall be made to prevent the rated voltage being exceeded

by transient disturbances of more than 40%.

b. For applications in explosive atmospheres caused by air/dust mixtures,

cable and conduit entries used shall provide a degree of ingress

protection of at least IP 54 according to EN 60529.

REF