Verify the sensing element resistances – Fluid Components International FLT Series Rack Mount User Manual

Page 31

FLUID COMPONENTS INTL

CHAPTER 5 - TROUBLESHOOTING

FLT

Series FlexSwitch

Rack Mount

5 - 2

Doc. No. 06EN003250 Rev. N/C

For Factory Calibrated Instruments, Check the Application Data Sheet (ADS)

Design problems usually occur with first-time applications. If the Application Data Sheet does not match the

instrument's actual process conditions, errors occur. See the plastic sleeve at the back of the manual for a copy of the

ADS.

1.

Review the instrument's ADS with plant operation personnel and plant engineers.

2.

Verify that the process media, as well as the range of process temperature and pressure, agrees with the

instrument's ADS.

Verify the Sensing Element Resistances

The following procedure provides a step-by-step checkout. The measurements are based on a standard sensing

element (1.1K ohm RTDs at 80°F). Variation of ±500 ohms from nominal is to be expected. The maximum

allowable difference in resistance between matched RTDs is 1% at ambient temperature (immersed in water). The

heater resistance should be 110 ±5 ohms for the S model sensing element and 560 ±13 ohms for the F model sensing

element.

Check the Resistance at the Control Circuit Connector

Warning: Turn the instrument's power OFF.

Gently remove the control circuit from the rack. Use a multimeter to measure the resistance of the sensing element's

heater and RTDs (see Tables 5-1 and 5-2 for nominal values).

Note:

If enough time has not been allowed for the sensing element to cool, then the resistance of the active

RTD will be greater than the resistance of the reference RTD.

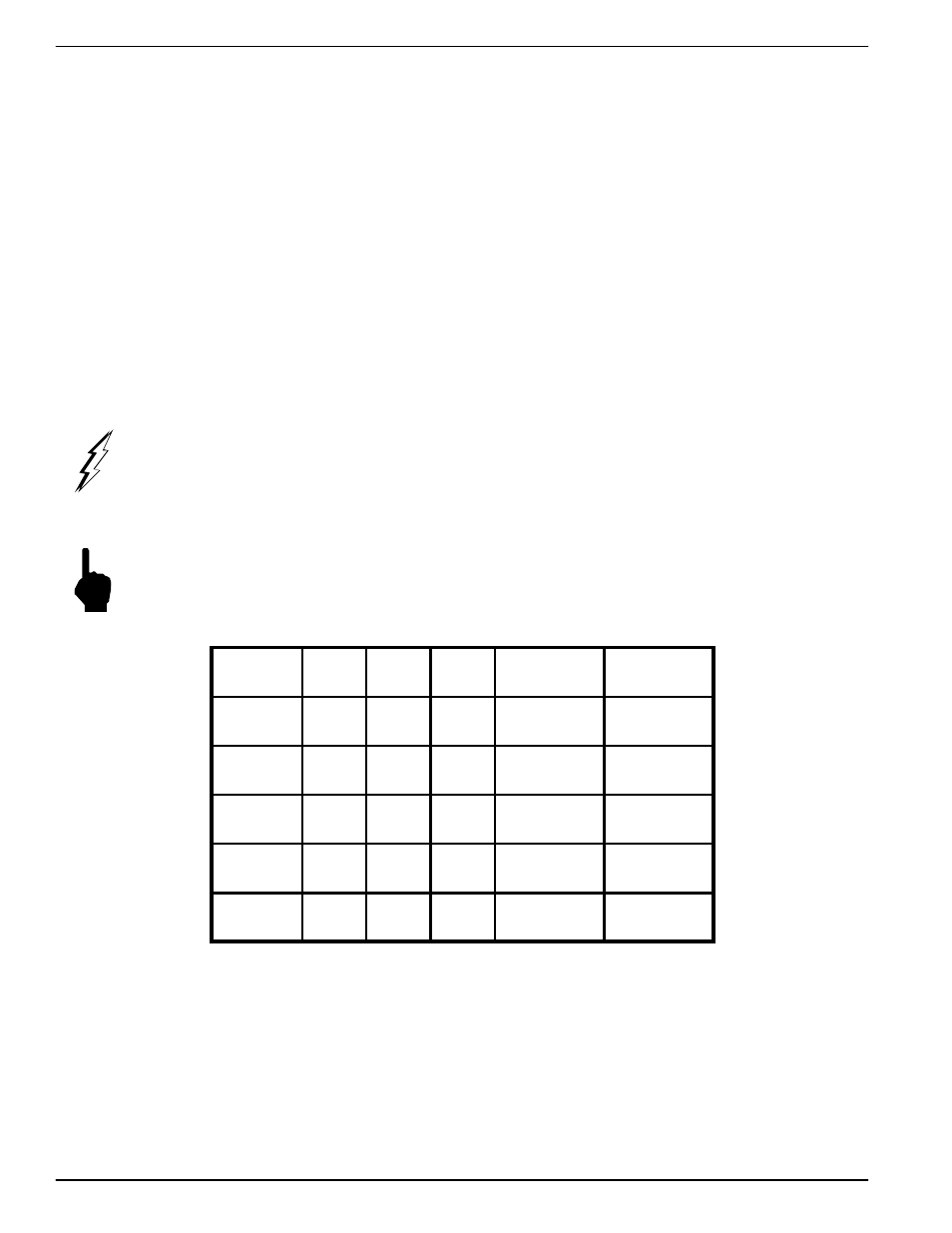

Table 5-1. Matrix of Nominal Resistance Values (ohms at 80°F) at P1 CH. A

Pin No.

P1-B10

(ACT)

P1-D8

(COM)

P1-D10

(REF)

P1-Z8

(HTR +)

P1-B8

(HTR RTN)

P1-B10

(ACT)

0

1.1K

2.2K

OPEN

OPEN

P1-D8

(COM)

1.1K

0

1.1K

1.3K

OPEN

P1-D10

(REF)

2.2K

1.1K

0

2.4K

OPEN

P1-Z8

(HTR +)

OPEN

OPEN

OPEN

0

110 S MODEL

560 F MODEL

P1-B8

(HTR RTN)

OPEN

OPEN

OPEN

110 S MODEL

560 F MODEL

0