Alarm set point adjustments – Fluid Components International FLT Series User Manual

Page 20

FLUID COMPONENTS INTL

CHAPTER 3 - OPERATION

FLTÔ Series FlexSwitchÔ

3 - 2

Doc. No. 06EN003246 Rev. B

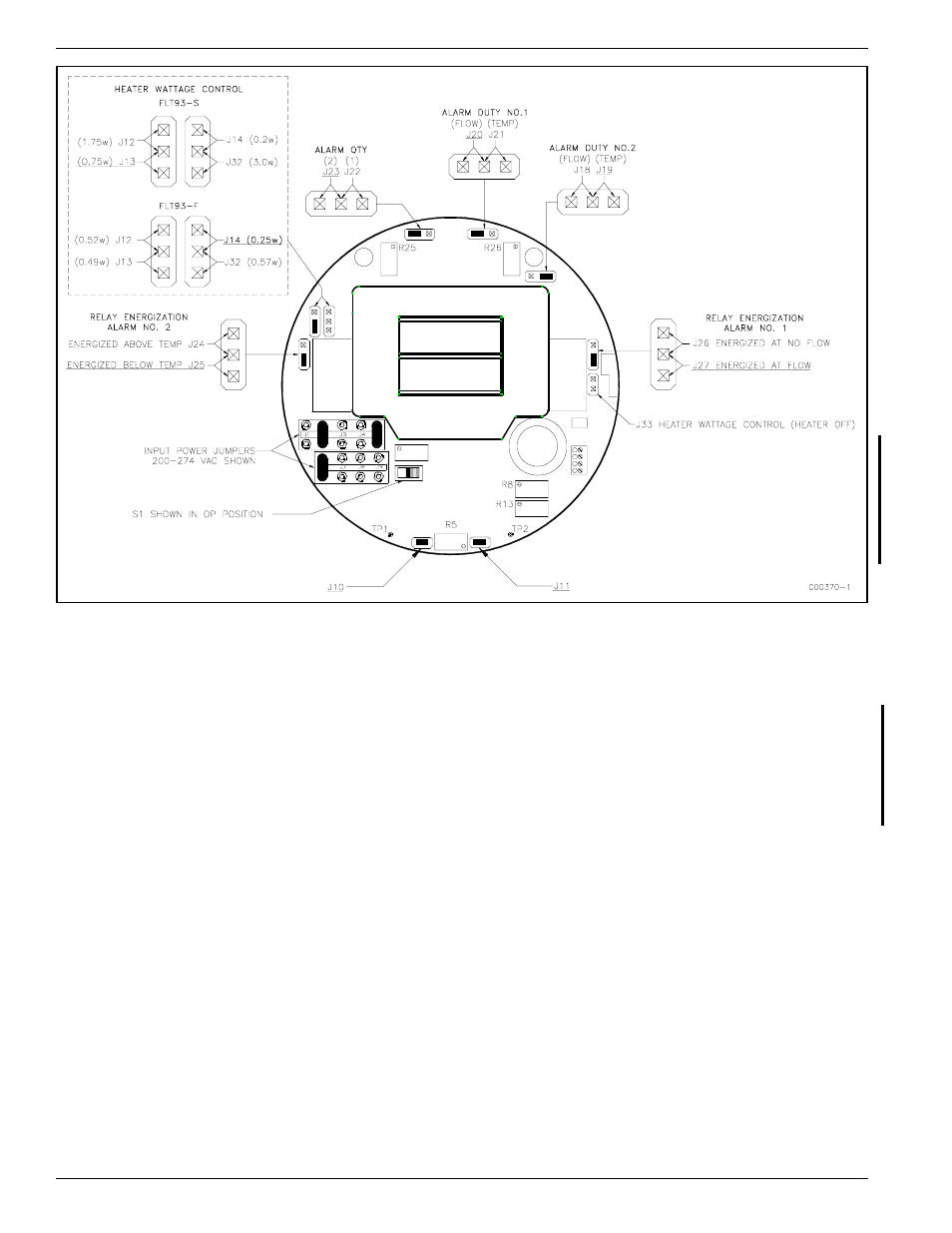

Figure 3-1. 5294 Control Circuit Jumper Locations

The reason for operation in the above extreme conditions is that the input signal range is at the widest point making

the alarm set point adjustment easier to perform. If the heater does cycle the operator may need to use the next lower

wattage setting.

In some applications it is desirable to set the heater wattage high, even though the sensing element goes into the

heater cutoff mode. An example is when the instrument is used to detect the interface of two liquids. These liquids

may have viscosities that will have signals very close to each other. In order to have the maximum signal difference

between the signals the heater wattage is set to its maximum. If the sensing element detects a dry condition the

control circuit will indicate a heater cutoff condition. The sensing element will not be dammaged if it is left dry with

the maximum heater wattage. The alarms can be set so one alarm will switch at the interface and one alarm can

detect when the element goes dry.

Alarm Set Point Adjustments

Numerical Adjustment Versus Adjustment by Observation

An alarm set point is established using either numerical adjustment or adjustment by observation. The adjustment by

observation requires the customer to establish normal process operation and adjust the alarm set point relative to this

condition. The numerical approach requires measuring normal and alarm process conditions with a voltmeter and

setting up the instrument in the calibrate mode based on these values. The adjustment by observation requires less

time to establish the alarm set point. The numerical adjustment requires control of the process as well as additional

time to establish the alarm set point. Use the adjustment procedure that is the most appropriate for the application

requirement.