Fluid Components International FLT Series User Manual

Page 16

FLUID COMPONENTS, INTL

CHAPTER 2 - INSTALLATION

FLTÔ Series FlexSwitchÔ

2 - 6

Doc. No. 06EN003246 Rev. B

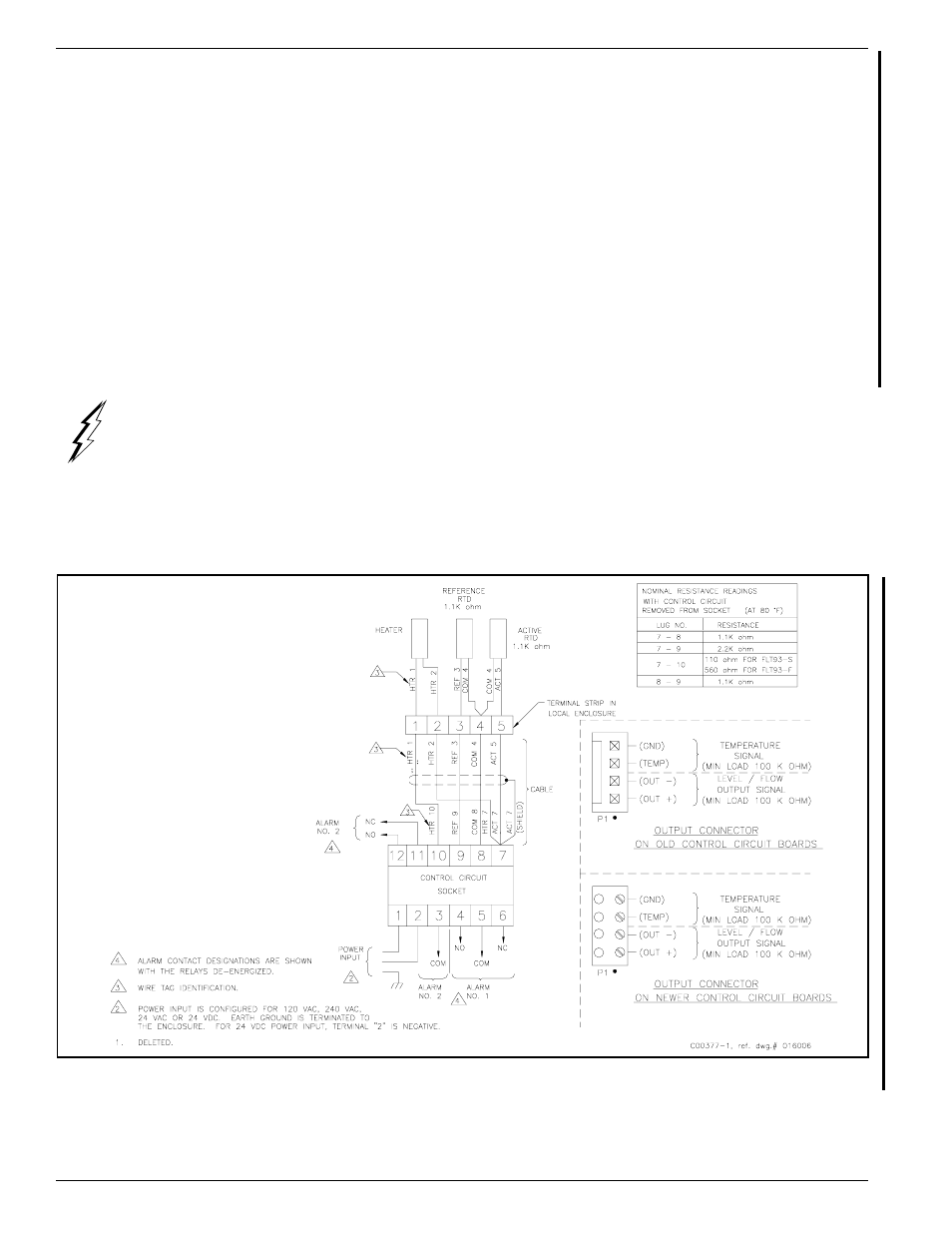

Wiring The Remote Enclosure

This procedure is for instruments with the control circuit located remotely from the sensing element.

Locate the Remote Hardware Location

Appendix A shows the remote enclosure along with the physical dimensions to properly mount it. Select a location

for the remote enclosure within a 1000 feet (305 m) of the sensing element. Pigtail sensing elements can not be

located more than 10 feet (3 m) from the enclosure unless the pigtail is extended with the proper size cable listed in

Table 2-1. If the cable is extended the cable connections should be located in a junction box with a 6 position

terminal block. All 5 conductors and the shield must have its own termination. The remote enclosure should be

easily accessible with enough room to open the enclosure cabinet cover at any time. Secure the remote enclosure

solidly to a vertical surface capable of providing support. Use appropriate hardware to secure the enclosure.

1.

Remove the control circuit from the remote enclosure.

2.

Run a five-conductor, shielded cable from the local enclosure to the remote enclosure. Use Table 2-1 to

determine which wire gauge to use.

3.

Wire between the local and remote enclosures according to Figure 2-6.

Warning: Ensure that all power is off before wiring any circuit.

4.

When connecting the relay wiring, do so with complete understanding of what the process requires of the

instrument. The instrument has dual SPDT or single DPDT relay output contacts dependent on the jumper

configuration for each alarm switch point. For the relay logic, refer to Figure 2-6. Also refer to Table 3-5 and

Table 3-6 in Chapter 3 - Operation. Relay contacts are shown with the relays de-energized. Wire in accordance

with the system requirements.

Figure 2-6. Remote Wiring Diagram