Install the sensing element – Fluid Components International FLT Series User Manual

Page 12

FLUID COMPONENTS, INTL

CHAPTER 2 - INSTALLATION

FLTÔ Series FlexSwitchÔ

2 - 2

Doc. No. 06EN003246 Rev. B

Prepare or Verify Sensing Element Location

Prepare the process pipe for installation, or inspect the already prepared location to ensure that the instrument will fit

into the system.

Review the requirement for the supply power and alarm circuit connections.

Verify Dimensions

Verify the instrument's dimensions versus the process location to be sure of a correct fit. Also see Appendix A for

dimensions.

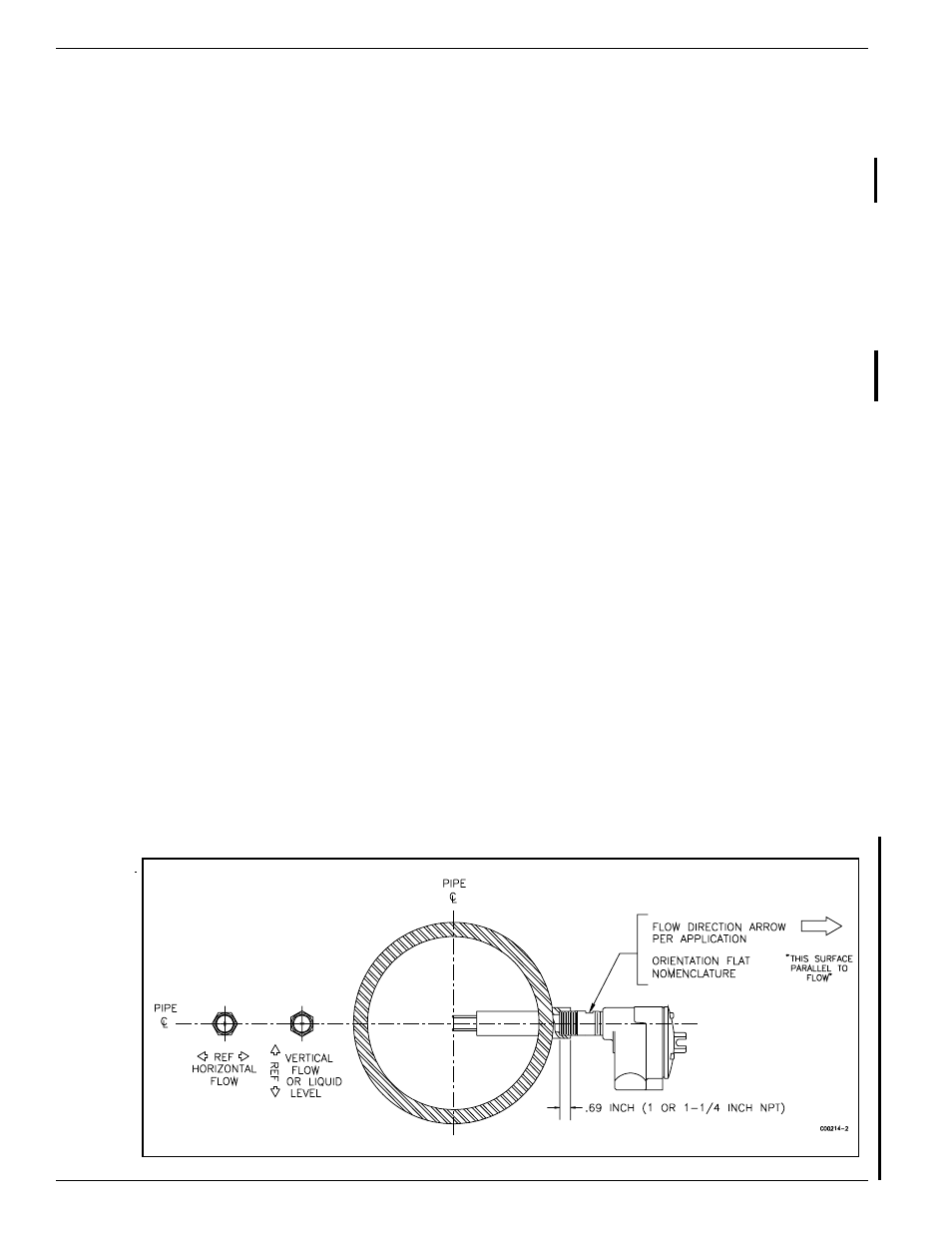

Verify Sensing Element Flow Direction and Placement Orientation (Flow Application)

For flow detection, the sensing element surface marked with direction arrows should be oriented parallel to the

process flow. The flow can be from either direction. See the appropriate figure in Appendix A for the flow arrow

marking.

Mount the sensing element at least 20 diameters downstream and 10 diameters upstream from any bends or

interference in the process pipe or duct to achieve the greatest accuracy.

For liquid flow service, the sensing element should be located in the process pipe so that the thermowells are always

completely wet.

When mounted in a tee or section of pipe larger than the normal process pipe, position in a vertical run of pipe with

flow upward. This will prevent air or gas bubbles from becoming trapped at the sensor assembly.

Vertical positioning with flow downward is only recommended for higher flow rate applications (consult FCI).

Verify Sensing Element Flow Direction and Placement Orientation (Level Application)

If the sensing element is side-mounted on the process vessel, then the surface marked with direction arrows should be

vertically oriented.

If the sensing element is top- or bottom-mounted on the process vessel, the orientation of the surface marked with

direction arrows does not matter.

Install the Sensing Element

Male NPT Mounting

When mounting the sensing element to the process pipe, it is important that a lubricant/sealant be applied to the male

threads of all connections. Be sure to use a lubricant/sealant compatible with the process environment. All

connections should be tightened firmly. To avoid leaks, do not overtighten or cross-thread connections. See

Figure 2-1 and the appropriate figure in Appendix A for proper mounting.

Figure 2-1. NPT Pipe Thread Mount