Burkert Type 8635 User Manual

Page 3

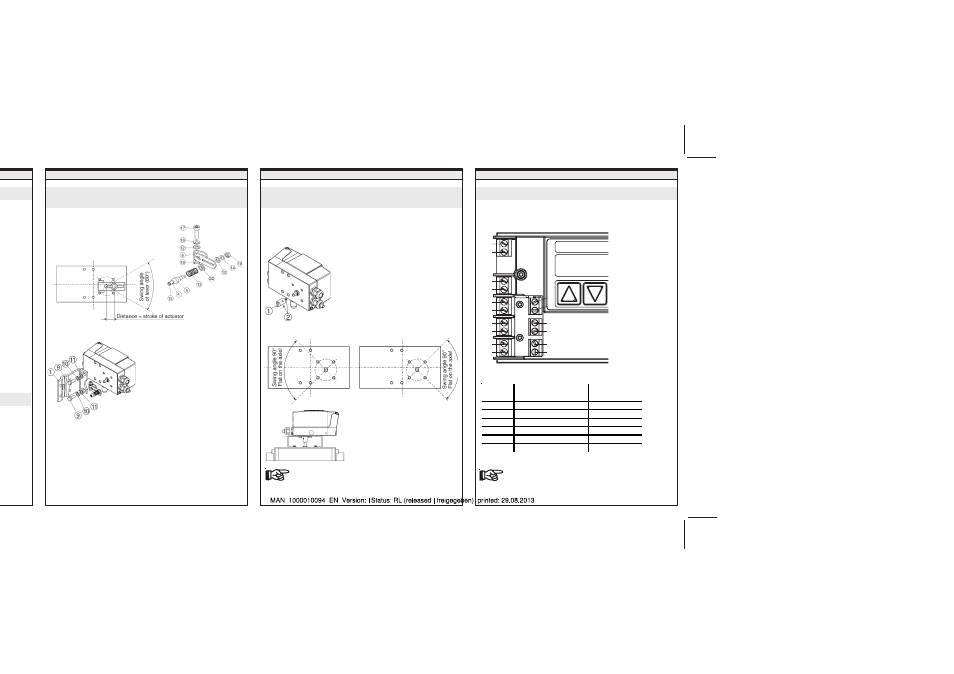

VALVE CONNECTION

Attachment to a continuous valve with linear

actuator acc. to NAMUR

d (NC):

(NO):

VALVE CONNECTION

Configuration of the terminals

ELECTRICAL CONNECTION

valves:

at piping

e the

mber of the

ctuator

• Assemble the lever (if not preassembled). The distance of

the driving pin from the axle should

be equal to the stroke. This results

in a swing angle of the lever of 60°.

The scale printed on the lever

is irrelevant.

• Fix the lever onto the axle of the SIDE

Control.

• Fix attachment bracket (1) to the SIDE

Control.

Alignment of the lever mechanism

The lever mechanism can be aligned properly only when the

device has been connected electrically and pneumatically.

• In the manual mode, move the actuator to half stroke

(corresponding to scale on actuator).

• Move the device vertically until the lever is horizontal.

• Fix the device finally to the actuator.

Attachment to a continuous valve with part-turn

actuator

• Select the M8 thread on the

SIDE

Control such that the

conical roller (5) on the lever of

the position sensor can move

freely in U-piece (2) on the

actuator over the entire stroke.

• Mount the U-piece on the drive

spindle of the actuator.

• Attach the SIDE

Control to the cast

frame or post yoke of the actuator

according to NAMUR procedure.

• To make electrical connection, open the cover of the

SIDE

Control by unscrewing the 2 screws.

Connection of a potential equalization conductor

(PE) to the electronics is not required.

If after starting the function

X.TUNE the message

X.ERR 5 appears in the LC display, the alignment of

the axle of the SIDE

Control to the axle of the

actuator is incorrect.

• Push adapter (1) onto the axle of the

SIDE

Control and fix it with 2

setscrews (2). One of the setscrews

should press onto the flat on the axle

(to prevent slip!). It must be assured

that the axle of the SIDE

Control can

move only in one of the ranges

shown below in the drawings.

Observe the flat on the axle!

• Determine the orientation of attachment of the SIDE

Control

(parallel to the actuator or rotated by 90°).

• Determine the basic position and direction of rotation of the

actuator.

• Place the SIDE

Control on the

bracket and fix it.

• Mount the SIDE

Control with the

bracket on the part-turn

actuator.

1st possibility:

2nd possibility:

Terminal

Allocation

External

connection

11 +

Setpoint +

4 ... 20 mA signal

12 -

Setpoint -

GND

13 +

Process value + (option) 4 ... 20 mA signal

14 -

Process value - (option)

GND

31

Actual value output +

32

Actual value output -

11

12

81

82

13

14

41

42

51

52

31

32

86

85

83

84