Burkert Type 8631 User Manual

Page 3

to

se

FLUIDIC CONNECTION

Operating conditions

Ambient temperature

-10... +50°C

Protection class

IP 65 nach EN 60529

Electrical data

Voltage supply

(see nameplate)

24 V DC ± 10 %

3)

110 / 230 V AC

4)

Protection class

3 to VDE 0580

Pneumatic data

Control medium

Quality classes

to DIN ISO 8573-1

- Dust content

max. particle size 40 µm

max. particle density 10 mg/m

3

- Water content

max. pressure dew point -20 °C

- Oil content

max. 25 mg/m

3

Temperature range of

compressed air

-10 ... +50 °C

Pressure range

3 ... 7 bar

Installation of the valve

• Installation in any orientation but preferably upright.

• Observe the flow direction of the fitting.

• Clean piping from contamination!

• Before attaching the valve housing, make sure the piping is

aligned.

• If the housing is to be welded on, make absolutely sure

that the actuator is removed beforehand.

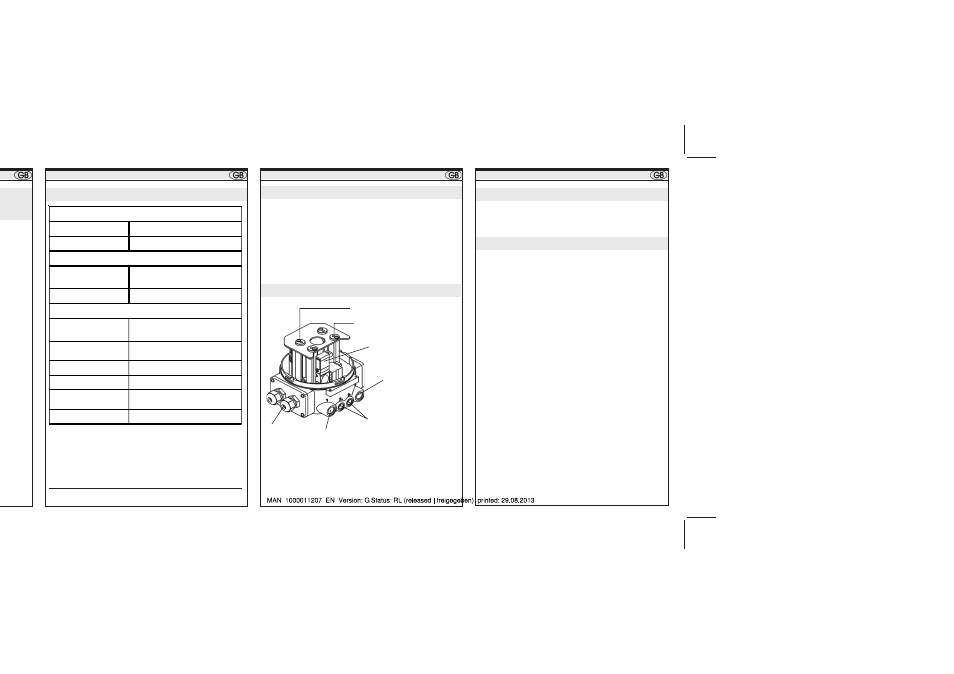

Connection of the control air

Electrical

connection

module

Screw for adjusting the lower

proximity switch

Screw for adjusting the upper

proximity switch

Pilot valve (3/2- or 5/2-way

solenoid valve)

Pressure supply port

(marked 1)

Control ports (connected in

the factory)

Exhaust air port

(marked 3)

Possible expansion steps

• Mechanical over travel switch

• AS interface

• DeviceNet

Various process valves from the Bürkert range can be combined

with the TOP

Control ON/OFF to suit different applications. Y-, flat-

seat, diaphragm or ball valves are suitable.

Fixing the TOP

Control

ON/OFF

TECHNICAL DATA

ed by the

The fixing screw (connection between Top

Control and

process valve) may only be tightened with a maximum

torque of 1.2 Nm.

Technical Data

3)

Attention: do not use insustrial DC.

4)

At present not available

We reserve the right to make technical changes without notice.

FLUIDIC CONNECTION