Valve construction, English – Burkert Type 6510 User Manual

Page 8

8 - 6510/6511

T

ECHNICAL

D

ESCRIPTION

english

Valve Construction

• 3/2 way pilot valve with various electrical connection possibilities

• valve body with diaphragm, seat seal and weldet cover plates

• 2(B) / 4 (A) service ports plus supply and venting ports 1 (P) / 3 (S) / 5 (R), as option with internal

thread or plug-in connectors

• the valves can be mounted on the modular pneumatic basic rail s type MP01 or MP02 to form valve

blocks

• Can be mounted in any position, preferably with the magnetic system at the top

• Manual override for hand operation of the valve

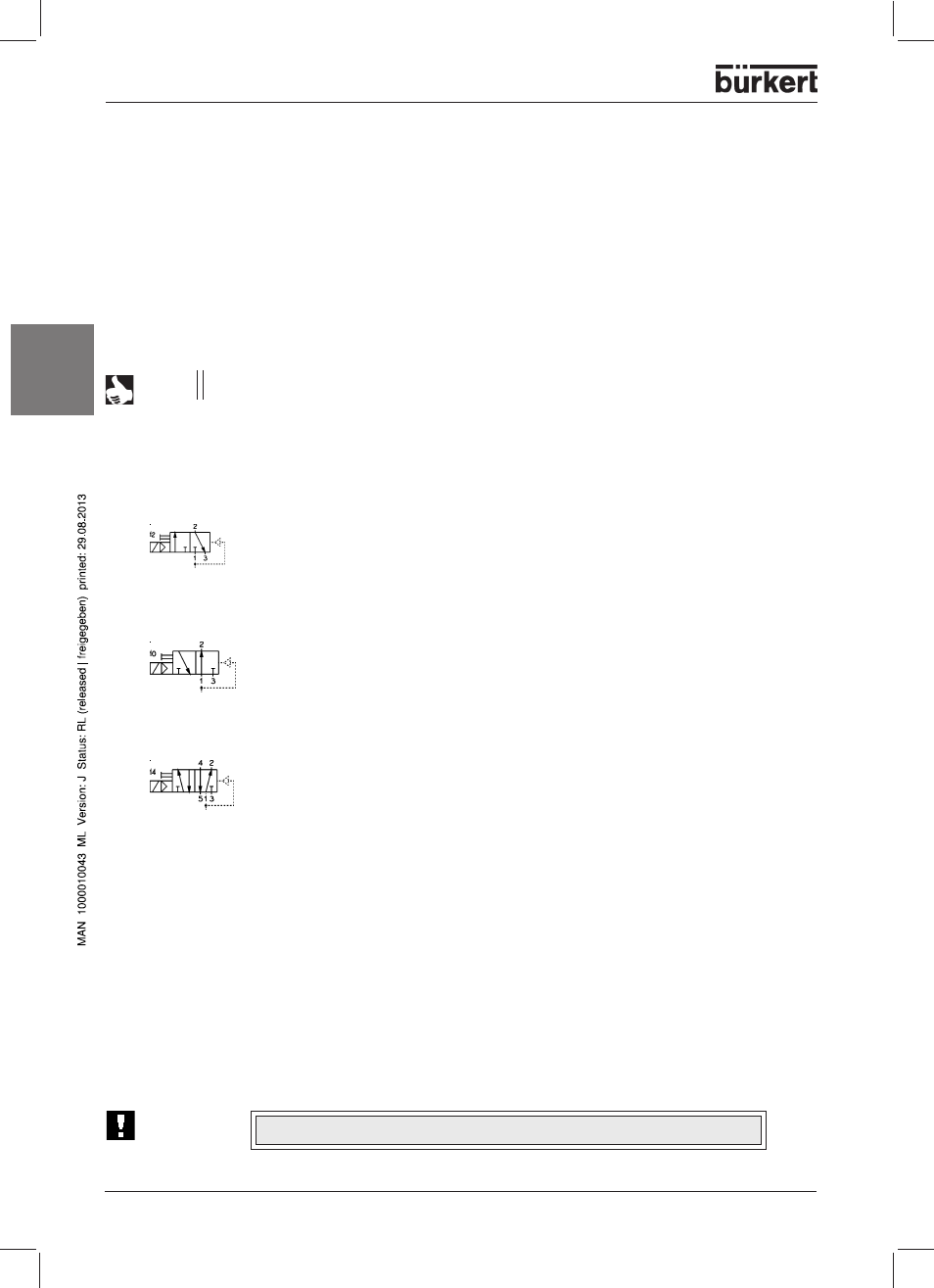

3/2 way valve:

In de-energised position, Pressure Inlet 1 closed, Outlet Port 2 exhausted

3/2 way valve:

In de-energised position, Pressure Inlet 1 connected to Outlet Port 2

5/2 way valve:

In de-energised position, Pressure Inlet 1 connected to Outlet Port 2, Outlet Port 4 exhausted.

Valve operations of the Type 6510 / 6511 valves

Media

• Filtered compressed air (max. particle size 5 µm), preferably non-oiled

• Operation is possible with oiled air

• Seal materials: NBR and FKM

• Permissible medium temperature: max. +50° C

• Permissible ambient temperature: max. +55° C

• Operational pressure range: 2,5 - 7 bar

ATTENTION!

For temperatures below 0° C, operation is limited to dry-air operation!

NOTE

The valves require no maintenance, even for dry-air operation.