Electrical data, Installation – Burkert Type 6114 User Manual

Page 4

english

12

ELECTRICAL DATA

Ensure that the polarity is correct, otherwise

the device will not function!

Observe color coding of the cable: (black / red)

Operating voltage

According to type label

Standard version ± 10 %

Clocked version + 10 %

Nominal power

1.1 W

Nominal operating mode Continuous operation, ED 100 %

Actuation of bistable version:

Polarity

Identification

Pulse duration min. 20 ms

(black)

(red)

+

Valve (P seat) is

closed

Valve (R seat) is

open

–

Valve (P seat) is

open

Valve (R seat) is

closed

english

13

INSTALLATION

Safety Instructions

WARNING!

Risk of injury from improper assembly!

• Installation may be carried out by authorised technicians

only and with the appropriate tools!

Risk of injury from unintentional activation of the

system and an uncontrolled restart!

• Secure system from unintentional activation.

• Following assembly, ensure a controlled restart.

Fluid Installation

WARNING!

Risk of injury from high pressure!

• Before loosening the lines and valves, turn off the pressure

and vent the lines!

Important operating condition for the preven-

tion of malfunctions: The valve must have a mini-

mum distance of 5 mm from other ferromagnetic

materials.

english

14

Installation location: any, drive preferably upwards.

Prior to the installation:

→

Clean any dirt off the pipelines and flange connections.

→

To prevent malfunctions, install a filter (5 µm) in front of

the valve.

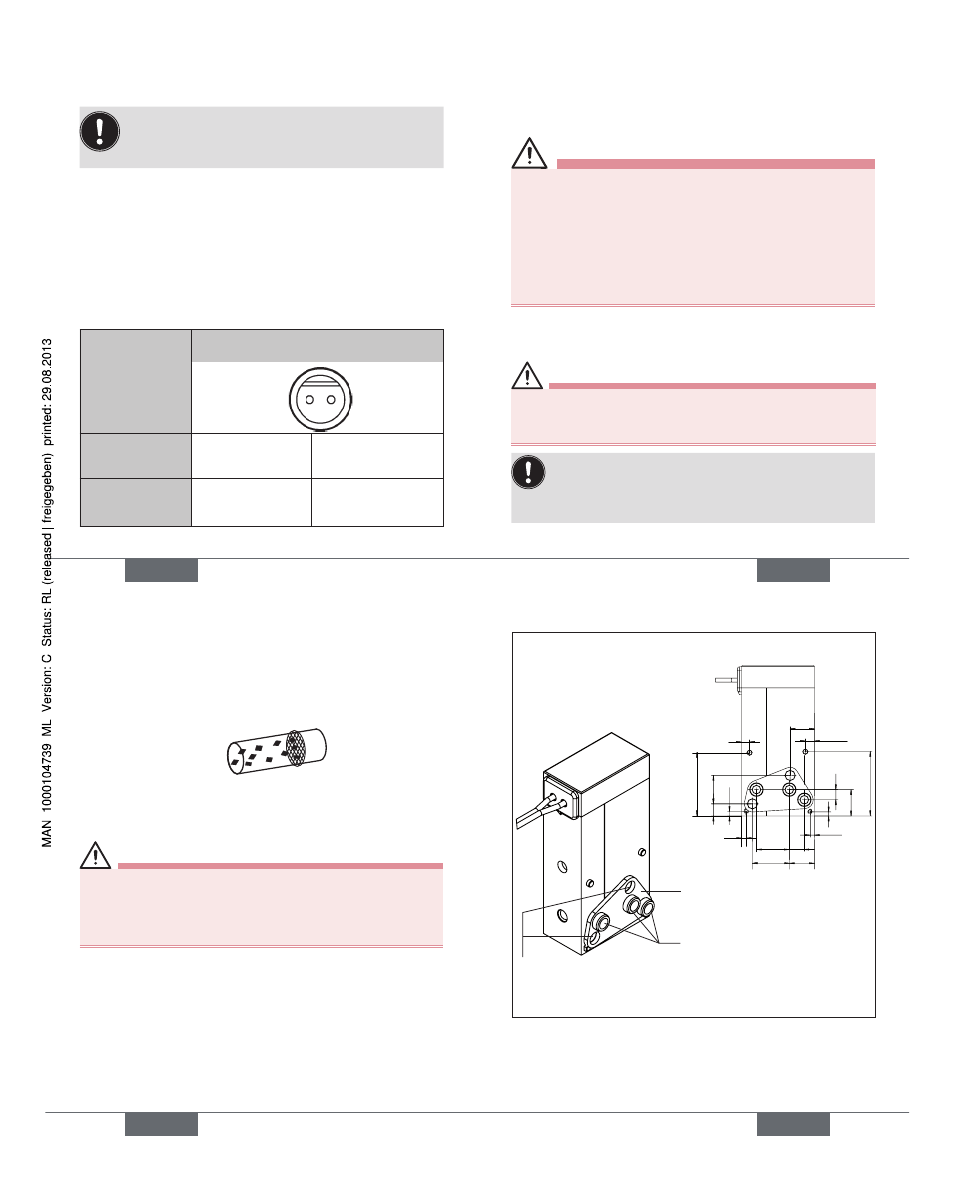

Assembly of Type 6114:

(See diagram: Assembly drawing)

WARNING!

Danger - escaping medium!

Leaking connections if seal seated incorrectly.

• Ensure that the supplied sealing gasket is seated

correctly.

→

Insert the sealing gasket into the valve.

→

Correctly allocate the fluid connection configuration 1,

2 and 3 to the valve and the connection plate.

→

Drill holes according to the drill hole-pattern.

→

Screw valve onto the connection plate

→

Check valve for leakage.

english

15

Valve with fastening elements

Fluid connections

(see "Pneumatic data")

2,25

2

15,6

6

6,2

3,7

8,1

1,1

9,1

1,1

7

3

2,5

6,5

15,

85

1

1

Bore hole

illustration:

Bores for fastening

screws

Ø 2 mm

Sealing gasket

Figure: Assembly drawing

Type 6114