Burkert Type 2037 User Manual

Page 19

19

Installation

procedure for control function a

→

Pressurize lower control air connection with compressed air

(value as indicated on the type label) (see “Fig. 17”).

→

Place actuator on the body.

→

Lightly cross-tighten the body screws until the diaphragm is

between the body and actuator.

do not tighten the screws yet.

→

Actuate the diaphragm valve twice to position the diaphragm

correctly.

→

Without applying pressure, tighten the body screws to the permitted

tightening torque (see “Tab. 7”).

→

Pressurize lower control air connection with compressed air (value

as indicated on the type label).

→

Check the tightening torque of the screws again.

procedure for actuator with control functions B and I:

→

Place actuator on the body.

→

Lightly cross-tighten the body screws without pressurization until

the diaphragm is between the body and actuator.

do not tighten the screws yet.

→

Pressurize upper control air connection with compressed air (value

as indicated on the type label) (see “Fig. 17”).

→

Actuate the diaphragm valve twice.

→

Tighten the body screws to the permitted tightening torque (see

“Tab. 7”)

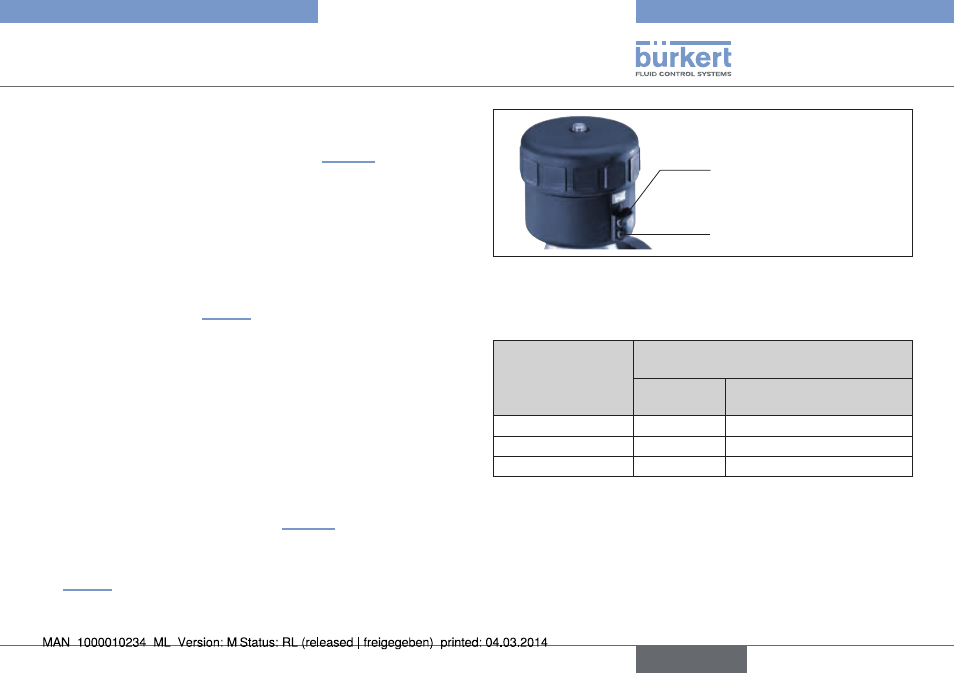

Upper control air connection

(for CFB and CFI)

Lower control air connection

(for SFA and SFI)

Fig. 17: Control air connection

tightening torques for plastic body, Va tubular body (Va) and

forged body

orifice

(diaphragm size)

dn [mm]

tightening torque [nm]

(values for guidance)

EpdM/fkM

ptfE / advanced ptfE /

laminated advanced ptfE

65

20

30

80

30

40

100

40

50

Tab. 7: Tightening torques for diaphragms

english

Type 2030, 2031, 2031 K, 2032,

2033, 2037