3 replacing the valve seat – Burkert Type 2012 User Manual

Page 17

17

Maintenance,Cleaning

Type 2012

9.3

replacing the valve seat

remove the actuator from the valve body

→

Clamp the valve body in a holding device.

note!

damage to the seat seal or the seat contour!

▶ When removing the actuator, ensure that the valve is in open

position.

→

Control function A: pressurize the lower control air connection

with compressed air (6 bar): valve opens.

→

Using a suitable open-end wrench, place the wrench flat on the

tube.

→

Unscrew the actuator from the valve body.

replacing valve seat

→

Unscrew old valve seat using the installation tool and open-end

wrench.

→

Clean thread and sealing surface in the body using compressed air.

→

Select tool insert and screw into the installation tool.

→

Attach new valve seat to the installation tool.

→

Grease thread with a lubricant (e.g. Klüber paste UH1 96-402).

→

Place attached valve seat on the body thread and screw on by

hand.

→

Using a torque wrench, tighten to the specified tightening torque

(see “Tab. 2”).

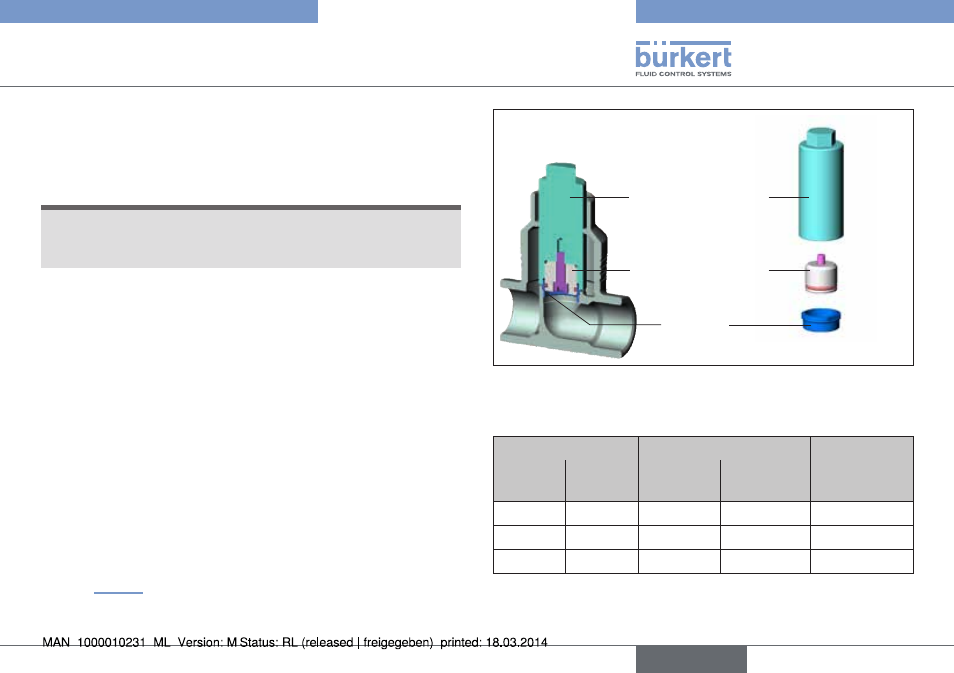

Installation tool

Tool insert

(according to nominal

width of seat)

Valve seat

Fig. 7: Replacing the valve seat

tightening torque for installation of seat

screw connection

tightening torques

tolerance

seat

Body

uncoated

seats

coated

seats

DN 65

DN 65

150

150

+10

DN 80

DN 80

180

180

+10

DN 100

DN 100

220

220

+10

Tab. 2: Tightening torque for installation of seat

english