Brooks, Model 5851e, Caution – Brooks Instrument 5851E User Manual

Page 51

Brooks

®

Model 5851E

4-19

Section 4 Maintenance

Installation and Operation Manual

X-TMF-5851E-MFC-eng

Part Number: 541B104AAG

November, 2008

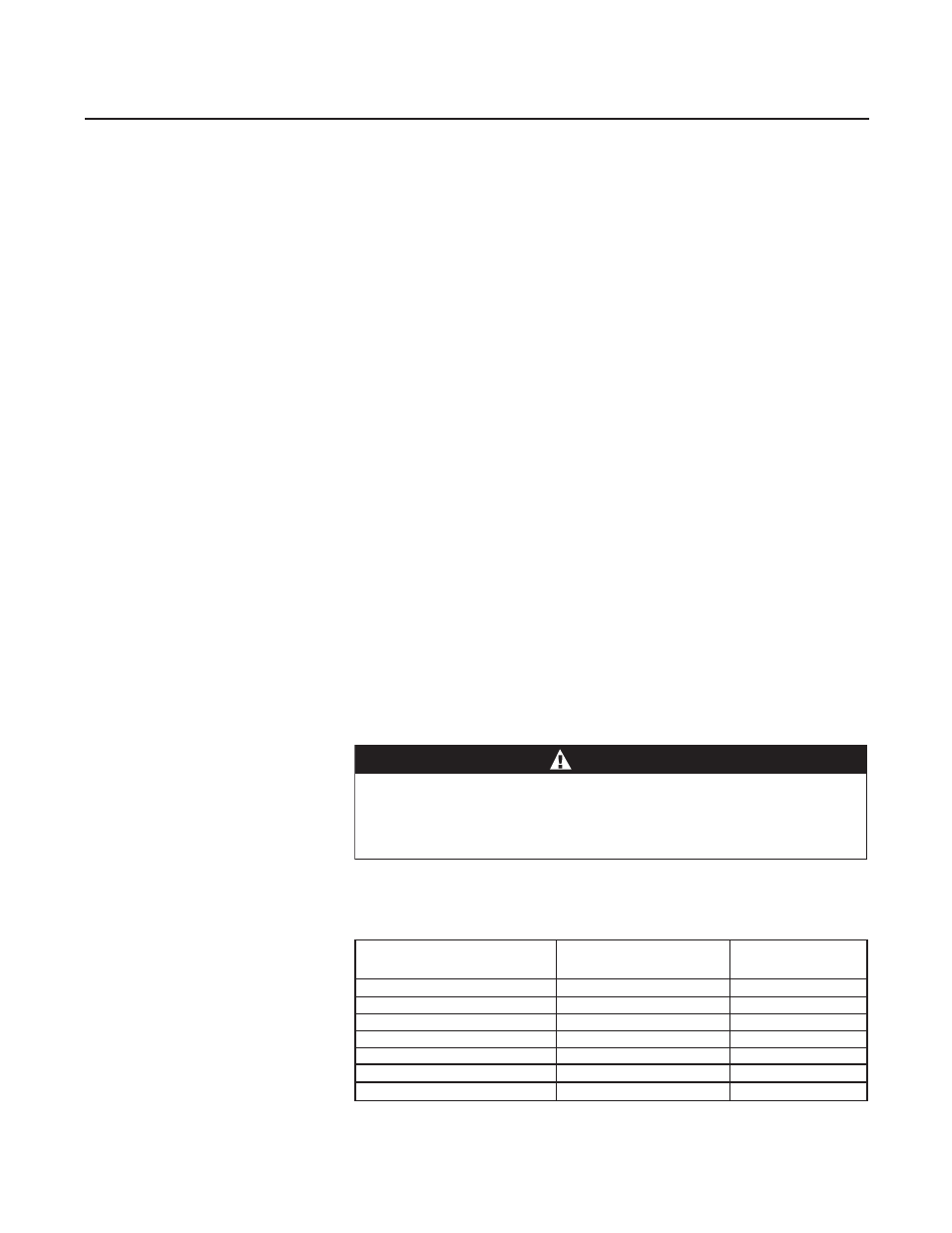

Table 4-5 Restrictor Selection Guide

Example:

The desired gas is Silane (SiH4)

The desired full scale flow rate is 200 sccm.

Sensor conversion factor is 0.625 from Table 4-3.

Nitrogen equivalent flow = 200/0.625 = 320 sccm Nitrogen

In the example above, the restrictor should be sized for a 320 sccm flow

rate.

If a restrictor assembly is being replaced because the original has become

contaminated, the original may be used as a guide to select the

replacement assembly. The porosity of the original element or elements is

marked on the calibration sheet which was shipped with the flow controller.

The replacement assembly should be replaced in the same orientation as

the original restrictor.

Assembly Procedure

1. Select the proper restrictor element combination.

2. When handling restrictor elements use care to insure that they are not

contaminated with dirt, grease, oil, etc. The use of rubber gloves is

recommended.

3. Put a lightly O-ring onto the header plate. The restrictor assembly can

then be installed in the MFC body (restrictor element(s) go in first). It is

important that the restrictor assembly is put into the body in the correct

orientation (Refer to Figure 4-6). Push this assembly in with your

fingers. Do not use an arbor press or hammer to install the restrictor

assembly. The restrictor assembly should be pushed in until it bottoms

out. Do not force it beyond this point.

4. Place the end block O-ring in position and install the end block with the

4 hex socket screws. Tighten these screws to 49 inch-lbs. Do not over

tighten.

The end block screws (31) and the valve screws (3) are not

interchangeable. The end block screws are stronger and are needed

to achieve the pressure rating. The end block screws are darker in

color and can be attracted by a magnet.

CAUTION

5. Install the inlet adaptor fitting.

Range slpm

Restrictor Element

Part Number

Nitrogen Equivalent Flow*

Combination

4.6 to 15

1-40 micron (1 inch)

S613E604BMT

15 to 26

1-40 micron

S613E636BMT

26 to 42

2-40 micron

S613E523BMT

42 to 60

3-40 micron

S613E526BMT

60 to 79

2-40 micron/1-60 micron

S613E528BMT

79 to 93

1-40 micron/2-60 micron

S613E529BMT

93 to 130**

3-60 micron

S613E527BMT

*Based on 0°C Standard Reference Temperature

**For Hydrogen from 130 slpm to 200 slpm use 3-60 micron restrictor elements.

Note: If the air equivalent flow is between two sizes, choose the larger size.