Brooks, Model 5851e – Brooks Instrument 5851E User Manual

Page 23

3-3

Brooks

®

Model 5851E

Section 3 Operation

Installation and Operation Manual

X-TMF-5851E-MFC-eng

Part Number: 541B104AAG

November, 2008

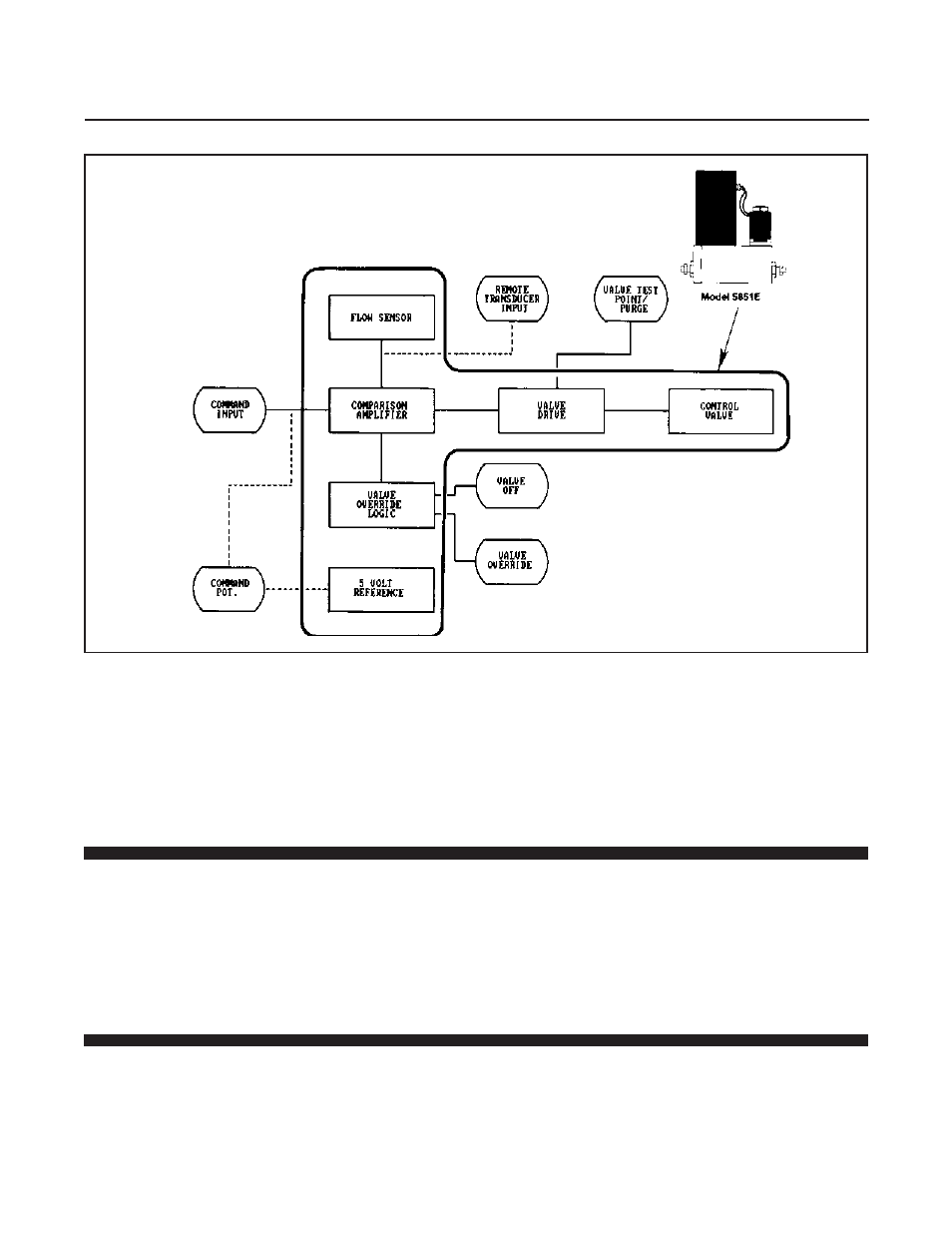

Figure 3-2 Flow Control System Block Diagram

• Remote Transducer Input

Accessed via Terminal 5 on the Card Edge or Pin 15 on the D-Connector

version. This feature allows the use of the integral control electronics and

valve with the signal from an external 0-5 Vdc signal. The mass flow signal

from the Model 5851E is still available for process monitoring. This function

is jumper selectable. Refer to Section 2-9.

3-2 Operating Procedure

a. Apply power to the controller and allow approximately 45 minutes for

the instrument to warm-up and stabilize its temperature.

b. Turn on the gas supply.

c. Command 0% flow and observe the controllers output signal. If the

output is not 0 mVdc (±10 mVdc), check for leaks and if none are found

refer to the zero adjustment procedure in Section 3-3.

d. Set the command for the desired flow rate to assume normal operation.

3-3 Zero Adjustment

Each Model 5851E is factory adjusted to provide a 0 ±10 mVdc signal at

zero flow. The adjustment is made in our calibration laboratory which is

temperature controlled to 21.1°C (70°F ±2°F). After initial installation and

warm-up in the gas system the zero flow indication may be other than the

factory setting. This is primarily caused by changes in temperature

between our calibration laboratory and the final installation. The zero flow

reading can also be affected to a small degree by changes in line pressure

and mounting attitude.