Brooks, Model 5851e – Brooks Instrument 5851E User Manual

Page 28

3-8

Brooks

®

Model 5851E

Section 3 Operation

Installation and Operation Manual

X-TMF-5851E-MFC-eng

Part Number: 541B104AAG

November, 2008

Adjust the span potentiometer until the voltage at TP1 is equal to the value

calculated above. Recheck the flow rate after the flow is stable (at least

2 minutes). Repeat this check and adjustment procedure until the

measured flow rate is within 1% of the desired flow rate.

Note: The voltage at TPl is -100 times the output voltage of the sensor.

This voltage can range from -1.2 to -12 Volts, however it is recom-

mended that this voltage stays between -2.0 and -9.0 Volts for proper

operation. If the recommended voltage range exceeds the desired

accuracy signal stability may not be achieved. If one of the limits is

reached check the orifice and restrictor sizing procedures. Refer to

Sections 4-6 and 4-7 respectively.

g. Set the command potentiometer for 0% of flow. Connect the DVM

positive lead to flow signal output (Terminal 3 Card Edge, Pin 2

D-Connector) and the negative lead to TP4. Readjust the zero potenti-

ometer for an output of 0 mV ±2 mV as necessary.

h. Set the command potentiometer for 50% of flow (2.500 V) and measure

the flow rate. Calculate the error as a percentage of full scale.

Measured

-

Desired Flow

Flow Rate

Rate

Full Scale Error = 100% x

Full Scale Flow Rate

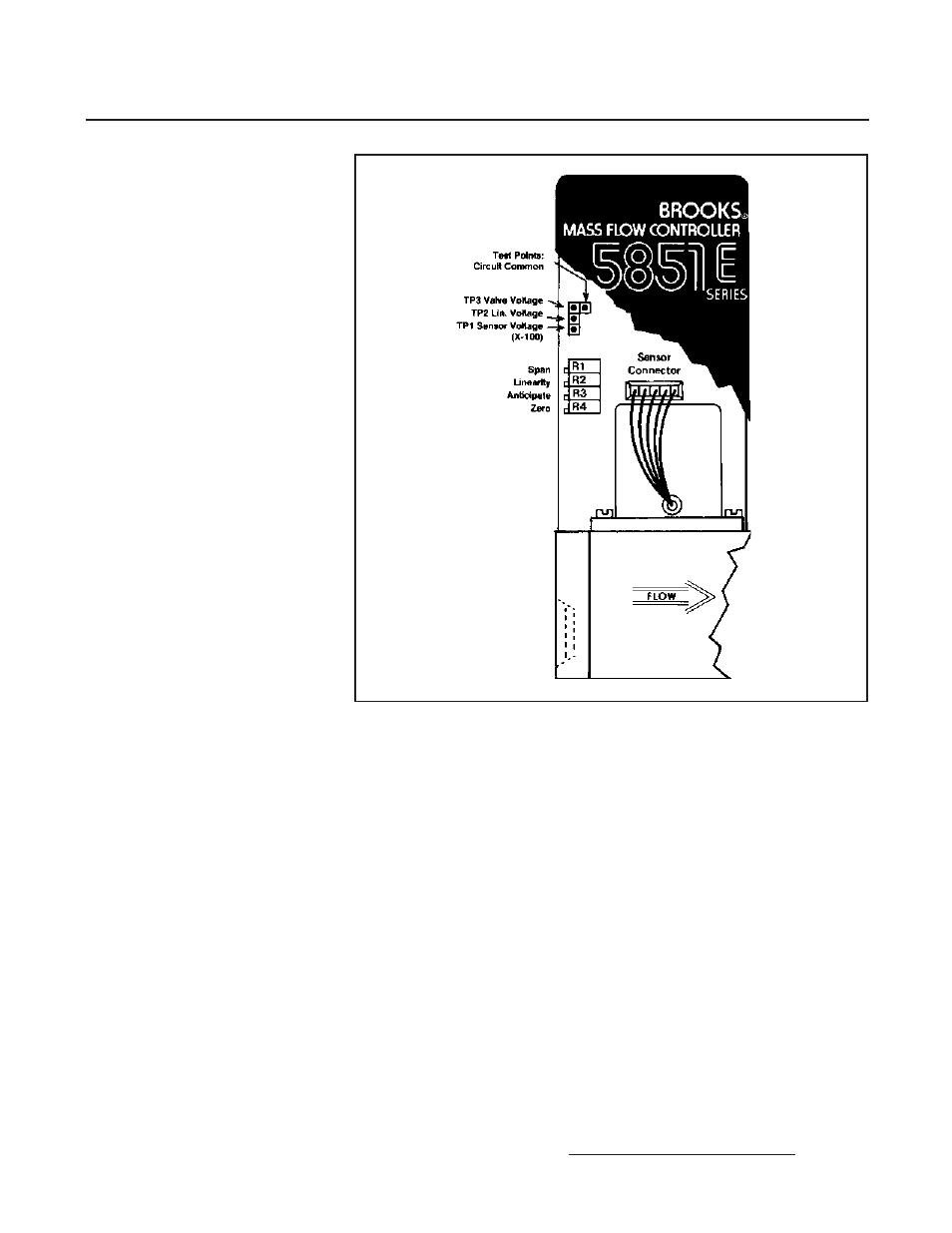

Figure 3-6 Adjustment Potentiometer Location

TP4