Brooks, Model sla5840 – Brooks Instrument SLA5840 User Manual

Page 15

2-3

Brooks

®

Model SLA5840

Section 2 Installation

Installation and Operation Manual

X-PR-SLA5800-RT-eng

Part Number: 541B120AAG

August, 2009

Recommended installation procedures:

a. The Delta Class EL Series RT should be located in a clean, dry atmo-

sphere relatively free from shock and vibration.

b. Leave sufficient room for access to Self-zero function push-button.

c. Install in such a manner that permits easy removal if the instrument

requires servicing.

d. The Delta Class EL Series RT can be installed in any position. How-

ever, mounting in orientations other than the original factory calibration

(see calibration data sheet supplied with the instrument) can result in a

<±0.5% maximum full scale shift after re-zeroing.

e. When installing a mass flow controller or meter with full scale flow rates

of 10 slpm or greater, be aware that sharp, abrupt angles in the system

piping directly upstream of the controller may cause a small shift in

accuracy. If possible, have at least ten pipe diameters of straight tubing

upstream of the mass flow controller or meter. This is not required for

meters with an integrated filter.

2-8 In-Line Filter

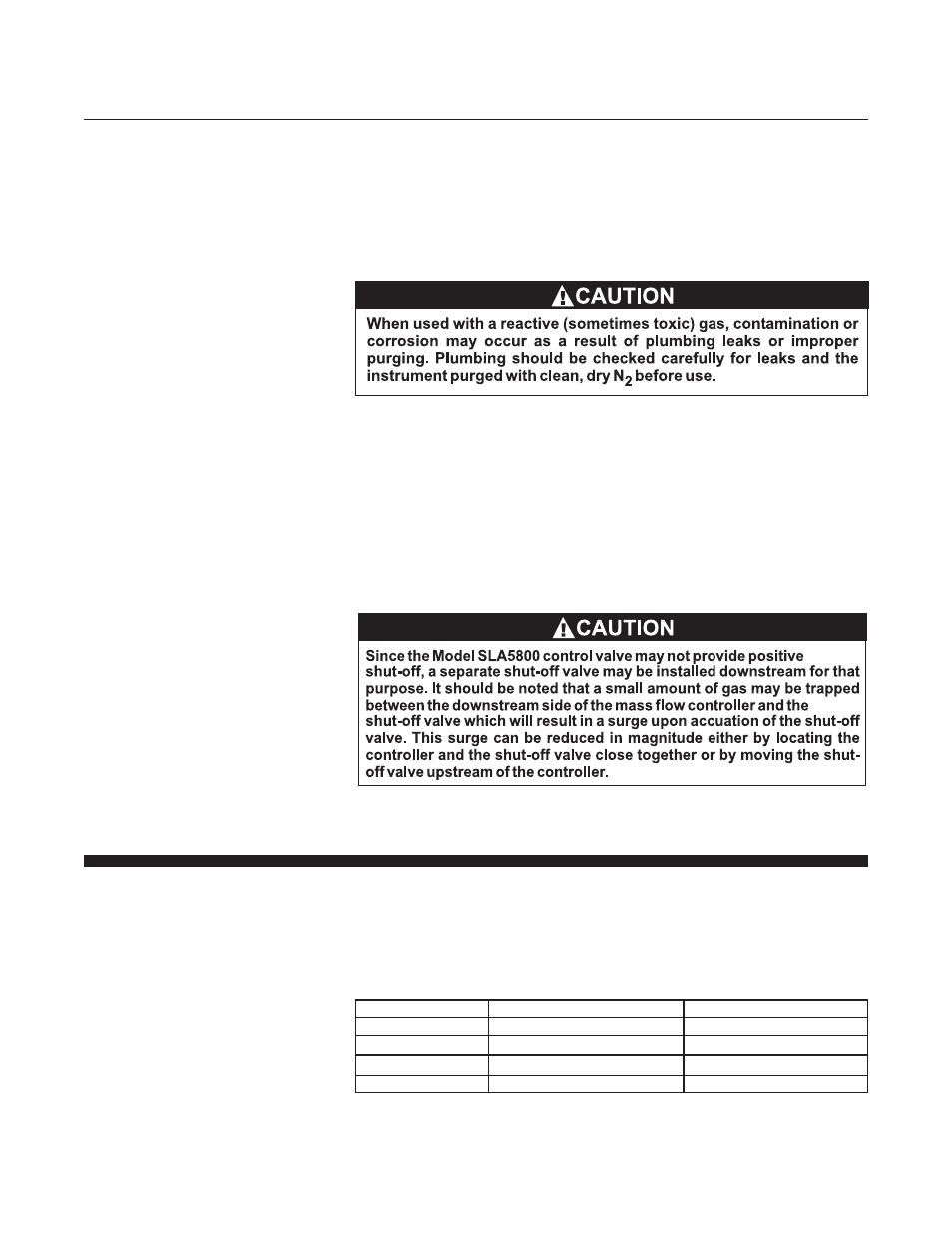

It is recommended that an in-line filter be installed upstream from the mass

flow controller or meter to prevent the possibility of any foreign material

entering the flow sensor or control valve. The filtering element should be

replaced periodically or ultrasonically cleaned.

Table 2-1 Recommended Filter Size

Models

Maximum Flow Rate

Recommended Filter

SLA5840

100 ccm

2 micron

SLA5840

500 ccm

2 micron

SLA5840

1 to 5 lpm

10 micron

SLA5840

10 to 100 lpm

40 micron