Refrigeration system re-processing – ClimaCool IOM FLEX SERIES User Manual

Page 38

www.climacoolcorp.com

www.climacoolcorp.com

®

36

and sustained for several hours in order for the system to

be considered free from moisture. It is necessary to use a

micron meter equipped with an absolute pressure gauge (or

transducer) to take this reading. ClimaCool recommends

the double evacuation process to ensure the proper removal

of moisture and contaminants from the refrigeration system.

After the initial vacuum is reached and held on the system,

allow dry nitrogen back into the system until the pressure

reaches zero PSIG or slightly higher. Then, repeat the entire

evacuation process described above.

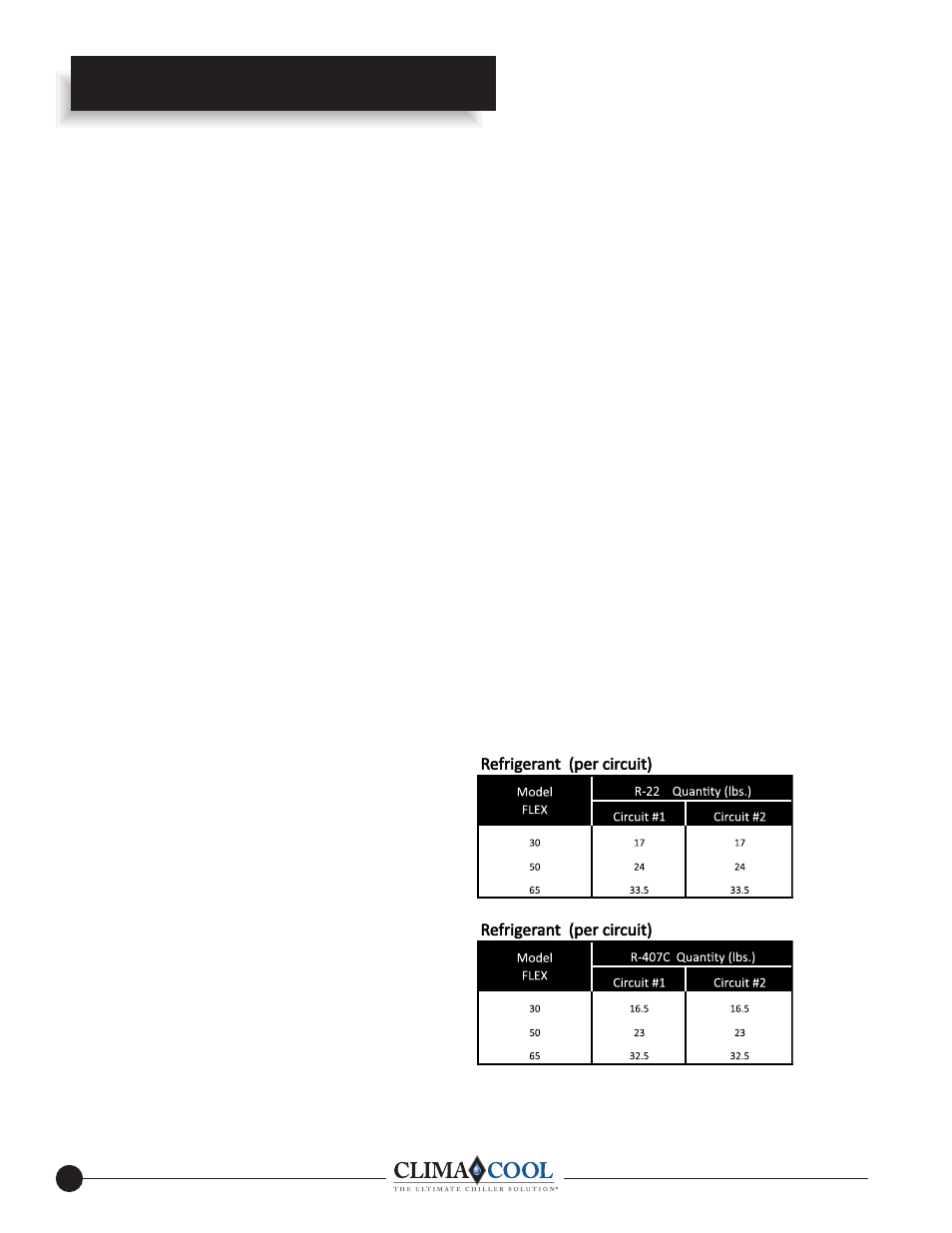

Recharging the System

After all repairs have been completed, the system has been

leak tested, and proper vacuum pressures have been reached

and maintained, refrigerant may be recharged into the system.

With a known weight of refrigerant in the cylinder, use the

gage manifold set to connect the cylinder's liquid charging

port to the charging access port near the refrigerant liquid line

valve. Open the compressor suction and discharge line valves.

Gradually meter the appropriate weight of liquid refrigerant

into the condenser side of the system first, until no additional

refrigerant can be dispensed. Then continue the charging

process by filling the evaporator side of the system with

refrigerant. Close the refrigerant cylinder charging port, close

all gage manifold ports and start the compressor. Be careful

when continuing to charge the balance of the refrigerant,

constantly maintaining a positive compressor suction pressure

(> 25 PSIG) at all times.

Refrigeration System Re-Processing

REFRIGERATION SYSTEM RE-PROCESSING

Conforming to local and national codes is the responsibility

of the service technician or installing contractor. The service

technician should be familiar with the following codes:

ASHRAE Standard Safety Code for Mechanical

Refrigeration, ANSI/ASHRAE 15-1978.

American National Standard Code for Pressure Piping, ANSI

B31.5-1974.

Factory Tested

ClimaCool modular chillers have been leak tested, fully

charged and factory run-tested before shipment. In the

unlikely event that a refrigerant leak is detected at start-

up, the following guidelines should be consulted before

reprocessing the refrigeration systems.

Refrigerant System Reprocessing

Debris and moisture can enter copper tubing in a matter of

minutes. All tubing, coil connections, or any refrigerant

containing portions should be temporarily capped or sealed

to keep contaminants to a minimum. Filter driers should

be opened just prior to brazing into the system to prevent

moisture infiltration whenever possible.

After all of the repairs have been made to the refrigeration

system, a pressure test using refrigerant and dry nitrogen

should be taken. Connect the refrigerant cylinder to the

charging port of the condenser liquid stop valve and bleed

in enough gas to raise the system pressure up to 25 PSI. If

no obvious leaks are present you may proceed. Using a dry

nitrogen supply tank equipped with a pressure regulator set at

150 PSI, continue to raise the pressure up to 150 PSI. Using

a leak detector, carefully check the system for any remaining

leaks. If the system is leak free you may release the pressure.

Evacuating the System

The compressors should never be run while the system is

in a vacuum. This could cause immediate failure to the

compressors. After the system has been leak tested and

sealed, any moisture that entered the system should be

dehydrated and removed. While the pressure is reduced

under a vacuum, the boiling point of moisture trapped

inside the lines is reduced also. A pressure of .0095 PSIA,

or 500 microns absolute pressure or better must be reached

NOTES: Modules are all pre-charged at factory and ready for field

connections. FLEX Modules are refrigerant flexible.