Stainless steel strainer option – ClimaCool IOM FLEX SERIES User Manual

Page 18

www.climacoolcorp.com

www.climacoolcorp.com

®

16

BOLTED LID MODELS: ClimaCool Strainer models CS-

4B, CS-6, CS-8, and CS-10 have "bolted" lid designs. Grade

5 zinc-plated bolts, nuts, and washers are used to attach the

lids to these strainers. See Table 1 for the proper lid bolt

size and torque rating for each strainer. (Exercise care when

tightening the lid bolts so as not to damage the strainer lid or

housing).

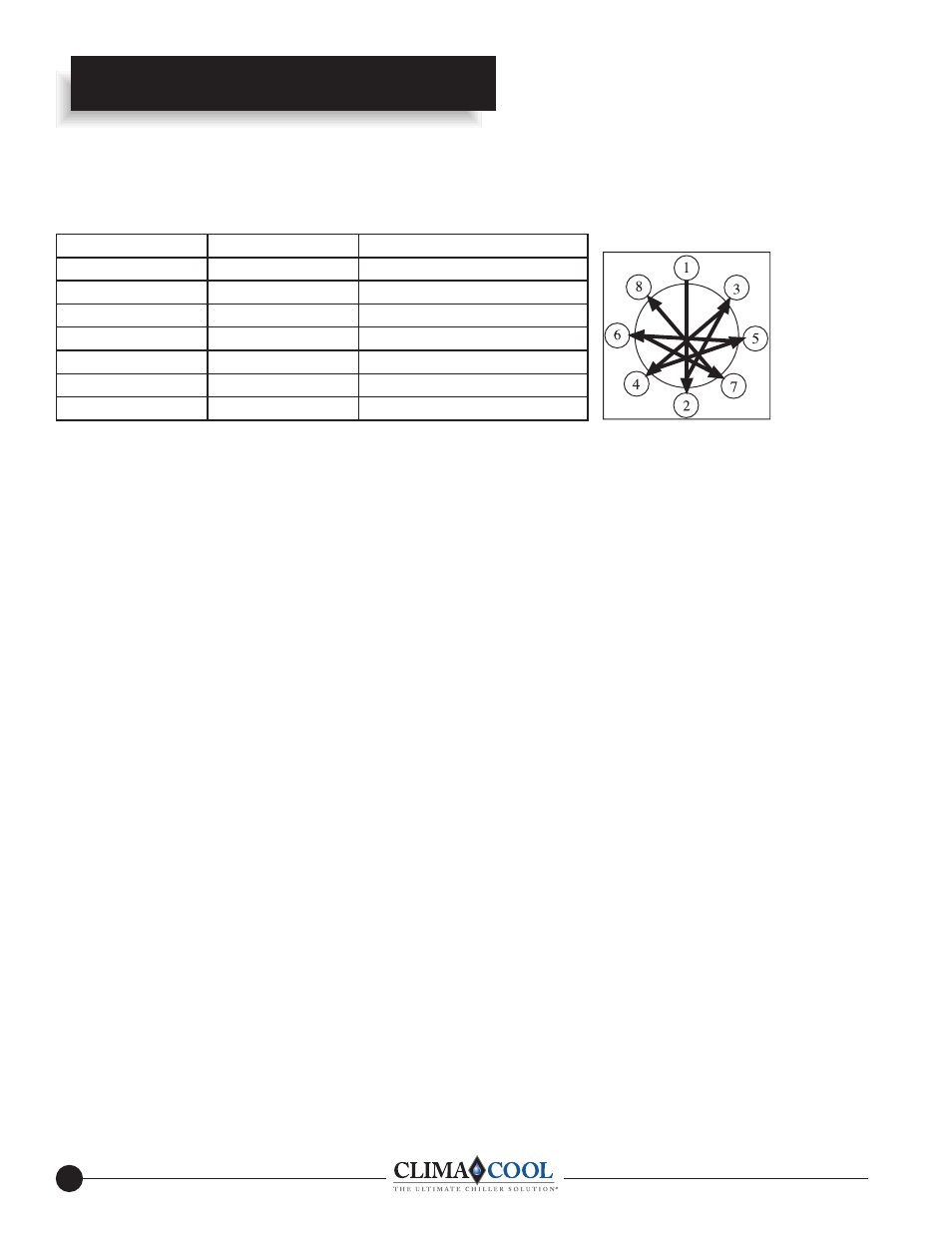

It is important to follow the torque specifications as over-

tightening may result in premature failure of the bolts. It is

equally important to follow a star wheel torque pattern when

tightening the lid bolts (see Fig. 2). The strainer lid may not

be seated down completely after the first torque sequence

(this is especially evident on the larger strainers such as

the CS-8 and larger). A second torque sequence should be

adequate to seat the lid securely to the body.

Strainer Operation

Periodically, it will be necessary to flush out the debris that

is collected and settles to the bottom of the strainer reservoir.

The larger ClimaCool strainers (CS-4, CS-6, CS-8, and

CS-10) are equipped with a flush port (or drainage port)

extending inside the strainer. When it becomes time to clean

the strainer, the flush port valve should be opened while the

strainer is in operation (while pressurized and with water

flowing). A thorough flushing of the strainer reservoir will

depend upon the length of time the flush valve remains

opened. This flush time will typically range from 15 to 60

seconds depending on the flow, inlet water pressure, and the

amount of debris collected by the strainer. As a general rule,

the larger strainers will require higher inlet water pressures

in order to achieve a complete flushing. For example, the

CS-4 model can be flushed with inlet water pressures as low

as 15 PSI, while the CS-6 can be flushed with 30 PSI. The

CS-8 and CS-10 models should be flushed with inlet water

pressures greater than 40 PSI.

Stainless Steel Strainer Option

Note: When shutting down the chiller for extended periods

of time, the strainer should be isolated and completely

drained.

Strainer Element Cleaning

If your strainer assembly is equipped with optional pressure

gauges, you will be able to monitor the pressure differential

between the inlet and outlet sides of the strainer. Under a

normal "clean" strainer operation this pressure difference

should be slightly under 1 PSI. When this pressure

differential reaches 5-10 PSI, the strainer element may

require cleaning.

CAUTION: PRIOR TO DISMANTLING THE

STRAINER FOR CLEANING, IT IS IMPERATIVE

THAT THE STRAINER ASSEMBLY IS ISOLATED

AND COMPLETELY DE-PRESSURIZED.

Follow these steps when cleaning the ClimaCool Strainer

element:

Step 1 (Bolted Lid Models): Remove the top of the

ClimaCool Strainer by removing the Grade 5 Zinc plated

bolts from the lid.

Step 1 (Band-Clamp Lid Models): Remove the top of the

ClimaCool Strainer by taking off the band-clamp assembly.

Step 2: Lift the strainer element (conical screen) out of the

strainer body.

Step 3: Carefully scrub down the strainer element with a

rigid nylon brush until all matter is loosened. DO NOT USE

STEEL BRUSH

Step 4: Wash the strainer element off with clean water. It

STRAINER

BOLT SIZE

RECOMMENDED TORQUE

CS-2 (Clamp)

5/16 - 18

40 - 50 in. lbs.

CS-3 (Clamp)

5/16 - 18

60 - 80 in. lbs.

CS-4C (Clamp)

5/16 - 18

75 - 85 in. lbs.

CS-4B

3/8 -16

15 - 25 ft. lbs.

CS-6

1/2 - 13

45 - 55 ft. lbs.

CS-8

1/2 - 13

45 - 55 ft. lbs.

CS-10

5/8 - 11

80 - 100 ft. lbs.

Fig. 2 - Recommended

Torquing Sequence

Table 1