Caution, Climacool, Application parameters – ClimaCool IOM FLEX SERIES User Manual

Page 15

www.climacoolcorp.com

®

13

WATER TREATMENT

Proper water treatment is a specialized industry. We

recommend consulting an expert in this field to analyze

the water for compliance with the water quality parameters

listed in Table 1 below. The material used in the ClimaCool

chiller exposed to the water are type 316 stainless steel,

pure copper, and carbon steel. Other materials may

exist external to the ClimaCool

chiller. It is the users

responsibility to ensure these materials are compatible with

the treated water. Failure to provide proper water quality

will void the ClimaCool module's warranty.

It is further recommended to seek an experts advice to

specify the appropriate water treatment required. Typical

additives to hydronic systems include rust inhibitors,

scaling preventative, antimicrobial growth agents, and algae

preventatives. Anti-freeze solutions may also be used to

lower the freezing point.

Heavily-Contaminated Water

In such instances whereby the particulates in the water are

excessive it is recommended to install an intermediate plate

& frame heat exchanger to isolate the ClimaCool

chiller

from the building water system.

Water Treatment

Other Considerations

The following considerations are listed to help achieve

system longevity.

Cooling Tower

The cooling tower should be located away from sources of

external contaminates such as trees, dust, or grass cuttings.

Insect infiltration can be reduced by eliminating lights near

the tower. A periodic visual inspection of the tower system

should be made and contaminates removed as required.

Table 1 - Water Quality Parameters

11

Water Flow Rates

It is imperative that minimum and maximum water fl ow

rates are not exceeded. Minimum and maximum water fl ow

rates are defi ned in the Physical Data tables of this manual.

o

t

d

e

ri

u

q

e

r

si

h

ct

i

w

s

e

r

u

s

s

e

r

p

l

ai

t

n

e

r

e

ff

i

d

r

o

h

ct

i

w

s

w

o

fl

A

confi rm fl ow in the chilled water and condenser circuits.

Chilled Water Temperature Limits

ClimaCool

®

FLEX Series

FLEX

FLEX Series modules are designed for a leav-

5

o

t

F

˚

0

4

m

o

rf

e

g

n

a

r

e

r

u

t

a

r

e

p

m

et

r

et

a

w

g

n

i

5

˚F. All cata-

loged modules can operate safely in this range without the

need of special controls or glycol additives. Leaving water

temperatures below 40˚F can result in evaporator suction

temperatures below the freezing point of water. Therefore,

we require a glycol solution additive that will protect the

evaporator from freeze ups at lower operating suction tem-

peratures. The full range of leaving chiller fl uid using glycol

is 20˚F to 55˚F on the Flex Series.

Condenser Water Temperature

The condensers are designed to operate most effi ciently at

lower entering water temperatures for lower power con-

sumption. Operating lower than a recommended 60˚F will

.

e

c

n

a

m

r

o

f r

e

p

m

et

s

y

s

tc

e

ff

a

y

le

sr

e

v

d

a

d

n

a

y

c

n

ei

c

fi

f

e

et

a

g

e

n

The full range of entering condenser water is 60˚F to 105˚F.

Water Quality Parameters

Water Piping Practices

As with any water system, it is important that the system be

clean. If care is taken during installation, the possibility of

dirt related problems are avoided in future operation of the

chiller. The pipe work installer must remove weld scale, rust

and contamination during pipe work fabrication.

There are certain necessary components that should always

be installed in both the chilled water and condenser water

systems (see Water Piping Confi gurations on page 24 in this

manual.) Isolation valves are required in the position shown

to isolate the chiller for maintenance and also to allow iso-

a

d

n

a

el

b

a

ri

s

e

d

o

sl

a

si

t

I

.

g

n

i

n

a

el

c

r

o

f

sr

e

n

ia

rt

s

e

h

t

f

o

n

o

it

al

.

s

p

m

u

p

e

h

t

g

n

i t

al

o

si

s

e

v

la

v

e

v

a

h

o

t

e

ci

tc

a

r

p

d

o

o

g

Refer to the ClimaCool

®

modular chiller water piping

-

u

g

fi

n

o

c

g

n

i

p

i

p

r

o

f

)

4

2

e

g

a

p

n

o

2

d

n

a

1

.

s

g

i

F

(

s

n

o

it

a

r

u

g

fi

n

o

c

s

n

o

it

c

e

n

n

o

c

g

n

i

p

i

p

l

a

n

fi

e

r

o

f

e

B

.

s

el

u

d

o

m

e

l

p

it

l

u

m

n

o

s

n

o

it

a

r

are made to the chiller, all external water piping must be

thoroughly fl ushed. Suffi cient insulation should be installed

.

n

ia

g

t

a

e

h

e

c

u

d

e

r

d

n

a

n

o

it

a

s

n

e

d

n

o

c

t

n

e

v

e

r

p

o

t

d

el

a

e

s

d

n

a

Chilled water volume can be accommodated with the

.s

k

n

at

n

o

is

n

a

p

x

e

f

o

e

s

u

ClimaCool

®

Strainer

ClimaCool

®

requires quality strainers with a minimum

of 60 mesh strainer screen to protect the chilled and con-

l

o

o

C

a

m

i

l

C

e

h

T

.

m

et

s

y

s

e

h

t

f

o

s

e

d

is

r

et

a

w

r

e

s

n

e

d

®

Strainer

Package (listed on page 8, Optional Features) meets all

requirements and offers the convenience of an optional

automatic fl ush timer and a high pressure alarm. "Y" and

Basket Strainers are also available (listed on page 9, Optional

Features). Installation of a strainer will:

• Increase effi ciency

• Reduce abrasion and wear

• Ensure longer equipment life

• Provide greater return on your investment

• Filtration enhances the action of your water

treatment program

For more information on the ClimaCool

®

strainer, consult

l

o

o

C

a

m

i

l

C

d

e

zi

r

o

h

t

u

a

la

c

o

l

r

u

o

y

®

representative.

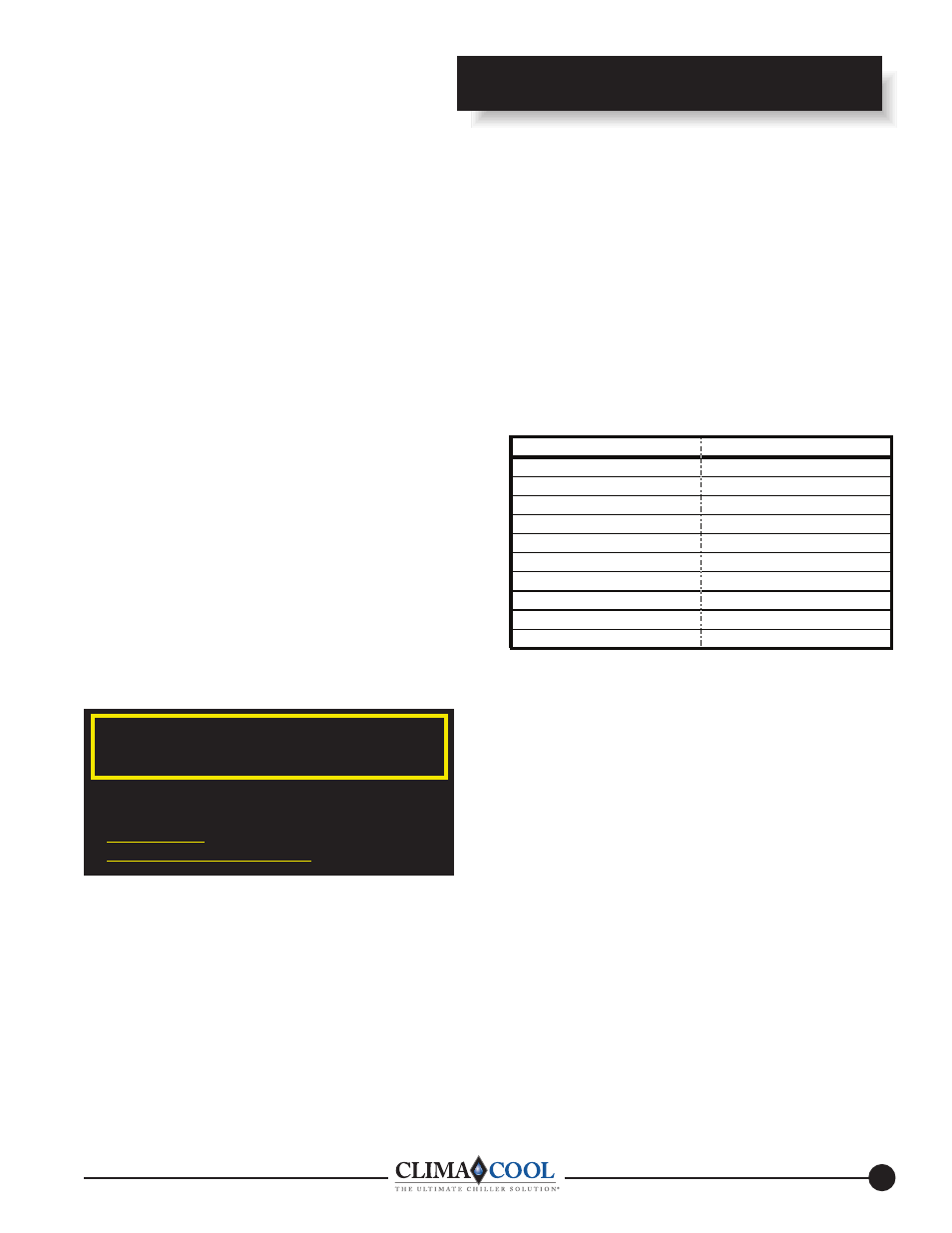

Table 1 - Water Quality Parameters

WATER CONTAINING

CONCENTRATION

Sulphate

Less Than 200 ppm

pH

7.0 – 9.0

Chlorides

Less Than 200 ppm

Nitrate

Less Than 100 ppm

Iron

Less Than 4.5 mg/l

Ammonia

Less Than 2.0 mg/l

Manganese

Less Than 0.1 mg/l

Dissolved Solids

Less Than 1000 mg/l

CaCO3 Hardness

30 – 500 ppm

CaCO3 Alkalinity

30 – 500 ppm

ClimaCool

®

Application Parameters

Proper water treatment is a specialized industry. We recom-

mend consulting an expert in this field to analyze the water

for compliance with the water quality parameters listed in

Table 1 below. The material used in the ClimaCool

®

chiller

exposed to the water are type 316 stainless steel, pure

copper, and carbon steel. Other materials may exist external

to the ClimaCool

®

chiller. It is the users responsibility to

ensure these materials are compatible with the treated water.

Failure to provide proper water quality will void the

ClimaCool

®

module's warranty.

It is further recommended to seek an experts advice to

specify the appropriate water treatment required. Typical

additives to hydronic systems include rust inhibitors, scaling

preventative, antimicrobial growth agents, and algae preven-

tatives. Anti-freeze solutions may also be required to lower the

freezing point, based on the application.

Heavily-Contaminated Water

In such instances whereby the particulates in the water are

excessive it is recommended to install an intermediate plate

& frame heat exchanger to isolate the ClimaCool

®

chiller

from the building water system.

www.climacoolcorp.com

CAUTION

• Excessive Chlorine, Undissolved Solids and

other improper water quality conditions

WILL DAMAGE the internal heat exchanger and

WILL VOID YOUR WARRANTY!

• Please refer to the Installation and Operations

Manual for water quality parameters and

maintenance instructions.

For Warranty information, go to www.climacoolcorp.com

95B0051N01