Chiller operation and maintenance, Recommended maintenance schedule – ClimaCool IOM FLEX SERIES User Manual

Page 30

www.climacoolcorp.com

www.climacoolcorp.com

®

28

CHILLER OPERATION AND MAINTENANCE

Pressure and Temperature Log

A log of temperatures and pressures should be taken

regularly. Periodically conduct a visual inspection

of the chiller to identify problems before they reach

the point of failure. As with any mechanical system,

it is necessary to conduct a series of checks to the

ClimaCool chiller to confirm correct operation.

Daily

• A daily operational log should be kept

• Perform visually inspection

• Record entering and leaving chilled water and

condenser water temperatures and pressures

• Note any problems that may exist. Immediately

plan for further investigation. If repair is necessary,

schedule for earliest possible date.

• Properly document all data taken

Weekly

• Review daily log from previous week

• Perform visual inspection

• Properly document all data taken

• Note any problems that may exist. Immediately plan for

further investigation. If repair is necessary, schedule for

earliest possible date.

Quarterly

• Check controller operating parameters and set points

• Check refrigerant pressures and temperatures

• Check compressor amps

• Check compressor oil level

• Check and test all safeties

• Check water flow rates and pressure drops across

evaporator and condenser

• Properly document all data taken

Annual

• Isolate chiller, drain all water circuits

• Back flush all heat exchangers (use only ClimaCool

recommended de-scalers)

• Remove and clean all waterside strainers

• Perform leak test on all refrigerant circuits

• Check all interconnecting flanges for proper

tightness

• Perform oil analysis on each compressor

• Check and test all refrigerant safeties for proper operation

• Check all electrical terminal connections for tightness

• Manually operate all waterside isolation valves on each

module

• Check all peripheral systems for proper operation

• Check and test main controller

• Verify set points, sensors and general configuration

• Properly document all data taken

HEAT EXCHANGERS

Back Washing

It may become evident from the recorded daily log data that

the performance of the chiller is gradually degrading. This

could be due to a buildup of debris or sludge obstructing the

free passage of flow through the heat exchangers. This debris

can be removed by a "back washing" process, which involves

the introduction of a forced, violent, backwards flow through

the heat exchanger, using a carefully formulated flushing

solution. To be effective, this back flow should be slightly

Chiller Operation and Maintenance

1

www.climacoolcorp.com

Recommended Maintenance Schedule

Pressure and Temperature Log

A log of temperatures and pressures should be taken regularly. Periodically conduct a visual inspection of the chiller to

identify problems before they reach the point of failure. As with any mechanical system, it is necessary to conduct a

series of checks to the ClimaCool

®

chiller to confirm correct operation.

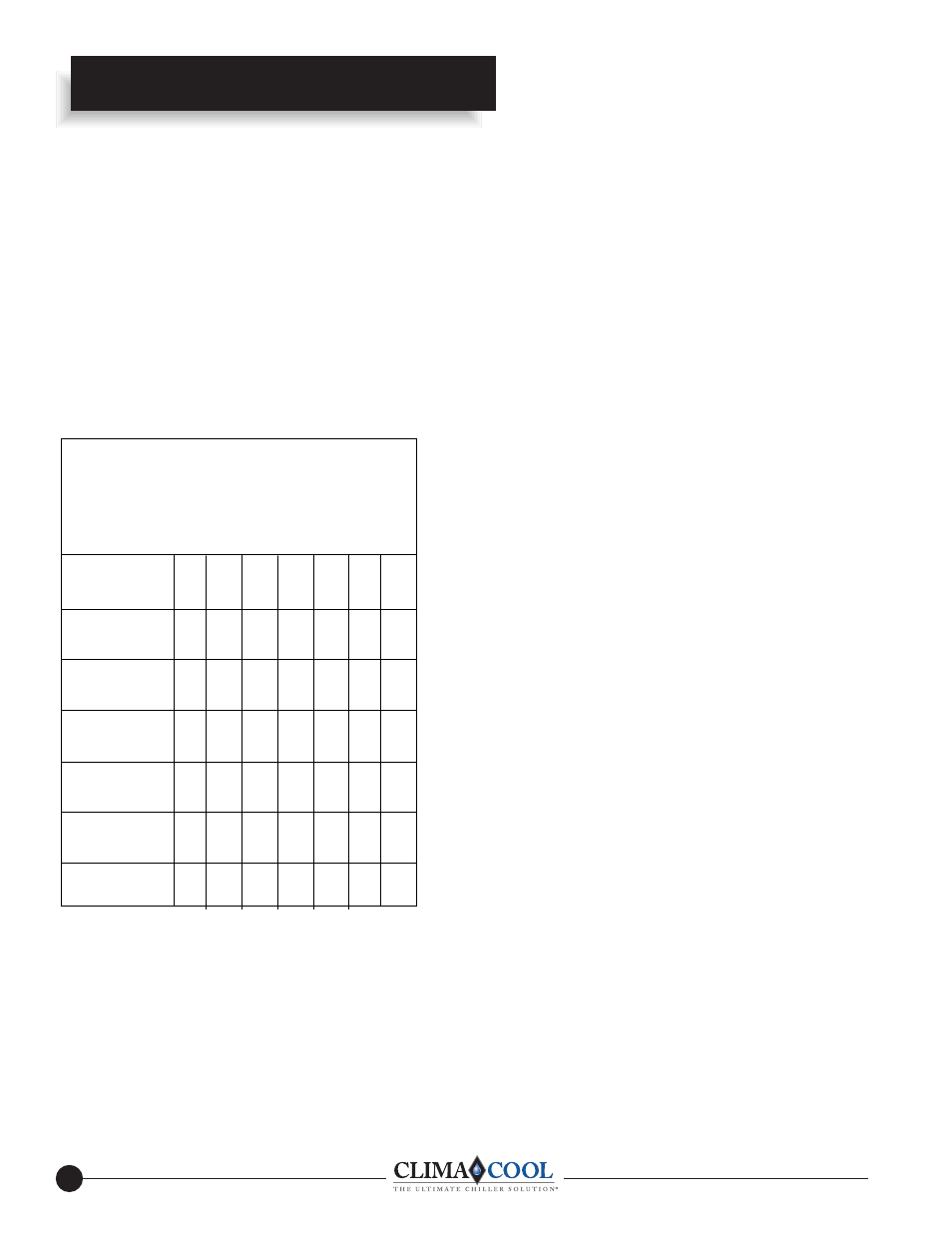

Maintaining a Daily Log

Date _______

Data Log ___________________

Chiller No.

______

Technician

___________________

Sun. Mon. Tue. Wed. Thu. Fri. Sat.

Chilled Water

Entering Temp.

Chilled Water

Leaving Temp.

Condenser Water

Entering Temp.

Condenser Water

Leaving Temp.

Chilled Water

Pressure Drop

Condenser Water

Pressure Drop

Faults: Note By

Module Number

Daily

•

A daily operational log should be kept

•

Perform visually inspection

•

Record entering and leaving chilled water and

condenser water temperatures and pressures

•

Note any problems that may exist. Immediately

plan for further investigation. If repair is

necessary, schedule for earliest possible date.

•

Properly document all data taken

Weekly

•

Review daily log from previous week

•

Perform visual inspection

•

Properly document all data taken

•

Note any problems that may exist.

Immediately plan for further investigation. If

repair is necessary, schedule for earliest

possible date.

Quarterly

•

Check controller operating parameters and set

points

•

Check refrigerant pressures and temperatures

•

Check compressor amps

•

Check compressor oil level

•

Check and test all safeties

•

Check water flow rates and pressure drops

across evaporator and condenser

•

Properly document all data taken

Annual

•

Isolate chiller, drain all water circuits

•

Back flush all heat exchangers (use only

ClimaCool

®

recommended de-scalers)

•

Remove and clean all waterside strainers

•

Perform leak test on all refrigerant circuits

•

Check all interconnecting flanges for

proper tightness

•

Perform oil analysis on each compressor

•

Check and test all refrigerant safeties for

proper operation

•

Check all electrical terminal connections for

tightness

•

Manually operate all waterside isolation valves

on each module

•

Check all peripheral systems for proper

operation

•

Check and test main controller

•

Verify set points, sensors and general

configuration

•

Properly document all data taken