Troubleshooting guide – ClimaCool UCW_H 30, 50, 70, 85 User Manual

Page 61

59

www.climacoolcorp.com

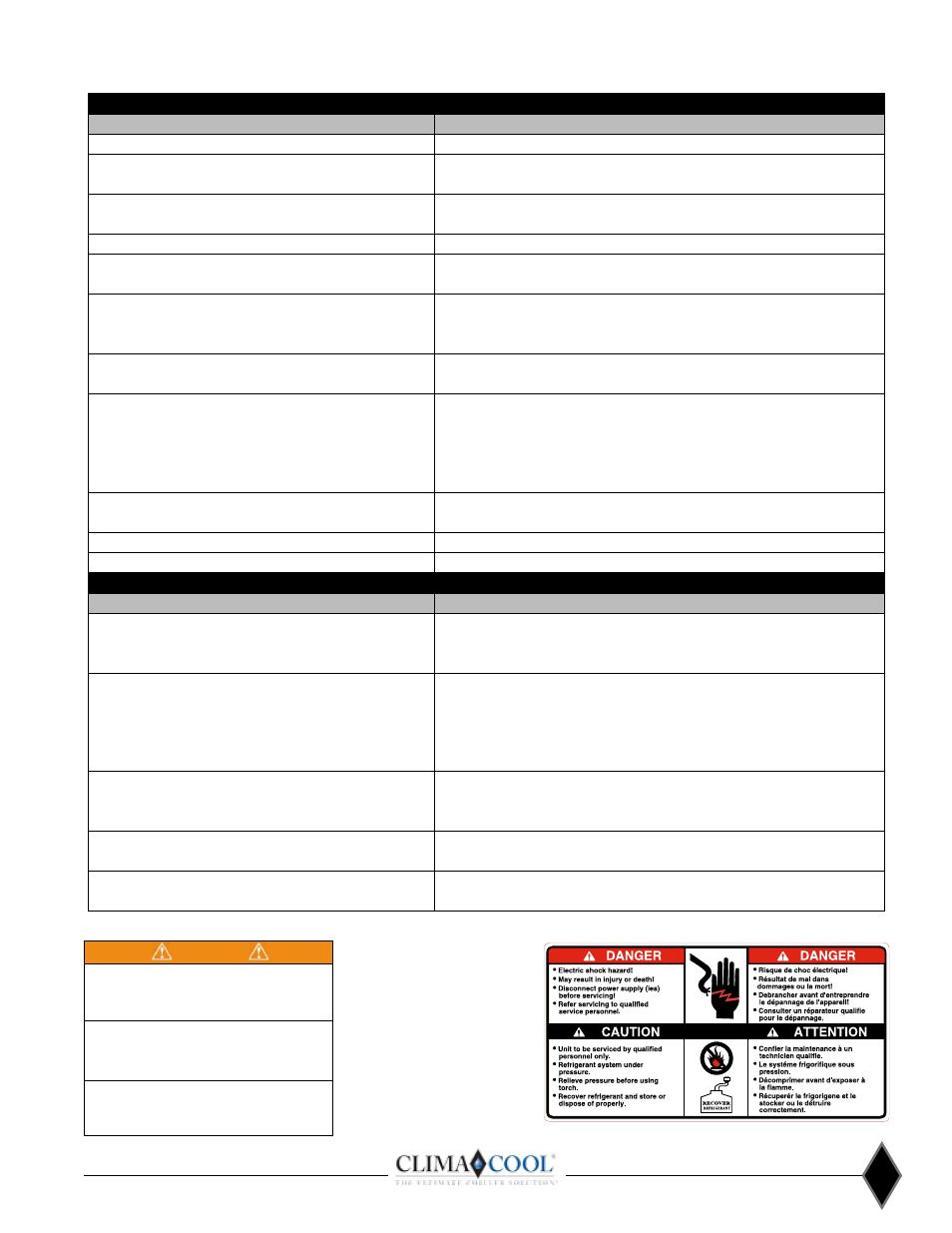

Troubleshooting Guide

Compressor Cycle On High Pressure Control

Possible Cause

Remedy

Main condenser water valve closed or restricted

Open valve to full open position.

Module condenser water isolation valves, if

provided, closed or restricted

Open valves to full open position.

Water regulating valve incorrectly set or

defective

Reset or replace.

Compressor discharge valve partially closed

Open valve to full open position.

Non-condensable gases in hydronic system

Recover non-condensable gases from bleed valve on condenser

or at bleed valve of the building condenser water system.

Overcharge of refrigeration

Recover refrigerant from system while in operation until the first

sign of bubbles are shown in the sight glass. Add back

refrigerant just until bubbles clear.

Condenser water temperature high

Check water supply temperature against requirements; if

cooling tower is used check spray nozzles on cooling tower.

Improper condenser water circulation

Use an ample sized cleanable strainer in the condenser water

circuit; make certain the strainer is clean to insure full flow of

condenser water (strainer must be 60 mesh minimum). It may

sometimes be necessary to treat water to prevent formation of

deposits.

Insufficient water flow through the condenser

Check water flow through condenser against design

requirements.

Fouled condenser brazed plate heat exchanger

Clean-in-place heat exchanger as described in IOM (page 31).

Defective high pressure switch

Replace high pressure switch.

Causes and Prevention of Freeze-Ups

Possible Cause

Remedy

Improper charging

Charge per ClimaCool data plate information, located on the

chiller, following the Superheat and Subcooling procedure

described in IOM (page 25).

Improper chilled water circulation

Use an ample sized cleanable strainer in the chilled water circuit;

make certain the strainer is clean to insure full flow and velocity

of chilled water (strainer screen must be 60 mesh minimum). It

may sometimes be necessary to treat water to prevent

formation of deposits.

Not draining for winter shutdown

When the system is shut down for the winter, remove the drain

plugs from the flush ports

and drain the cooler. Blow out remaining water with air.

Faulty leaving chilled solution temperature

Verify sensor calibration using a calibrated thermometer and

replace if defective.

Wrong freeze-up protection temperature

setpoint

Verify leaving chilled solution freeze protection temperature

setpoint to be set at 8

o

F above solution freeze point.

WARNING

To avoid the release of refrigerant into the atmosphere,

the refrigerant circuit of this unit must be serviced only by

technicians who meet local, state and federal proficiency

requirements.

All refrigerant discharged from this unit must be recovered

WITHOUT EXCEPTION. Technicians must follow industry

accepted guidelines and all local, state and federal statutes for

the recovery and disposal of refrigerants.

If a compressor is removed from this unit, system refrigerant

circuit oil will remain in the compressor. To avoid leakage of

compressor oil, the refrigerant lines of the compressor must

be sealed after it is removed.

Note: See page 43 for Troubleshooting for Stainless Steel Strainer ATF Package.