Chiller operation and maintenance, Annual, Pressure and temperature log – ClimaCool UCW_H 30, 50, 70, 85 User Manual

Page 32: Maintaining a daily log, Daily, Weekly, Quarterly

www.climacoolcorp.com

30

• Check water flow rates and pressure drops across

evaporator and condenser heat exchangers .

• Properly document all data taken .

• Check all electrical connections for tightness .

* The temperature drop/rise on a fully loaded (both

compressors) heat exchanger is generally 10°F . If only

one compressor is running the temperature drop/rise

will be approximately 5°F . Some projects are designed to

have a higher or lower temperature drop on either the

evaporator or the condenser depending on application .

Consult the bank performance sheet for your specific

project for these values . If the temperature drop/rise

is greater than the design, your heat exchanger may

need to be back flushed or the strainer may need to

be cleaned .

Annual

• Back flush all heat exchangers. If fouling is

suspected use only ClimaCool recommended

de-scalers (see page 31 – Chemical Clean In

Place Washing) .

• Remove and clean all waterside strainers .

• Manually operate all waterside isolation valves,

if provided, on each module .

• Check all electrical connections for tightness .

• Perform leak check on all refrigerant circuits .

• Check all header piping couplings for tightness .

• Check oil level and color on each compressor .

• Check and test all refrigerant safeties for

proper operation .

• Check all peripheral systems for proper operation .

• Check and test CoolLogic Control System .

• Verify set points, sensors and general control

configuration.

• Properly document all data taken .

Chiller Operation and Maintenance

Pressure and Temperature Log

A log of temperatures and pressures should be taken

regularly . Periodically conduct a visual inspection of the

chiller to identify problems before they reach the point of

failure . As with any mechanical system, it is necessary to

conduct a series of checks to confirm correct operation of

the chiller .

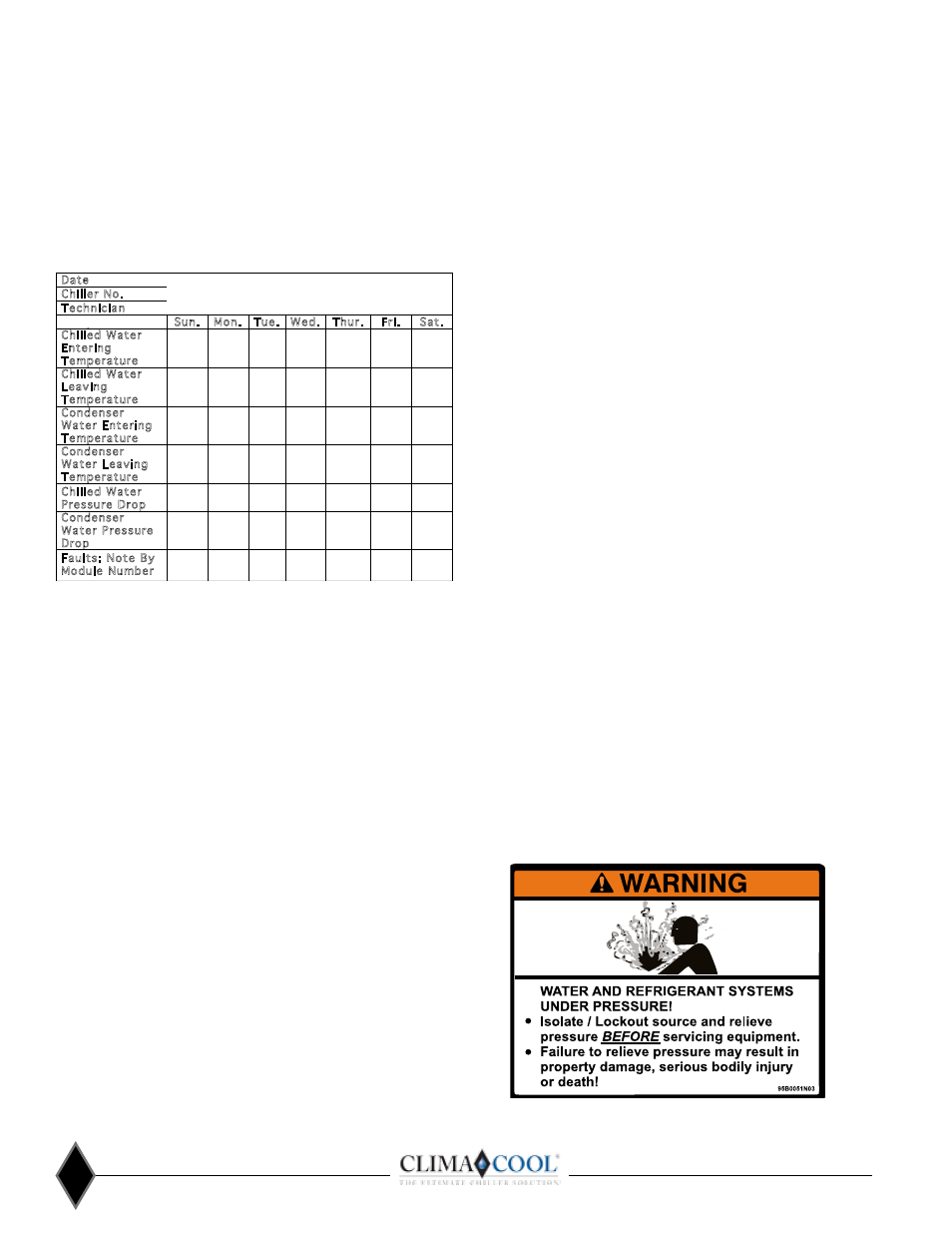

Maintaining a Daily Log

Date

Chiller No.

Technician

Sun. Mon. Tue. Wed. Thur. Fri. Sat.

Chiller Water

Entering

Temperature

Chilled Water

Leaving

Temperature

Condenser

Water Entering

Temperature

Condenser

Water Leaving

Temperature

Chilled Water

Pressure Drop

Condenser

Water Pressure

Drop

Faults: Note By

Module Number

Daily

• A daily operational log should be kept .

• Perform visual inspection .

• Record entering and leaving chiller water and

condenser water temperatures and pressures .

• Properly document all data taken .

• Note any problems that may exist and immediately

plan for further investigation . If repair is

necessary, schedule for the earliest possible date .

Weekly

• Review daily log from previous week .

• Perform visual inspection .

• Properly document all data taken .

• Note any problems that may exist and immediately

plan for further investigation . If repair is necessary,

schedule for the earliest possible date .

Quarterly

• Check Master Control Panel operating parameters

and set points .

• Check temperature drop/rise on each individual

heat exchanger . *

• Check compressor oil level .

• Check compressor oil color .

Date

Chiller No.

Technician

Sun. Mon. Tue. Wed. Thur. Fri. Sat.

Chiller Water

Entering

Temperature

Chilled Water

Leaving

Temperature

Condenser

Water Entering

Temperature

Condenser

Water Leaving

Temperature

Chilled Water

Pressure Drop

Condenser

Water Pressure

Drop

Faults: Note By

Module Number