Caution, Introduction, Attention installer – ClimaCool UCW_H 30, 50, 70, 85 User Manual

Page 3: General description, Safety, Danger, Caution attention

1

www.climacoolcorp.com

Introduction

General Description

ClimaCool’s dedication to energy and environmental

leadership led to the Ultimate Chiller Solution design .

Available in 30, 50, 70 and 85 tons, each module is compact,

redundant, maneuverable, efficient, reliable and serviceable.

Combined tonnages can obtain specific project turndown

and capacity requirements from 30 to 1,000 tons per bank

while having the ability to accommodate future growth and

expansion needs .

The UCW/H model can offer hot gas bypass, heat pump and

heat recovery options utilizing environmentally friendly

R-410A refrigerant for Green building designs .

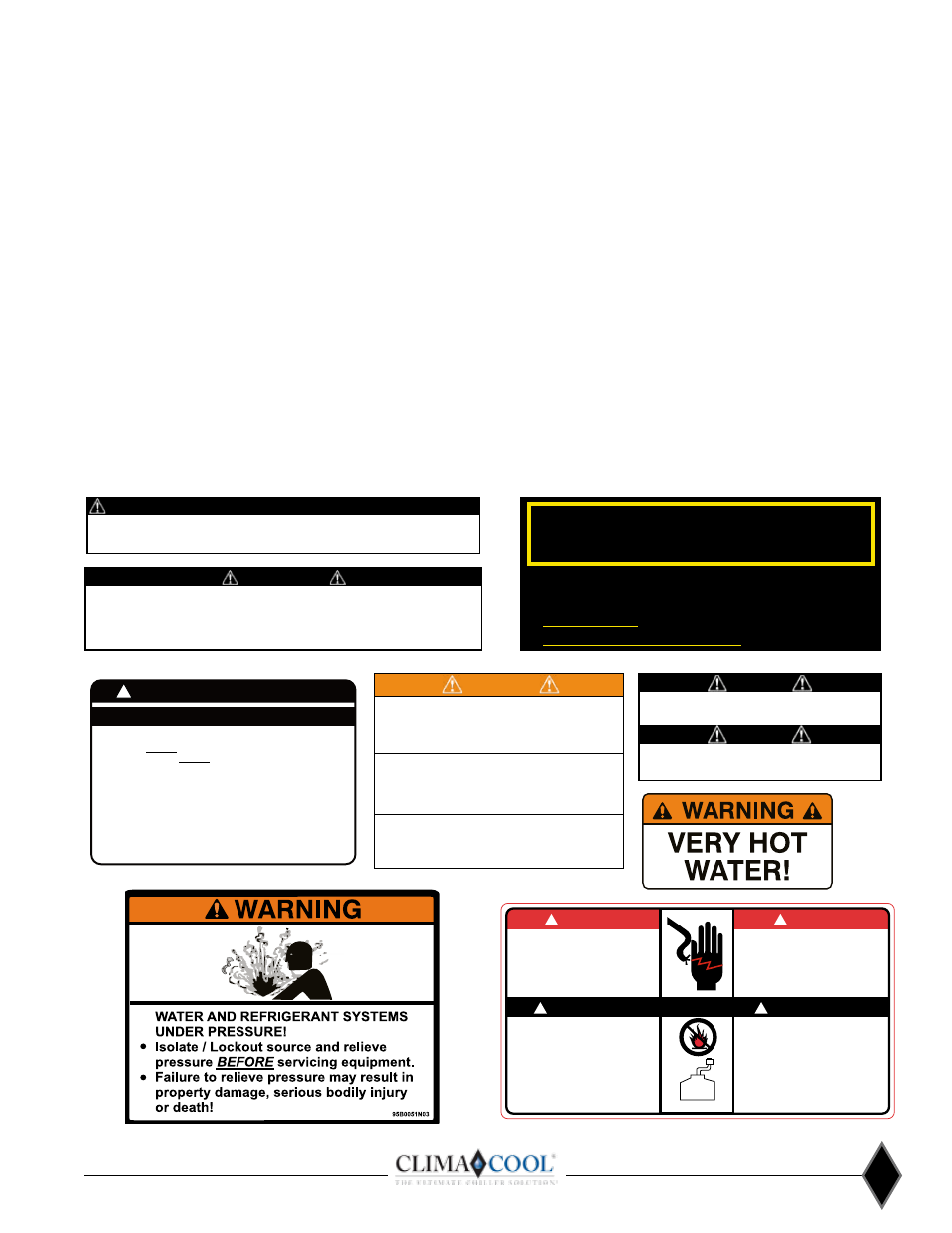

Safety

Throughout this manual warning, danger, caution and

attention notices appear . Read these items carefully before

attempting any installation, service or troubleshooting of

the equipment . All labels on unit access panels must

be observed .

DANGER: Immediate hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING: Potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION: Potentially hazardous situation or an unsafe

practice which, if not avoided, could result in minor or

moderate injury or product or property damage.

ATTENTION: Notification of installed, operation or

maintenance information which is important, but not

hazard related.

CAUTION

• Excessive Chlorine, Undissolved Solids and

other improper water quality conditions

WILL DAMAGE the internal heat exchanger and

WILL VOID YOUR WARRANTY!

• Please refer to the Installation and Operations

Manual for water quality parameters and

maintenance instructions.

For Warranty information, go to www.climacoolcorp.com

95B0051N01

DANGER

!

• Electric shock hazard!

• May result in injury or death!

• Disconnect power supply(ies)

before servicing!

• Refer servicing to qualified

service personnel.

• Risque de choc électrique!

• Résultat de mai dans dommages

ou la mort!

• Debrancher avant d’entreprendre

le dépannage de l’appareil!

• Consulter un réparateur qualifie

pour le dépannage.

DANGER

!

CAUTION

ATTENTION

!

!

• Unit to be serviced by qualified

personnel only.

• Refrigerant system under

pressure.

• Relieve pressure before using

tourch.

• Recover refrigerant and store or

dispose of properly.

• Confier la maintenance á un

technicien qualifie.

• Le systéme frigorifique sous

pression.

• Décomprimer avant d’exposer á

la flamme.

• Récuperér le frigorigene et le

stocker ou le détrire

correctement.

RECOVER

REFRIGERANT

WARNING

To avoid the release of refrigerant into the atmosphere,

the refrigerant circuit of this unit must be serviced only by

technicians who meet local, state and federal proficiency

requirements.

All refrigerant discharged from this unit must be recovered

WITHOUT EXCEPTION. Technicians must follow industry

accepted guidelines and all local, state and federal statutes for

the recovery and disposal of refrigerants.

If a compressor is removed from this unit, system refrigerant

circuit oil will remain in the compressor. To avoid leakage of

compressor oil, the refrigerant lines of the compressor must

be sealed after it is removed.

WARNING

This unit contains HFC-(R410A), an azeotropic mixture of R-32 (Difluoromethane) and R-125 (Pentafluoroethane) .

DO NOT VENT HFC-(R410A) to the atmosphere . The U .S . Clean Air Act requires the recovery of any residual

refrigerant . Do not use R-22 service equipment or components on R410A systems .

WARNING!

WARNING! To avoid possible injury or death due to electrical

shock, open the power supply disconnect switch and secure it

in an open position during installation .

CAUTION!

CAUTION! Use only copper conductors for field installed

electrical wiring . Unit terminals are not designed to accept

other types of conductors .

SAFETY WARNING

High voltage is used to operate this equipment . Failure to observe standard electrical safety procedures may result

in serious injury . Only persons qualified and / or properly trained should attempt to install, operate and maintain this

equipment . These chillers come fully charged with refrigerant . Installation, and start – up should be accomplished by

technicians who are fully certified to handle refrigerants, as required by 40 CRF Part 82, subpart F of the Recycling

and Emissions Reduction Act . Scroll compressors are used in this equipment . Phase verification is required for proper

rotation direction . Incorrect rotation will result in elevated sound and internal overload trip failure .

!

ATTENTION INSTALLER

3 Phase Scroll Compressor Units

• If this unit uses a 3 Phase Scroll Compressor, the following

instructions MUST BE followed:

- Unit power supply MUST BE wired in the proper sequence to avoid

damage to the 3 Phase Scroll Compressor;

- Scroll Compressors with INCORRECT rotation show the following

characteristics:

1.) High sound level;

2.) High suction pressure and low dischage pressure;

3.) Low current draw.

- If any of the three above characteristics exist, swap two of the

three supply wires at the disconnect and recheck compressor for

incorrect rotation.