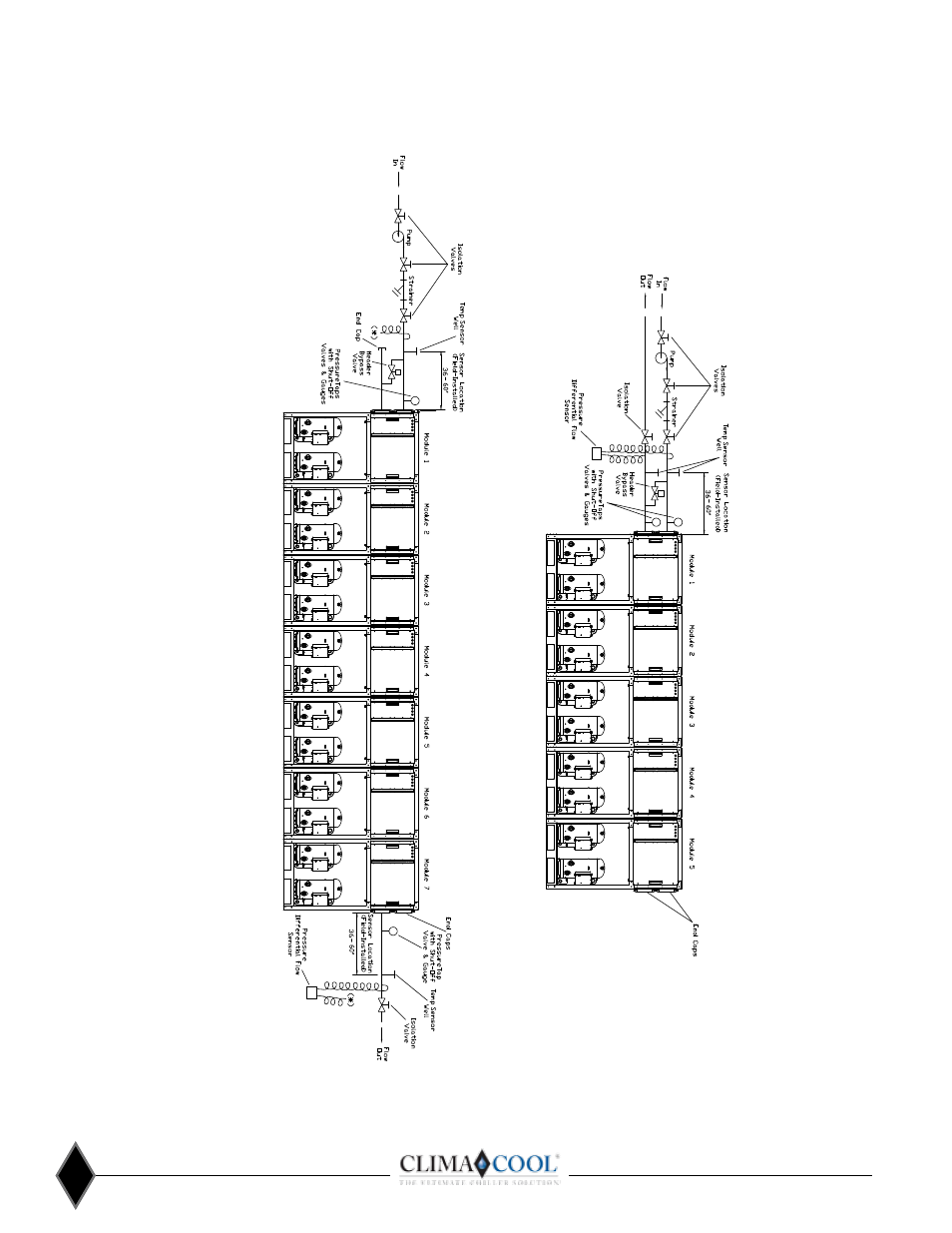

Water piping configurations – ClimaCool UCW_H 30, 50, 70, 85 User Manual

Page 14

www.climacoolcorp.com

12

Water Piping Configurations

N

otes:

1 .

Figures 9 an

d 10 are required pipin

g for proper water regulation

an

d distribution

th

roug

h ClimaCool modular ch

illers

.

2.

M

odule order an

d in

comin

g/outgo

in

g water flo

w as sh

own

in both

Figure 9 an

d 10 can

be set up as eith

er a left-to-rig

ht or rig

ht-to-left con

fig

uration

.

3.

Con

den

ser h

ydron

ic circuit sh

own

. Pipin

g con

fig

uration

s are similar for th

e ch

illed water h

ydron

ic circuit.

4 .

Fo

r con

den

ser/h

eatin

g an

d ch

illed water (evaporator) inlet/outlet location

dimen

sion

s, refer to page 6 - Dimen

sion

Data

.

5.

A pressure differen

tial flow sen

sor is a required safety device for ClimaCool modular ch

illers on

th

e ch

illed an

d con

den

ser/h

eatin

g water circuits.

6 .

A strain

er with

a min

imum of 60 mesh

stain

less steel screen

is a required safety to

protect th

e brazed plate h

eat exch

an

gers on

both

ch

illed an

d con

den

ser/h

eatin

g water sides of th

e system

.

7.

M

aximum water flow rates for both

evaporator an

d con

den

ser/h

eatin

g water h

eader systems fo

r 30, 50 an

d 70 ton

modules in

on

e ban

k is 1,000 g

pm.

8.

M

aximum water flow rates for both

evaporator an

d con

den

ser/h

eatin

g water h

eader systems fo

r 85 ton

modules in

on

e ban

k is 2,400 gpm.

9 . Bypass is

mandatory

fo

r systems utilizin

g motoriz

ed valves

.

10

. Header bypass valve may be in

stalled at eith

er en

d of ban

k .

11

. For over seven

(7) modules, please co

nsult th

e fact

ory

.

Figure 9 - Field Piping Direct Return

Figure 10 - Field Piping Reverse Return