Y” strainer, Basket strainer, Warning – ClimaCool UCW_H 30, 50, 70, 85 User Manual

Page 46: Spare parts, Installation, Maintenance, Installation, operation and maintenance, Y” strainers, Simplex basket strainers

www.climacoolcorp.com

44

“Y” Strainer

Before installing the “Y” strainer, be sure its pressure

rating is correct for the system . If the end connections are

threaded or designed for soldering or brazing, be sure the

piping is straight and not at an angle or offset. If the strainer

has flanged ends, be sure the flanges of the connecting

piping are square with the pipe so that no undue stress is

put on the strainer or piping when tightening the flange

bolts . Tighten in sequence, crossing to opposites .

For maximum efficiency, a differential pressure gauge

installed across the inlet and outlet will indicate pressure

loss due to clogging and may be used as a guide to

determine when cleaning is required . Normally, when

differential pressure reaches 5 - 10 psi, the screen must be

cleaned . If the strainer is equipped with a blow-down valve,

open and flush out until any sediment is removed. If the

strainer is not fitted for blow-down cleaning, (strainer must

be off line), remove the cover or cap and clean the screen.

Reinstall the screen in the strainer in the same position as

before and tighten the cover or cap . Replace the gasket

if necessary .

Keeping a spare, clean screen will minimize shut

down time .

Warning

Individuals performing removal and disassembly should be

provided with suitable protection from possibly hazardous

liquids . Note: Large size “Y” strainers are supplied with

Breech-Lok screens. To remove the screen, rotate the

screen 45

0

and the Breech-Lok will disengage. Minimum

60 mesh screen is required.

Before installing the “Y” strainer, be sure its pressure rating is correct

for the system. If the end connections are threaded or designed for sol-

dering or brazing, be sure the piping is straight and not at an angle or

offset. If the strainer has flanged ends, be sure the flanges of the con-

necting piping are square with the pipe so that no undue stresses are

put on the strainer or piping when tightening flange bolts. Tighten in

sequence, crossing to opposites.

For maximum efficiency, a differential pressure gauge installed across

the inlet and outlet will indicate pressure loss due to clogging and may

be used as a guide to determine when cleaning is required. Normally,

when differential pressure reaches 5–10psi, screen must be cleaned. If

the strainer is equipped with a blow-down valve, open and flush out

until any sediment is removed. If the strainer is not fitted for blow-down

cleaning, (strainer must be off line), remove the cover or cap and clean

the screen. Reinstall the screen in the strainer in the same position as

before and tighten cover or cap. Replace the gasket if necessary.

Keeping a spare, clean screen will minimize shut down time.

Warning

Individuals performing removal and disassembly should be provided

with suitable protection from possibly hazardous liquids.

Note: Large size “Y” strainers are supplied with Breech-Lok screens.

To remove screen, rotate screen 45°, Breech-lok will disengage.

Spare Parts

To order replacement screens or gaskets, which are the only items nor-

mally required, you should specify the following:

A. Size and model number of strainer or casting number as it appears

on the body of the strainer

B. Specify the type of service. For example: water, steam, gas, oil, air.

The working pressure and temperature of the system and the parti-

cle size to be strained out should also be specified.

IOM-MS-YStrainers

“Y” Strainers

Installation, Operation and Maintenance

Limited Warranty: Mueller Steam Specialty warrants each product to be free from defects in material and workmanship under normal usage for a period of one year from the date of original shipment.

In the event of such defects within the warranty period, the Company will, at its option, replace or recondition the product without charge. This shall constitute the sole and exclusive remedy for breach of

warranty, and the Company shall not be responsible for any incidental, special or consequential damages, including without limitation, lost profits or the cost of repairing or replacing other property which is

damaged if this product does not work properly, other costs resulting from labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemi-

cal, or any other circumstances over which the Company has no control. This warranty shall be invalidated by any abuse, misuse, misapplication or improper installation of the product.

THIS WARRANTY IS

IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Any implied warranties that

are imposed by law are limited in duration to one year.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion

or limitation of incidental or consequential damages. Therefore the above limitations may not apply to you. This Limited

Warranty gives you specific legal rights, and you may have other rights that vary from State to State. You should consult

applicable state laws to determine your rights.

USA: 1491 NC Hwy 20 West St.; Pauls, NC 28384; www.muellersteam.com

A Division of Watts Water Technologies, Inc.

Tel: 910-865-8241 Fax: 910-865-6220

Toll Free Phone 1-800-334-6259 Toll Free Fax: 1-800-421-6772

IOM-MS-YStrainers 0641

EDP# 1915978

© Mue

ller Steam Specialty, 2006

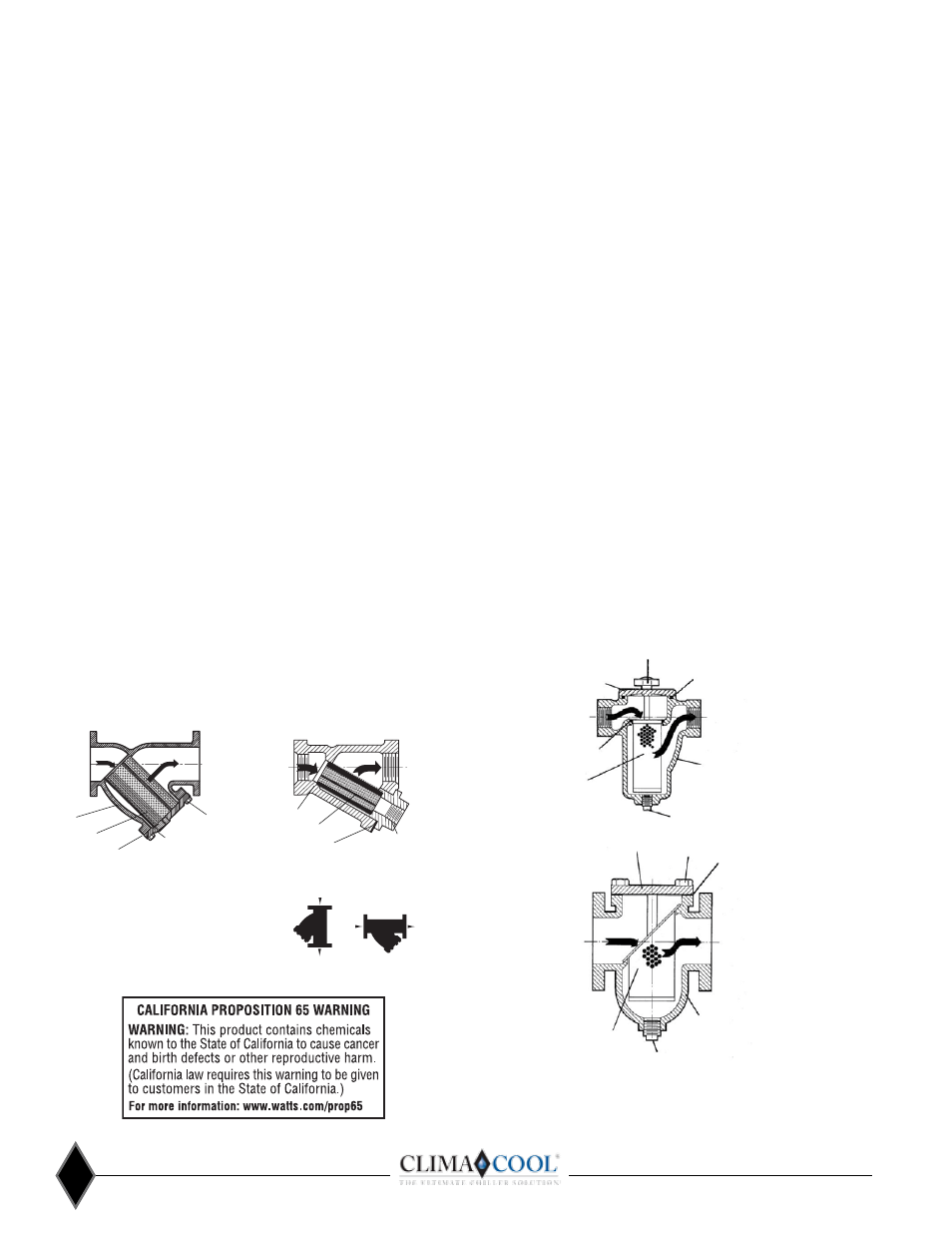

Body

Screen

Gasket

Cover Bolts

Typical flanged end "Y" strainer

Typical threaded "Y" strainer

Mounting Positions

The cover of the "Y" side should face down

Cover

NPT tapping for drain plug

(Optional on some models)

Body

Screen

Gasket

Vertical

Horizontal

Cap

(Tapping for NPT

drain plug optional on

some sizes)

Before installing the “Y” strainer, be sure its pressure rating is correct

for the system. If the end connections are threaded or designed for sol-

dering or brazing, be sure the piping is straight and not at an angle or

offset. If the strainer has flanged ends, be sure the flanges of the con-

necting piping are square with the pipe so that no undue stresses are

put on the strainer or piping when tightening flange bolts. Tighten in

sequence, crossing to opposites.

For maximum efficiency, a differential pressure gauge installed across

the inlet and outlet will indicate pressure loss due to clogging and may

be used as a guide to determine when cleaning is required. Normally,

when differential pressure reaches 5–10psi, screen must be cleaned. If

the strainer is equipped with a blow-down valve, open and flush out

until any sediment is removed. If the strainer is not fitted for blow-down

cleaning, (strainer must be off line), remove the cover or cap and clean

the screen. Reinstall the screen in the strainer in the same position as

before and tighten cover or cap. Replace the gasket if necessary.

Keeping a spare, clean screen will minimize shut down time.

Warning

Individuals performing removal and disassembly should be provided

with suitable protection from possibly hazardous liquids.

Note: Large size “Y” strainers are supplied with Breech-Lok screens.

To remove screen, rotate screen 45°, Breech-lok will disengage.

Spare Parts

To order replacement screens or gaskets, which are the only items nor-

mally required, you should specify the following:

A. Size and model number of strainer or casting number as it appears

on the body of the strainer

B. Specify the type of service. For example: water, steam, gas, oil, air.

The working pressure and temperature of the system and the parti-

cle size to be strained out should also be specified.

IOM-MS-YStrainers

“Y” Strainers

Installation, Operation and Maintenance

Limited Warranty: Mueller Steam Specialty warrants each product to be free from defects in material and workmanship under normal usage for a period of one year from the date of original shipment.

In the event of such defects within the warranty period, the Company will, at its option, replace or recondition the product without charge. This shall constitute the sole and exclusive remedy for breach of

warranty, and the Company shall not be responsible for any incidental, special or consequential damages, including without limitation, lost profits or the cost of repairing or replacing other property which is

damaged if this product does not work properly, other costs resulting from labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemi-

cal, or any other circumstances over which the Company has no control. This warranty shall be invalidated by any abuse, misuse, misapplication or improper installation of the product.

THIS WARRANTY IS

IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Any implied warranties that

are imposed by law are limited in duration to one year.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion

or limitation of incidental or consequential damages. Therefore the above limitations may not apply to you. This Limited

Warranty gives you specific legal rights, and you may have other rights that vary from State to State. You should consult

applicable state laws to determine your rights.

USA: 1491 NC Hwy 20 West St.; Pauls, NC 28384; www.muellersteam.com

A Division of Watts Water Technologies, Inc.

Tel: 910-865-8241 Fax: 910-865-6220

Toll Free Phone 1-800-334-6259 Toll Free Fax: 1-800-421-6772

IOM-MS-YStrainers 0641

EDP# 1915978

© Mue

ller Steam Specialty, 2006

Body

Screen

Gasket

Cover Bolts

Typical flanged end "Y" strainer

Typical threaded "Y" strainer

Mounting Positions

The cover of the "Y" side should face down

Cover

NPT tapping for drain plug

(Optional on some models)

Body

Screen

Gasket

Vertical

Horizontal

Cap

(Tapping for NPT

drain plug optional on

some sizes)

Warning

Individuals performing removal and disassembly should be provided

with suitable protection from possibly hazardous liquids.

Knob and clamp type quick opening covers should not be used for high

temperature service. Consult factory for recommendations.

Installation

Before installing the simplex basket strainer, be sure its pressure rating

is correct for the system. If the end connections are threaded, be sure

the piping is straight and not at an angle or offset. If the strainer has

flanged ends, be sure the flanges of the connecting piping are square

with the pipe so that no undue stresses are put on the strainer or pip-

ing when tightening flange bolts. Tighten bolts in sequence crossing to

opposites.

Maintenance

For maximum efficiency, a differential pressure gauge installed across

the inlet and outlet will indicate pressure loss due to clogging and may

be used, as a guide to determine when cleaning is required. If the

strainer is not set up for backwash cleaning, remove the cover access

to the basket. After cleaning, replace the basket in the same position

as before and tighten cover. Replace the gasket or O-ring if necessary.

Keeping a spare, clean basket will minimize shut down time.

Spare Parts

To order replacement baskets or gaskets and O-rings, which are the

only items normally required, specify the following.

A. Size and model number of strainer or casting number as it appears

on the body of the strainer.

B. Specify service. For example: water, steam, gas, air, oil. The work-

ing pressure and temperature of the system and particle size to be

strained out should also be specified.

IOM-MS-Simplex

Simplex Basket Strainers

Installation, Operation and Maintenance

Limited Warranty: Mueller Steam Specialty warrants each product to be free from defects in material and workmanship under normal usage for a period of one year from the date of original shipment.

In the event of such defects within the warranty period, the Company will, at its option, replace or recondition the product without charge. This shall constitute the sole and exclusive remedy for breach of

warranty, and the Company shall not be responsible for any incidental, special or consequential damages, including without limitation, lost profits or the cost of repairing or replacing other property which is

damaged if this product does not work properly, other costs resulting from labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemi-

cal, or any other circumstances over which the Company has no control. This warranty shall be invalidated by any abuse, misuse, misapplication or improper installation of the product.

THIS WARRANTY IS

IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Any implied warranties that

are imposed by law are limited in duration to one year.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion

or limitation of incidental or consequential damages. Therefore the above limitations may not apply to you. This Limited

Warranty gives you specific legal rights, and you may have other rights that vary from State to State. You should consult

applicable state laws to determine your rights.

USA: 1491 NC Hwy 20 West St.; Pauls, NC 28384; www.muellersteam.com

A Division of Watts Water Technologies, Inc.

Tel: 910-865-8241 Fax: 910-865-6220

Toll Free Phone 1-800-334-6259 Toll Free Fax: 1-800-421-6772

IOM-MS-Simplex 0641

EDP#1915979

© Mue

ller Steam Specialty, 2006

SIMPLEX BASKET STRAINERS SHOULD BE INSTALLED IN

THE POSITION SHOWN IN THE ILLUSTRATIONS ABOVE

Cover Knobs

O-Ring

O-Ring

Body

Gasket

Body

NPT Plug

NPT Plug

Basket

Basket

Cover

Cover

Cover Bolts

Basket Strainer

Installation

Before installing the simplex basket strainer, be sure

its pressure rating is correct for the system . If the end

connections are threaded, be sure the piping is straight and

not at an angle or offset. If the strainer has flanged ends, be

sure the flanges of the connecting piping are square with

the pipe so that no undue stresses are put on the strainer

or piping when tightening flange bolts. Tighten bolts in

sequence crossing to opposites .

Maintenance

For maximum efficiency, a differential pressure gauge

installed across the inlet and outlet will indicate pressure

loss due to clogging and may be used, as a guide, to

determine when cleaning is required . If the strainer is not

set up for backwash cleaning, remove the cover access to

the basket . After cleaning, replace the basket in the same

position as before and tighten the cover . Replace the gasket

or O-ring if necessary . Keeping a spare, clean basket will

minimize shut down time .

Warning

Individuals performing removal and disassembly should be

provided with suitable protection from possibly hazardous

liquids . Knob and clamp type quick opening covers should

not be used for high temperature service . Consult factory

for recommendations . Note: Minimum 60 mesh screen

is required.

Basket Strainers should be installed in the position shown in the

illustrations above .

Before installing the “Y” strainer, be sure its pressure rating is correct

for the system. If the end connections are threaded or designed for sol-

dering or brazing, be sure the piping is straight and not at an angle or

offset. If the strainer has flanged ends, be sure the flanges of the con-

necting piping are square with the pipe so that no undue stresses are

put on the strainer or piping when tightening flange bolts. Tighten in

sequence, crossing to opposites.

For maximum efficiency, a differential pressure gauge installed across

the inlet and outlet will indicate pressure loss due to clogging and may

be used as a guide to determine when cleaning is required. Normally,

when differential pressure reaches 5–10psi, screen must be cleaned. If

the strainer is equipped with a blow-down valve, open and flush out

until any sediment is removed. If the strainer is not fitted for blow-down

cleaning, (strainer must be off line), remove the cover or cap and clean

the screen. Reinstall the screen in the strainer in the same position as

before and tighten cover or cap. Replace the gasket if necessary.

Keeping a spare, clean screen will minimize shut down time.

Warning

Individuals performing removal and disassembly should be provided

with suitable protection from possibly hazardous liquids.

Note: Large size “Y” strainers are supplied with Breech-Lok screens.

To remove screen, rotate screen 45°, Breech-lok will disengage.

Spare Parts

To order replacement screens or gaskets, which are the only items nor-

mally required, you should specify the following:

A. Size and model number of strainer or casting number as it appears

on the body of the strainer

B. Specify the type of service. For example: water, steam, gas, oil, air.

The working pressure and temperature of the system and the parti-

cle size to be strained out should also be specified.

IOM-MS-YStrainers

“Y” Strainers

Installation, Operation and Maintenance

Limited Warranty: Mueller Steam Specialty warrants each product to be free from defects in material and workmanship under normal usage for a period of one year from the date of original shipment.

In the event of such defects within the warranty period, the Company will, at its option, replace or recondition the product without charge. This shall constitute the sole and exclusive remedy for breach of

warranty, and the Company shall not be responsible for any incidental, special or consequential damages, including without limitation, lost profits or the cost of repairing or replacing other property which is

damaged if this product does not work properly, other costs resulting from labor charges, delays, vandalism, negligence, fouling caused by foreign material, damage from adverse water conditions, chemi-

cal, or any other circumstances over which the Company has no control. This warranty shall be invalidated by any abuse, misuse, misapplication or improper installation of the product.

THIS WARRANTY IS

IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Any implied warranties that

are imposed by law are limited in duration to one year.

Some States do not allow limitations on how long an implied warranty lasts, and some States do not allow the exclusion

or limitation of incidental or consequential damages. Therefore the above limitations may not apply to you. This Limited

Warranty gives you specific legal rights, and you may have other rights that vary from State to State. You should consult

applicable state laws to determine your rights.

USA: 1491 NC Hwy 20 West St.; Pauls, NC 28384; www.muellersteam.com

A Division of Watts Water Technologies, Inc.

Tel: 910-865-8241 Fax: 910-865-6220

Toll Free Phone 1-800-334-6259 Toll Free Fax: 1-800-421-6772

IOM-MS-YStrainers 0641

EDP# 1915978

© Mue

ller Steam Specialty, 2006

Body

Screen

Gasket

Cover Bolts

Typical flanged end "Y" strainer

Typical threaded "Y" strainer

Mounting Positions

The cover of the "Y" side should face down

Cover

NPT tapping for drain plug

(Optional on some models)

Body

Screen

Gasket

Vertical

Horizontal

Cap

(Tapping for NPT

drain plug optional on

some sizes)