Compressor information, Attention installer, Compressor rotation – ClimaCool UCW_H 30, 50, 70, 85 User Manual

Page 36: Compressor anti-short cycle timer, Compressor lubrication, Oil type, Oil levels, Adding oil

www.climacoolcorp.com

34

Compressor Information

Model UCW/H uses scroll compressors which are highly

efficient and extremely reliable. The information contained

in this manual will be useful for their care .

Compressor Rotation

All scroll-type machines are unidirectional and will only

compress in one direction . Operating in the reverse rotation

can be destructive and will be indicated by a loud operating

noise together with a lack of compression .

Compressor Anti-Short Cycle Timer

Built into the logic of the CoolLogic Control System is an anti-

short cycle timer which will prevent the compressors from

restarting immediately following a compressor shutdown .

Minimum on 75 seconds and minimum off 200 seconds.

Compressor Lubrication

The compressor operates on a sealed system and oil can

only be lost if a leak occurs . There are few cases when oil

will need to be added to a machine in normal operation .

Oil Type

The oil in scroll compressors will be either Polyolester type

oil (POE) or polyvinyl-ether type oil (PVE) . Both refrigerant

oils require special handling and should be protected

from contamination . They are extremely hygroscopic and

will absorb moisture rapidly from the air . It is strongly

recommended to store and dispense both oils from sealed

metal cans . Note: Refer to compressor name plate for

proper oil type. Different oils cannot be mixed.

Oil Levels

The oil level in the compressor should be checked with the

compressor running . The compressor oil level may vary

during operation and particularly on the startup . The normal

operating compressor oil level should be between

1/3 and 1/2

of the sight glass . During operation, a certain amount of oil

is carried out into the refrigerant system . The system has

been designed to bring the oil back to the compressor . If the

level in the sight glass falls, it may be due to the operating

conditions and enough time should be given to allow the oil

to return before more oil is added . This could take up to six

hours of operation . The compressor should not be allowed

to operate with less than

1/8 of the sight glass for longer

than four to six hours .

Adding Oil

The compressor must never be ran in a vacuum . A suitable

hydraulic pump should be used to add oil and reserved for

this process . It is imperative that oil type be verified prior

to adding to a compressor. Oil should only be added to a

compressor while it is operating to observe valid oil sight

glass levels . Oil is pressure-injected either into a gauge

connection on the suction line or injected into the oil

process port at the bottom of the compressor housing . Only

enough oil should be added to raise the level above the

⅓

sight glass point .

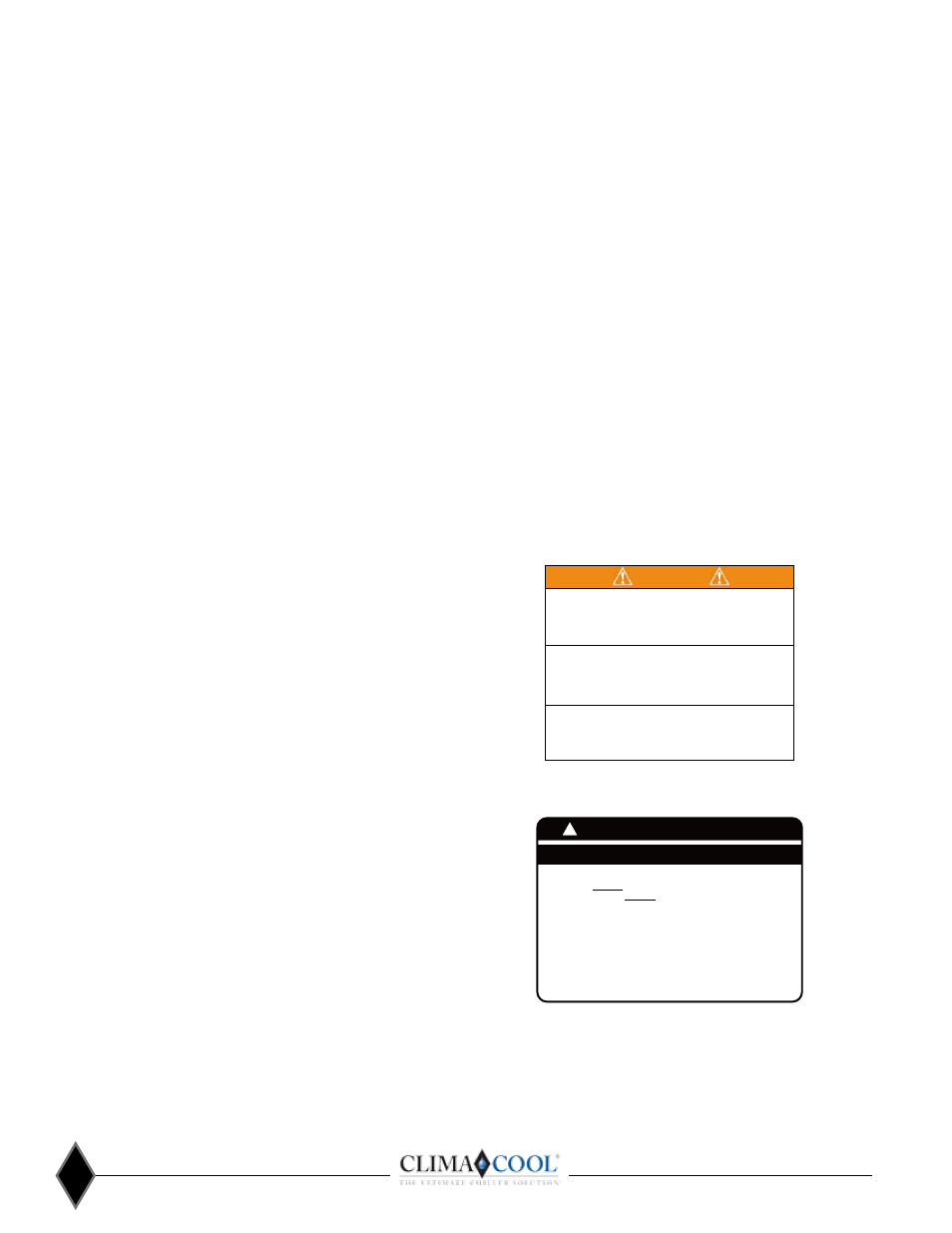

WARNING

To avoid the release of refrigerant into the atmosphere,

the refrigerant circuit of this unit must be serviced only by

technicians who meet local, state and federal proficiency

requirements.

All refrigerant discharged from this unit must be recovered

WITHOUT EXCEPTION. Technicians must follow industry

accepted guidelines and all local, state and federal statutes for

the recovery and disposal of refrigerants.

If a compressor is removed from this unit, system refrigerant

circuit oil will remain in the compressor. To avoid leakage of

compressor oil, the refrigerant lines of the compressor must

be sealed after it is removed.

!

ATTENTION INSTALLER

3 Phase Scroll Compressor Units

• If this unit uses a 3 Phase Scroll Compressor, the following

instructions MUST BE followed:

- Unit power supply MUST BE wired in the proper sequence to avoid

damage to the 3 Phase Scroll Compressor;

- Scroll Compressors with INCORRECT rotation show the following

characteristics:

1.) High sound level;

2.) High suction pressure and low dischage pressure;

3.) Low current draw.

- If any of the three above characteristics exist, swap two of the

three supply wires at the disconnect and recheck compressor for

incorrect rotation.