3 - commissioning – CEMB USA C65 (E) User Manual

Page 5

I 0206 - 5

A

B

Spring

DC

WD

Cone

GB

3 - COMMISSIONING

3.1 - ANCHORING

The machine can be operated on any flat non-resilient floor.

Make sure that the machine rests solely on the three support points provided (fig. 2a).

It is advisable to secure the system to the ground using the specific feet (see Figure 2a) in the event of

continual use with wheels weighing over 35 Kg.

3.2 - ELECTRICAL CONNECTION

The machine is supplied with a single phase mains cable plus earth (ground).

The supply voltage (and mains frequency) is given on the machine nameplate. It may NOT be changed.

Connection to the mains should always be made by expert personnel.

The machine should not be started up without proper earth (ground) connection.

Connection to the mains should be through a slow acting safety switch rated at 4A (230V) or 10A (115V) .

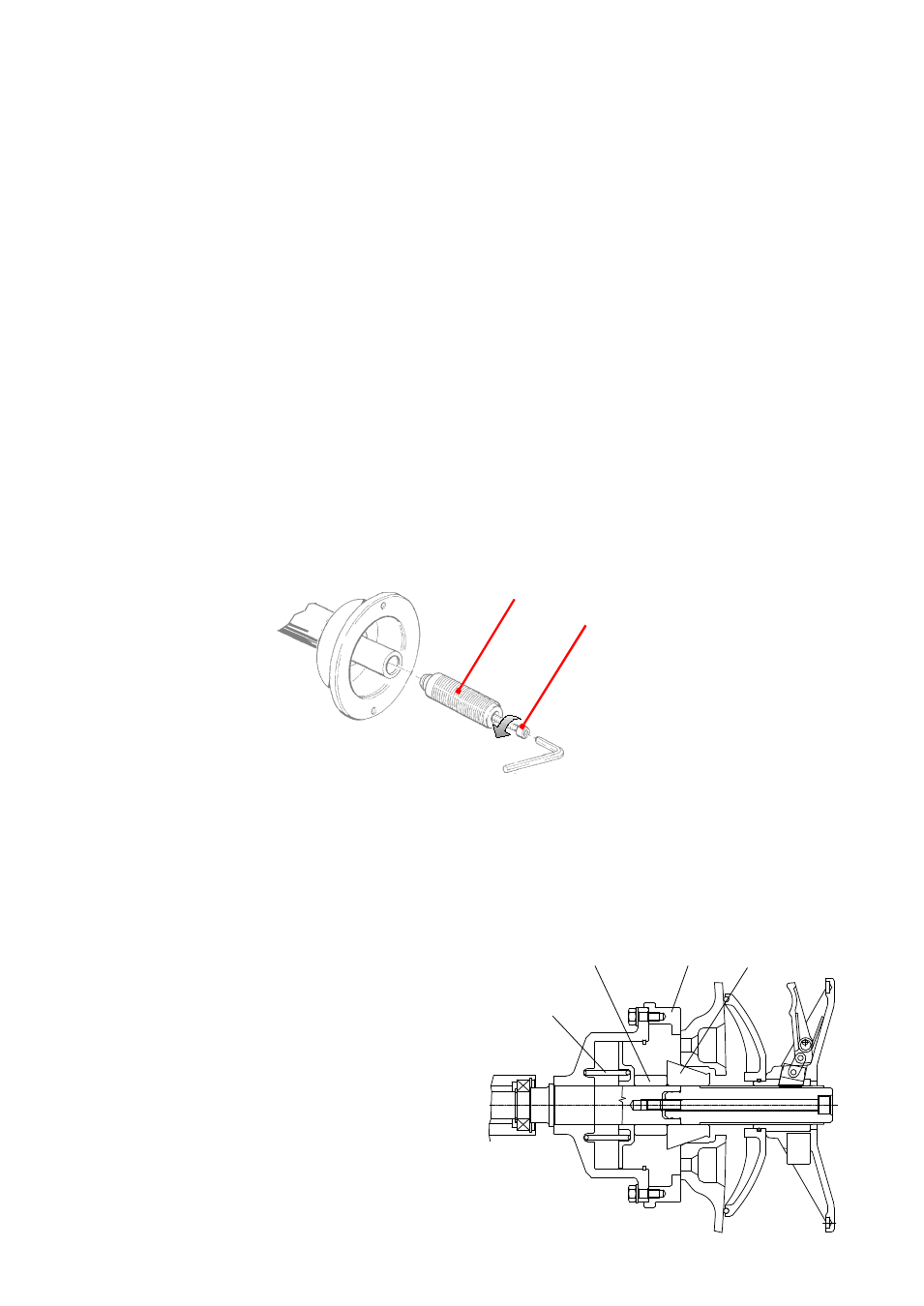

3.3 - ADAPTER MOUNTING

The balancing machine is supplied complete with cone adapter for fastening wheels with central bore.

Other optional adapters can be mounted:

a) Back-off screw B and remove threaded end-piece A.

b) Fit the new adapter.

Fig. 4

3.5 - SPACER WD

When balancing very wide wheels (9”), there is

not enough space to turn the distance gauge.

To withdraw the wheel from the machine side,

fit spacer WD on the adapter body and secure

it with the standard issue nuts. When centring

the wheel with the cone on the inside, fit the DC

spacer to obtain spring thrust.

3.4 - GUARD MOUNTING AND ADJUSTMENT

a) Fasten the components to the base as illustrated in specific exploded view.

b) The position of the wheel guard when closed can be adjusted with relative screw accessible at the back.

Correct position is the one which keeps the tube exactly horizontal with wheel guard closed.

c) Check that the microswitch is held down when the guard is closed.

d) Adjust the angular position of microswitch control.