1 presetting of tolerance on the machine, 3 value of unbalance corresponding to eccentricity, 6 eccentricity measurement (optional) – CEMB USA C73-L SE (B) User Manual

Page 17

17

A

B

Use and maintenance manual Rev. 10-2009

ENGLISH

SOLUTION: Rotate the tyre on the rim by 180°

RESULT: no improvement is obtained.

5.5.1 Presetting of tolerance on the

machine

There is no general rule concerning acceptability of an eccen-

tricity value . As a fi rst approximation we consider it correct

to use a threshold of 1 to 1.5 mm. The E/ECE/324 standard

prescribes 1.5 mm as max. eccentricity of a rebuilt tyre.

5.5.2 Value of static unbalance, correlated

with eccentricity

Clear indication is given in the Measurement screen of both

the value and position of the static unbalance as well as the

eccentricity. In fact, it is interesting to check the correlations

of the two values, above all of the two positions. When the

two positions have a similar angle (± 30° one from the other),

there is a clear sign that an eccentricity is present which

can be compensated by matching.

5.5.3 Value of unbalance corresponding to

eccentricity

For user’s reference, the centrifugal force is calculated corre-

sponding to a certain speed, compared to the force generated

by the eccentricity present on the tyre (calculated with an

approximate average elastic constant).

5.6 ECCENTRICITY MEASUREMENT

(OPTIONAL)

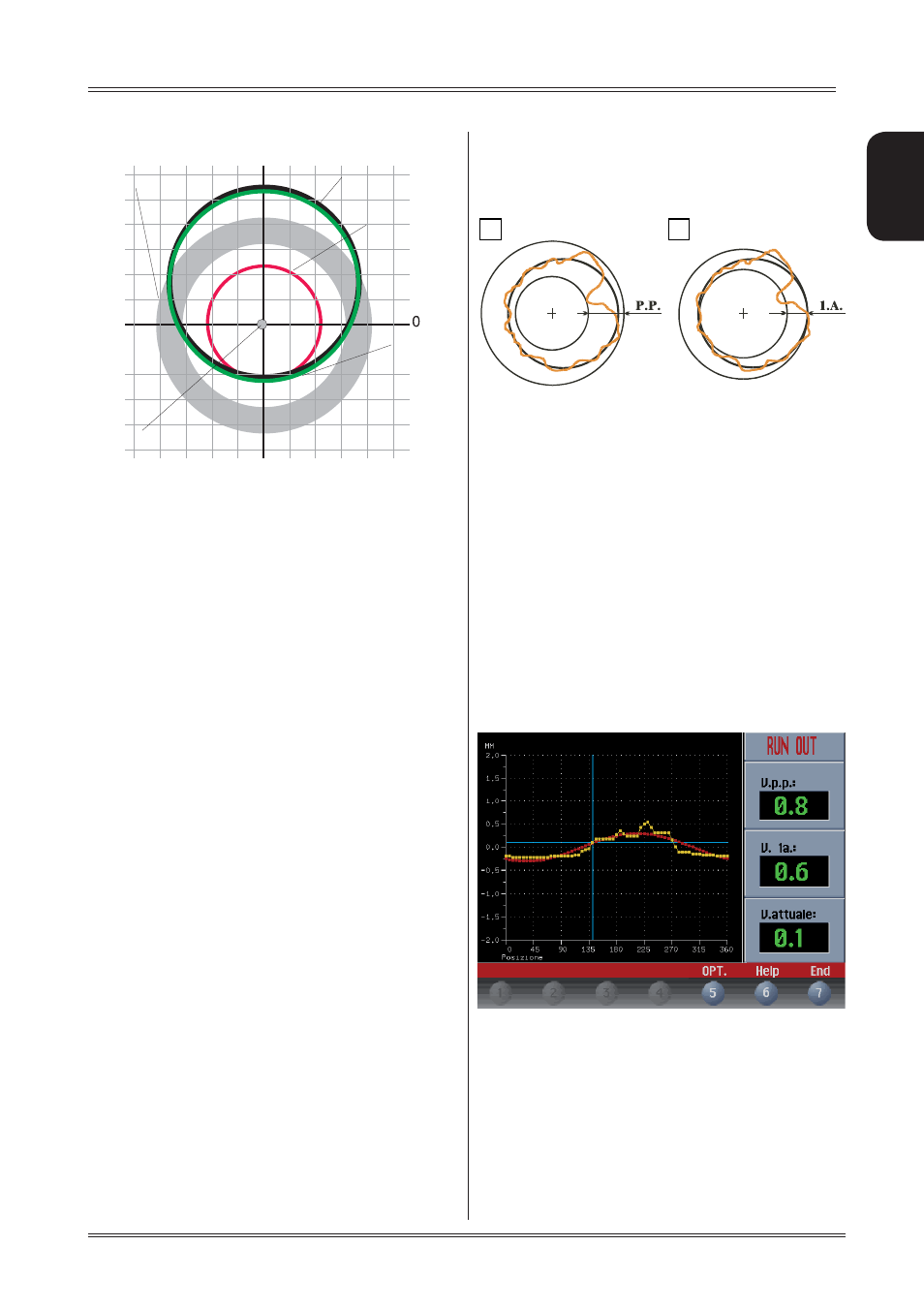

The much enlarged fi gures show the outer tyre surface

and axis of wheel rotation.

Fig. A - shows measurement of the total Peak-to-Peak

eccentricity defi ned as maximum radial deviation of the tyre

surface.

Fig. B - shows measurement of the eccentricity of the 1st

harmonic, i.e. the eccentricity of that circle which “recopies”

the tyre shape, by averaging the local deviations of the tyre

from the round shape.

Obviously the P.P. measurement is normally greater than that

of the 1st harmonic. Tyre manufacturers normally supply two

different tolerances for the two eccentricities.

At the end of the balancing spin it is possible to automatically

measure the eccentricity of the tyre through the SONAR sensor

installed on the guard. The sensor should be positioned by

hand in front of the tyre tread.

GRAPH 1 (yellow) : represents the actual Peak-to-Peak

eccentri-city.

GRAPH 2 (red) : represents the eccentricity of the 1st harmo-

nic. For a wheel in optimum conditions, such graph should

approach a straight line.

While rotating the wheel, the screen cursor indicates the

current value, with the stage referred to the eccentricity me-

asurement sensor.

Example 3

Rim 0 mm

Tyre + 1.2 mm

Wheel + 1,2 mm

Eccentricity of the wheel cannot be compensated by the

rotation because the rim is perfect!

wheel

rim

tyre

rotation axle

Ideal wheel

Use of the wheel balancer