3 automatic minimization of static unba- lance, 5 when and why matching, English – CEMB USA C73-L SE (B) User Manual

Page 16

16

s

sx

x

g

g

g

g

d

dx

x

5

50

0°°

s

sx

x

g

g

g

g

d

dx

x

4

4 g

g

3

3 g

g

1

1 g

g

6

6 g

g

s

sx

x

g

g

g

g

d

dx

x

s

sx

x

g

g

g

g

d

dx

x

s

sx

x

g

g

g

g

d

dx

x

Use and maintenance manual Rev. 10-2009

ENGLISH

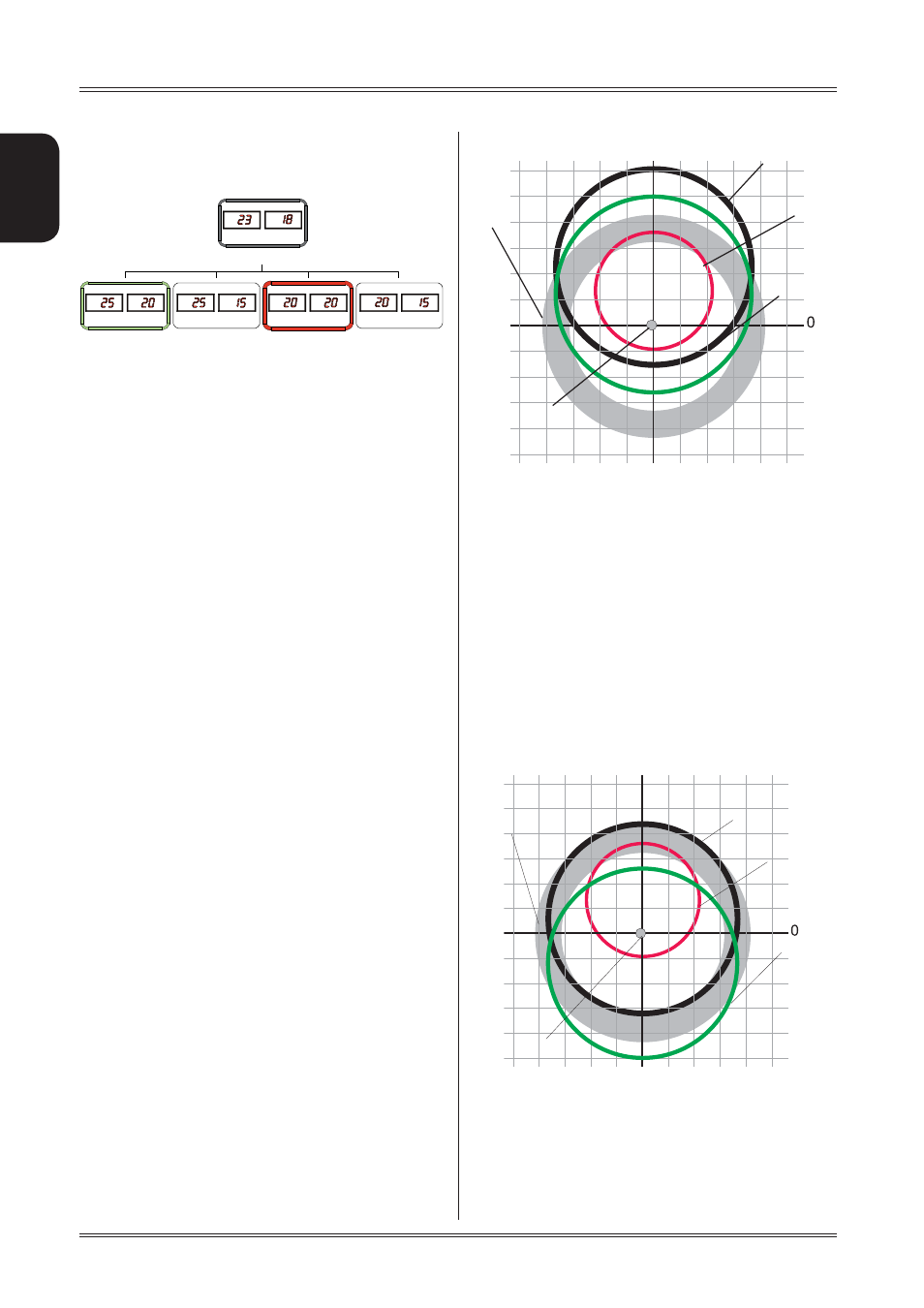

5.4.3 Automatic minimization of static unba-

lance

This program is designed to improve the quality of balancing

without any mental effort or loss of time by the operator. In

fact by using the normal commercially available weights, with

pitch of 5 in every 5 g, and by applying the two counterweights

which a conventional wheel balancer rounds to the nearest

value, there could be a residual static unbalance of up to 4

g. The damage of such approximation is emphasized by the

fact that static unbalance is cause of most of disturbances

on the vehicle. This new function, resident in the machine,

automatically indicates the optimum entity of the weights

to be applied by approximating them in an “intelligent” way

according to their position in order to minimize residual static

unbalance.

5.5

WHEN AND WHY MATCHING

The software associated with eccentricity measurement is

a powerful tool for determining the need to perform relative

rotation between the rim and tyre in order to reduce the eccen-

tricity of the wheel down to acceptable limits. The principle

adopted is based on the consideration that a rim with acceptable

tolerance, mounted with an acceptable tyre, can statistically

generate a total eccentricity which is not acceptable but can

be improved by matching.

Generally speaking, rim measurement is not necessary,

accurate or useful because:

To measure the rim it is necessary to remove the tyre.

▪

There can by coarse errors on the outside (e.g. alumi-

nium wheels!)

The two rim sides can be eccentric in a very different

▪

way. Therefore to which one to make reference? What

is the effect on the tyre mounted?

To improve the eccentricity of a wheel,

▪

the rim should be

eccentric, to compensate the tyre. And viceversa.

If after a rotation by 180° of a wheel, the value is still

▪

out-of-tolerance, either the tyre or rim are too eccentric:

One of the two must be replaced!

SOLUTION: Rotate the tyre on the rim by 180°

RESULT: wheel eccentricity 0.3 - 0.4 mm (in tolerance)

wheel

rim

tyre

rotation axle

Ideal wheel

Example 1

Rim + 0.8 mm

Tyre + 0.6 mm

Wheel + 1.3 mm

Eccentricity of the wheel is excessive, due to an acceptable

rim or tyre but randomly placed in an “unfortunate” relative

position.

Example 2

Rim + 0.8 mm

Tyre - 0.6 mm

Wheel + 0.3 mm

Eccentricity of the single items has been compensated.

The wheel is acceptable.

Initial unbalance

phase shift

Possible approximations

residual static

residual static

residual static

Choice with minimum

static residual

With conventional

wheel balancer

residual static

Use of the wheel balancer