C.E. Niehoff & Co. N1509/N1511/N2003 Troubleshooting Guides User Manual

Page 5

Page 5

TG0014D

Section 3: Advanced Troubleshooting

(CONT’D)

Test for battery voltage at alternator 28 V B+ terminal. Does battery voltage exist?

Yes

No

Repair vehicle wiring as necessary. Continue test.

Run engine and re-test charging circuit for operation.

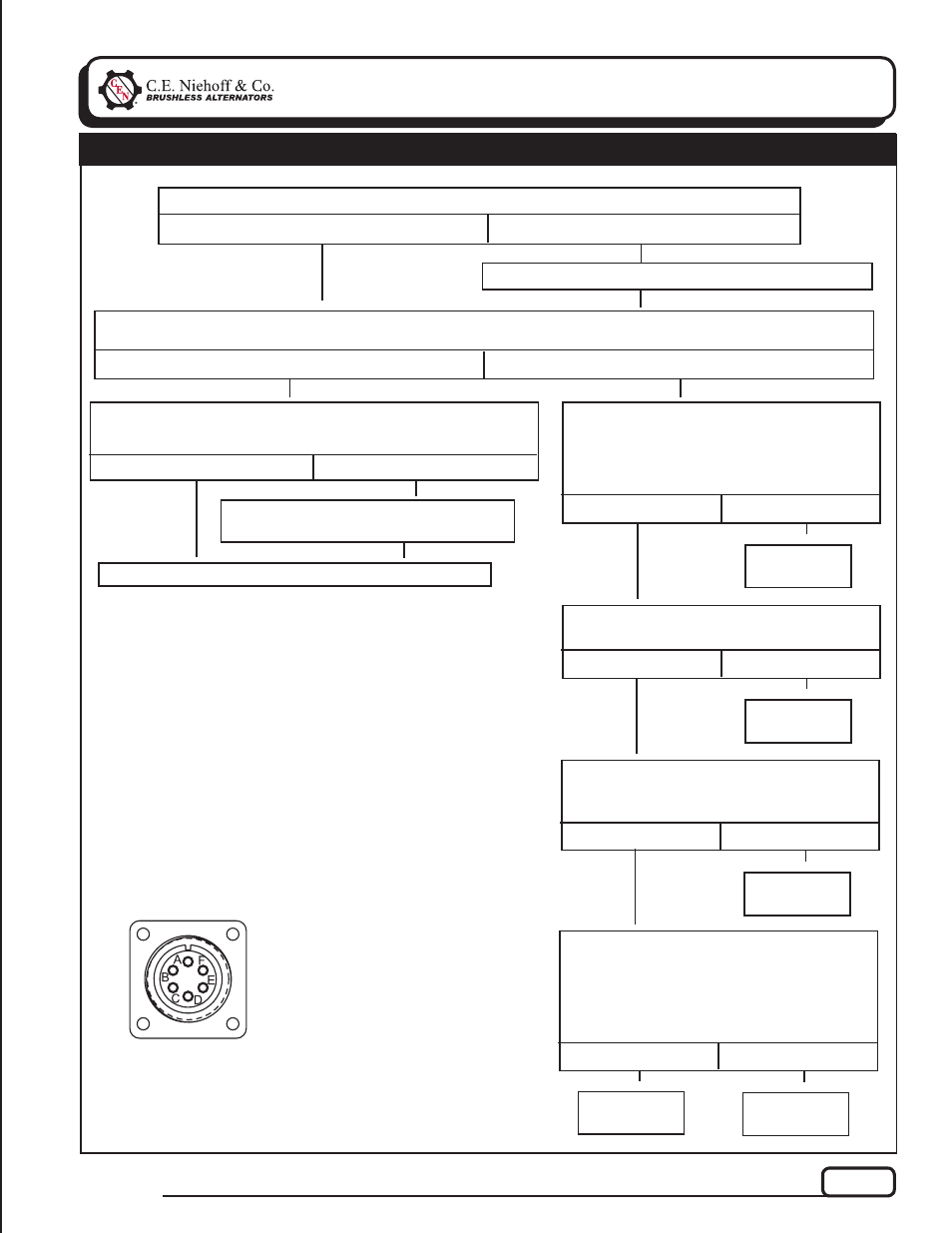

Chart 1 – 28 V LED Flashing AMBER – No 28V Alternator Output – Test Charging Circuit

Jumper 28 V B+ terminal on alternator to E terminal on regulator. Wait 10 seconds. Run engine. Does

alternator charge and is 28 V LED flashing GREEN?

Yes

No

Turn off engine, leave key on. Remove jumper wire. Go to E

terminal on regulator. Test for battery voltage going into E

terminal from battery. Does battery voltage exist?

Yes

No

STATIC TEST – MASTER SWITCH ON, KEY ON, ENGINE OFF

Repair vehicle circuit to E terminal. Ve-

hicle charging circuit test is complete.

T

T

T

T

T

T

Yes

Turn off engine, leave key on. Connect

jumper wire from pin A in harness plug to

B– terminal on alternator. Spark will occur.

Touch steel tool to shaft to detect significant

magnetism. is shaft magnetized?

No

T

T

T

Alternator is

defective.

T

Figure 3 – Alternator-to-Regulator Harness Plug

PIN CONNECTIONS

Pin A

F–

Pin B

SCR Gate

Pin C

B–

Pin D

28 V B+

Pin E

14V B+

Pin

F

AC

Yes

Test for battery voltage at pin D in harness

plug. Does battery voltage exist?

No

Alternator is

defective.

T

T

Yes

Connect DMM red lead to pin C on

harness plug. Connect black leak to alter-

nator B– terminal. Does continuity exist?

No

Alternator is

defective.

T

T

Yes

Set DMM to diode test. Connect DMM red

lead to pin F on harness plug. Connect

black leak to alternator B+ terminal.

Reverse leads. Meter should read OL in

one direction, and voltage drop in the other

direction. Do tests prove out?

No

Alternator is

defective.

T

Regulator is

defective.

T