Page 5 tg32d – C.E. Niehoff & Co. C803D Troubleshooting Guides User Manual

Page 5

Page 5

TG32D

Section C: On-Vehicle Troubleshooting

(CONT’D)

No Alternator Output – Test Charging Circuit

• TEST MEASUREMENTS ARE TAKEN ON HARNESS PLUG AT ALTERNATOR. TEST MEASUREMENT AT AN

EXTENDED HARNESS PLUG MAY AFFECT RESULTS.

• REMOTE-MOUNTED REGULATORS: CHECK CONDITION OF FUSES IN WIRING HARNESS BEFORE TROUBLE-

SHOOTING.

• BEFORE STARTING DIAGNOSTIC SEQUENCE, VERIFY THE FOLLOWING AND REPAIR/REPLACE IF NOT

TO SPEC:

—BATTERIES FOR STATE-OF-CHARGE (24.5-25.5 V), CONDITION, AND SECURE CONNECTIONS

—MASTER BATTERY SWITCH FOR FUNCTION

If you have questions about your alternator or any of these instructions, or if you need to locate a Factory Authorized Service Dealer, please contact us at:

C. E. Niehoff & Co.• 2021 Lee Street • Evanston, IL 60202 USA

TEL: 800.643.4633 USA and Canada • TEL: 847.866.6030 outside USA and Canada • FAX: 847.492.1242

E-mail us at [email protected]

MASTER BATTERY SWITCH ON, KEY ON, ENGINE ON: Test for battery voltage at B+ terminal on alternator to

ground, then at IGN terminal on regulator to ground (A2-363: unplug 3-pin harness plug and test pin C [Eng] at

plug to ground; A2-341 regulator: See page 2 for more information). Does battery voltage exist at both locations?

Yes

No

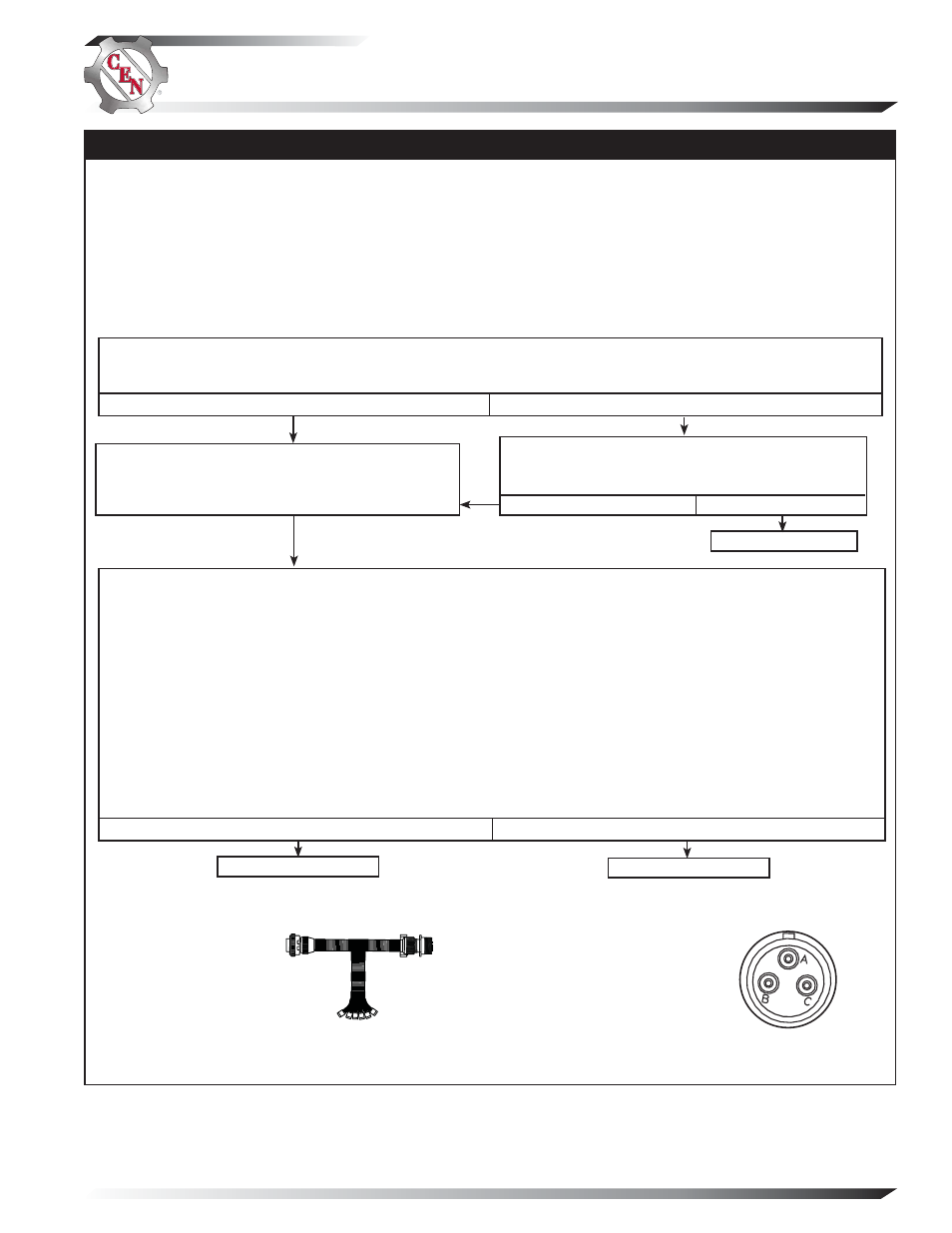

Figure 8 – CEN 6-pin A10-114 Inline Harness Tool

Socket Connections

SOCKET CONNECTIONS

Socket A Not used

Socket B Not used

Socket C B –

Socket D B+

Socket E Phase

Socket F F+

MASTER BATTERY SWITCH ON, KEY ON, ENGINE OFF: Readings of all four tests must pass.

1. Battery voltage test: Connect DMM red lead to socket D in test tool. Connect DMM black lead to socket C in test

tool. Battery voltage should exist.

2. Field coil resistance test: Set DMM on Ohms test. Field resistance between sockets F and C in test tool should

measure nominal 1.0-1.5 ± 0.2 ohms. Field coil is defective if reading is less than 0.5 ohms or greater than 3 ohms.

3. Significant magnetism test:

a. Securely connect one end of a jumper wire to socket F in test tool.

b. Momentarily (1 sec.) touch other end of jumper wire to alternator B+ terminal. Spark will occur at B+ terminal.

Touch steel tool to shaft to detect significant magnetism.

4. Phase supply test: Set DMM to diode test. Connect DMM black lead to socket E in test tool. Connect red lead to

alternator B+ terminal. DMM should read blocking in this direction. Then reverse leads. DMM should read flow

in this direction. Repeat for socket E and B– terminal. Tests should read flow in one direction and blocking in

the other direction.

Yes

No

Alternator is defective.

Disconnect 6-pin alternator-to-regulator harness

plug at regulator and connect CEN A10-114 inline

test tool to harness plug end only. Make sure

connections are secure.

Regulator is defective.

Repair vehicle wiring as necessary. Run engine and

re-test charging circuit. Is charging system perform-

ing properly?

System is operative.

No

Yes

A B C D E F

Figure 9 – A2-363 3-pin Harness

Pin Connections

PIN CONNECTIONS

Pin A D+

Pin B Phase out

Pin C Eng