C.E. Niehoff & Co. C633 Troubleshooting Guides User Manual

Page 5

Page 5

TG80A

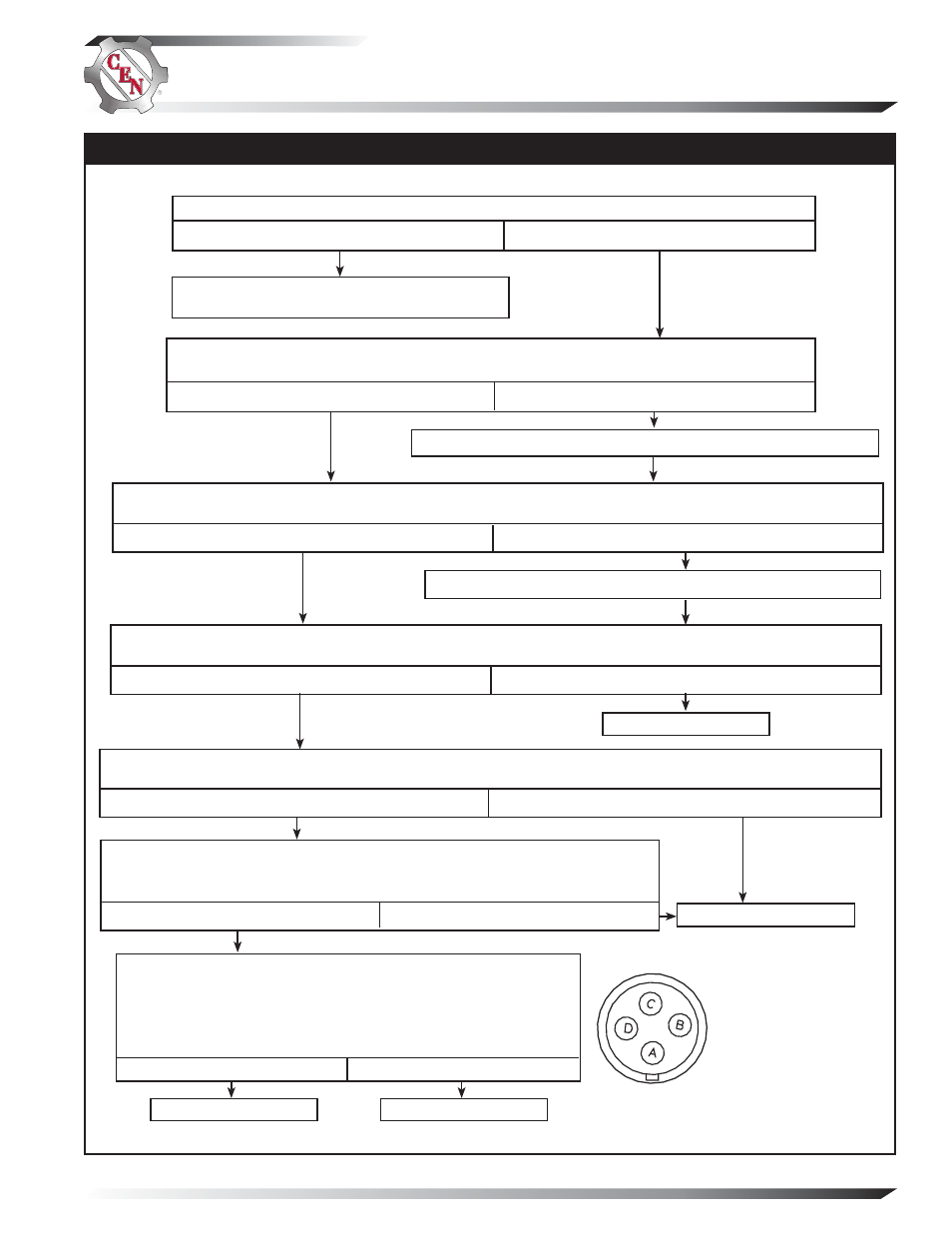

Shut off engine. With key off, engine off: Test for battery voltage at alternator 28 V B+ terminal.

Does battery voltage exist?

Yes

No

Repair vehicle ignition circuit wiring as necessary. Continue test.

Chart 2 – No 28V Alternator Output – Test Charging Circuit

With DMM, check resistance across field coil. Connect red lead of DMM to socket A in alternator-to-regulator

harness plug. Connect black lead to B+ terminal on alternator. Does meter show 1.8 to 2.2 ohms?

Yes

No

STATIC TEST – KEY ON, ENGINE OFF

Yes

Test phase signal into regulator (AC). Set meter to diode tester:

Connect red lead of DMM to socket C of regulator harness and

black lead to socket B. Meter should show voltage drop value.

Then reverse meter lead connections. Meter should show OL

(blocking).

No

Shut down vehicle and restart engine. Does alternator function normally after restart?

Yes

No

Regulator responded to overvoltage condition.

Go to Chart 1 on page 4 to troubleshoot OVCO.

Figure 4 – Alternator-to-Regulator

4-Socket Harness Plug

SOCKET

CONNECTIONS

A

F–

B

Phase Signal AC

C

B–

D

28 V B+

With key on, engine running: Test for battery voltage between IGN terminal on regulator and alternator B–

terminal. Does 28 V battery voltage exist?

Yes

No

With key off, engine off: Remove alternator-to-regulator 4-pin harness from regulator. Test for battery voltage

across sockets D and C in harness plug. Does 28 V battery voltage exist?

Alternator is defective.

Alternator is defective.

Yes

Connect jumper wire from socket A in regulator harness plug to B– terminal

on alternator. Spark will occur. Touch steel tool to shaft to detect significant

magnetism. Is shaft magnetized?

No

Repair vehicle ignition circuit wiring as necessary. Continue test.

Yes

No

Section D: On-Vehicle No 28 V Output Troubleshooting

Alternator is defective.

Regulator is defective.