C.E. Niehoff & Co. C714 Alternator Retrofit/Upgrade Installation User Manual

C714 alternator, Retrofit/upgrade installation instructions

II0152A

Page 1 of 2

C714 Alternator

Retrofit/Upgrade Installation Instructions

This symbol is used to indicate presence

of hazards that can cause minor property

damage.

This symbol indicates special instructions

on installation, operation or maintenance

that are important but not related to

personal injury hazards.

CAUTION

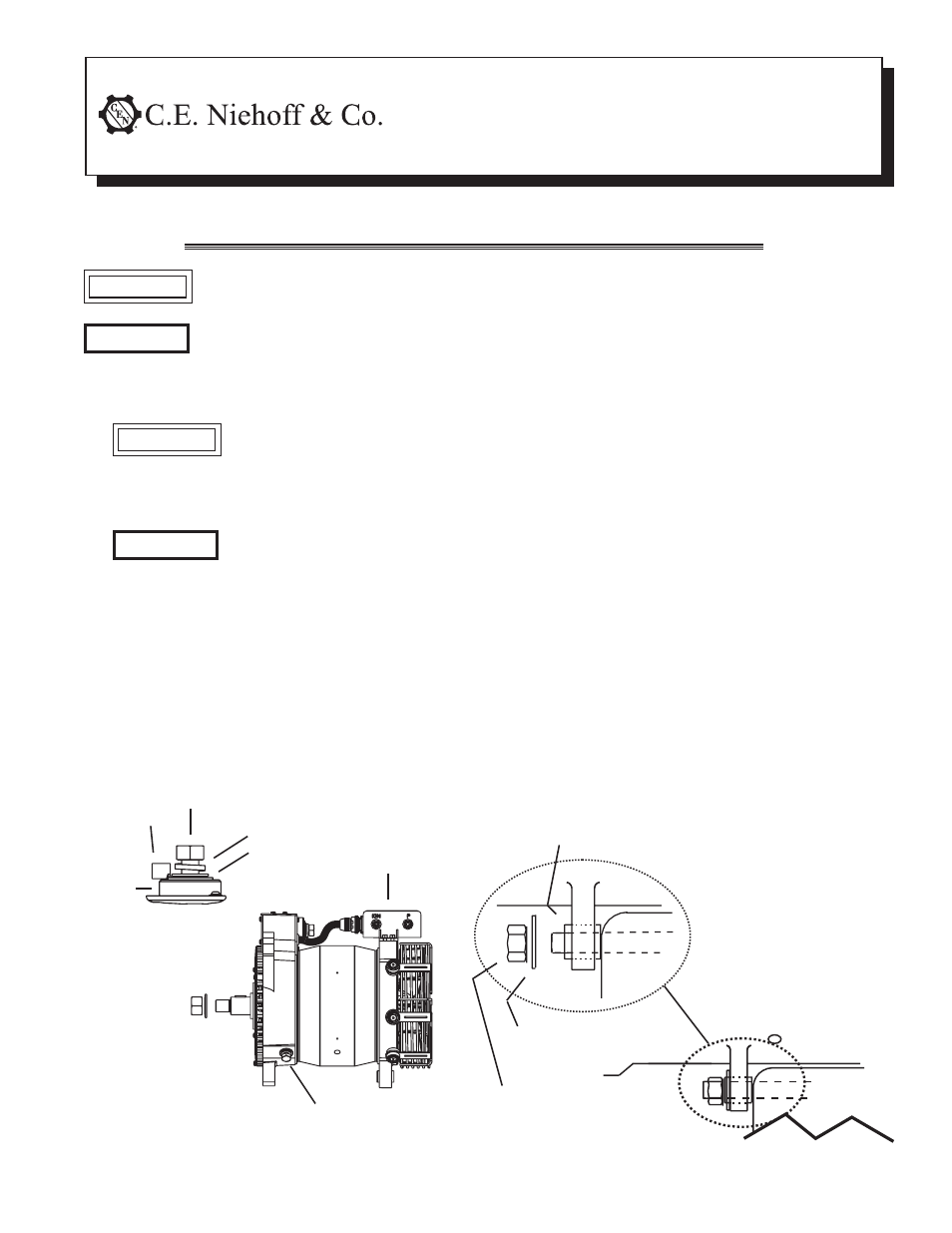

1. Install alternator as shown in Figure 1:

Slip bushing located in rear mounting

foot must be securely tightened

against alternator mounting bracket

on engine. Failure to do so can result

in broken mounting feet or broken

upper mounting bracket.

On some applications, when replacing

C712 or similar unit with C714, the

installation may require some modi-

fications to existing mounting to

accommodate new C714 alternator.

CAUTION

NOTICE

NOTICE

When replacing an existing A1-704, C711, or C712 alternator, several modifications to existing installation are required,

including replacing the pulley and regulator. READ AND FOLLOW ALL INSTRUCTIONS BELOW CAREFULLY.

a. Use hardened washers between aluminum

surfaces and bolt heads and nuts.

b. Units are shipped with shaft collar, Belleville

washer, and nut installed. Remove and discard

shaft collar.

• When replacing C714: Install existing pulley

and furnished Belleville washer. Torque fur-

nished hardware to 163 Nm/120 lb. ft.

• When replacing A1-704, C711, or C712:

Replace existing pulley with one sized

appropriately for C714 shaft and application.

Contact CEN Aftermarket Sales Department

for pulley sizing.

Figure 1—C714 Alternator Installation Details

Hardened washer

M12/0.50 Locknut –

torque to

88 Nm/65 lb. ft.

Slip bushing must be tightened against

bracket — see “CAUTION” above

Bracket

on engine

B– terminal bolt M10 x 1.5 (2 places)–

torque to 15 Nm/11 lb. ft.

M12 x1.75 bolt –

torque to 32 Nm/24 lb. ft.

Washer

Battery

output

cable

terminal

Lock washer

Insulator

Alternator B+

Terminal Stud

A2-155

Regulator