Ii72f page 2 of 2 – C.E. Niehoff & Co. C701etc/C703etc Alternator Retrofit/Upgrade Installation User Manual

Page 2

II72F

Page 2 of 2

C. E. Niehoff & Co. • 2021 Lee Street • Evanston, IL 60202 Tech Services Hotline 800-643-4633

CAUTION

9. Replace alternator drive belt if damaged or worn.

Install alternator drive belt and secure belt tension

bracket assembly. Loop alternator drive belt over

pulleys and align belt with polyvee grooves.

Make sure pulley ratio will not overspeed

alternator.

10. Belt tension guidelines shown below are a starting

point for manual and automatic belt tensioners.

•

K-section pulley: 8 grooves minimum, 10 grooves

preferred.

•

Belt wrap: 180 degree nominal. Less wrap

requires a pulley with more grooves and more

belt tension.

•

Belt tension: 80 lbs to 120 lbs nominal. More

pulley grooves permit lower belt tension.

For further questions, please contact drive belt

manufacturer.

Both too low and too high belt tension

causes premature bearing failure. Too

low belt tension causes belt slip, pulley

heating, bearing heating, and ultimately

bearing failure. Too high belt tension

increases bearing fatigue, resulting in

bearing failure.

11. Modify electrical connections to disable existing

regulator:

•

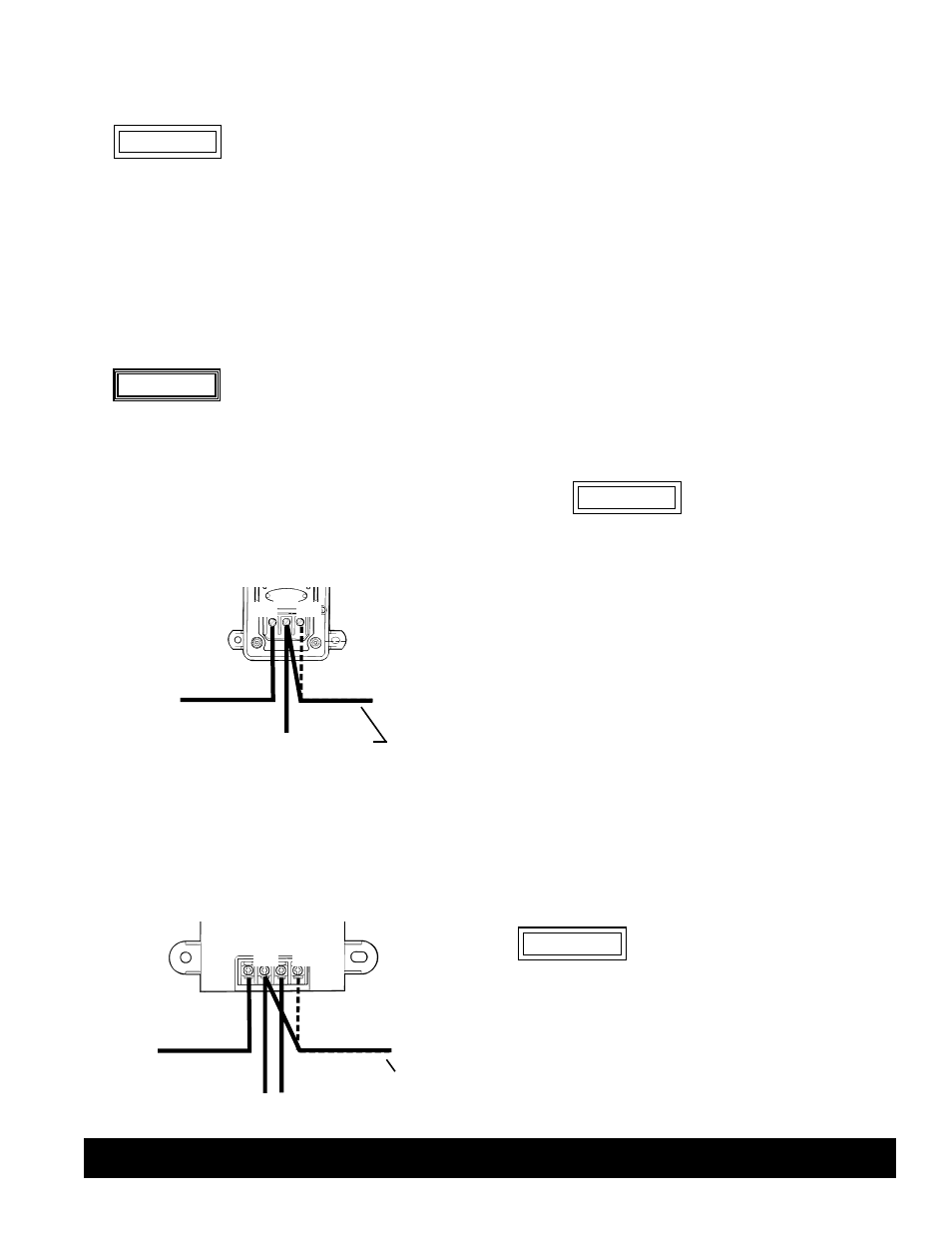

50-RD regulator – see Figure 2. Disconnect POS

lead at POS terminal on regulator and reconnect

to FLD terminal on regulator. Torque #10-24

screw to 2.3 Nm/20 lb. in.

CAUTION

Figure 2 – 50-RD Regulator Modification

Reroute this lead from POS to FLD

POS

FLD

NEG

Figure 3 – 50-VR Regulator Modification

Reroute this lead

from IGN to FLD (see NOTE above)

IGN

BAT

GND

FLD

•

50-VR regulator (refer to NOTE below) – see

Figure 3. Disconnect IGN lead at IGN terminal

on regulator and reconnect to FLD terminal on

regulator. Torque screw to 1.4 – 1.7 Nm/

12 – 15 lb. in.

NOTE: For 50-VR regulators with Deutsch connec-

tor, use CEN A9-940 wiring adaptor to jump field

and ignition wires.

CAUTION

12. Make electrical connections to CEN regulator:

a. Make sure alternator-to-regulator harness plug is

secure in regulator receptacle.

b. Connect FLD lead from existing regulator to IGN

terminal on regulator, using proper ring terminal.

Torque #10-24 terminal nut to 3.4 Nm/30 lb. in.

Torque M5 terminal nut to 4.5 Nm/40 lb. in.

c. Connect P terminal to tachometer or relay lead

from vehicle. P terminal taps AC voltage, typically

half the charge voltage. Use proper ring terminal.

Torque 1/4-20 terminal nut to 3.4 Nm/30 lb. in.

Torque M6 terminal nut to 4.5 Nm/40 lb. in.

d. D+ terminal provides 28 VDC sense voltage to

multiplex controller. When connecting D+

terminal to controller through a relay, the relay

coil must be diode protected and rated for proper

voltage. Use proper ring terminal. Torque 1/4-20

terminal nut to 3.4 Nm/30 lb. in. Torque M6

terminal nut to 4.5 Nm/40 lb. in.

13. Alternator electrical connections:

a. Replace battery positive cable if damaged or worn.

Connect battery positive cable from vehicle to

alternator B+ terminal. Torque B+ terminal on

alternator to 30 Nm/22 lb. ft. Torque cable clamp

hardware to 10 Nm/90 lb. in.

B+ cable must be supported by cable

clamp within 12’’ of B+ output termi-

nal to avoid premature failure of B+

output terminal. CEN recommends

using cable clamp attached to

alternator anti-drive end housing

for support.

b. Replace ground cable if damaged or worn.

Connect ground cable from vehicle to alternator

B– terminal. Torque B– terminal on alternator

to 15 Nm/11 lb. ft.

14. Alternator output test (conduct test with fully charged

batteries):

a. Turn on 28-volt battery system and start engine.

b. Turn on all vehicle loads, including interior/exte-

rior lights and air conditioning.

c. Measure voltage at alternator. Voltage reading

should be 27.6 – 28.0 V on low setting of regula-

tor and 28.5 – 29.0 V on high setting. See CEN

Troubleshooting Guides for further information.

d. Check battery cable voltage drop. There should be

no more than 0.4 V drop on each leg from alter-

nator to battery.

e. Road test vehicle for about 20 minutes.

f. Following road test, repeat output test.

Regulators used with these alternators feature

overvoltage cutout (OVCO), which disables

alternator output in an overvoltage condition.

Restarting engine resets OVCO circuit. When

an overvoltage condition is no longer present,

alternator and regulator should operate

normally. Should a no-output condition occur,

follow above reset procedure to determine if

OVCO trip is the cause.

WARNING