DE-STA-CO PN500 User Manual

Page 21

19

SECTION 5: Adjustments

As noted in the introduction, the Roller Gear Drive is a solid mechanical, backlash-free mechanism.

There are no adjustments required on the Indexer during installation unless it is furnished with a torque

limiting device or a motor drive package equipped with speed control. After the Indexer has been

installed and set up with the users’ load in place it will be necessary to check these items for proper

adjustment & settings.

NOTE: Drive should be in center of dwell and dowel pinned to base before installing accessories,

as previously mentioned in 4.1.1 and 4.1.5.4.

5.1.

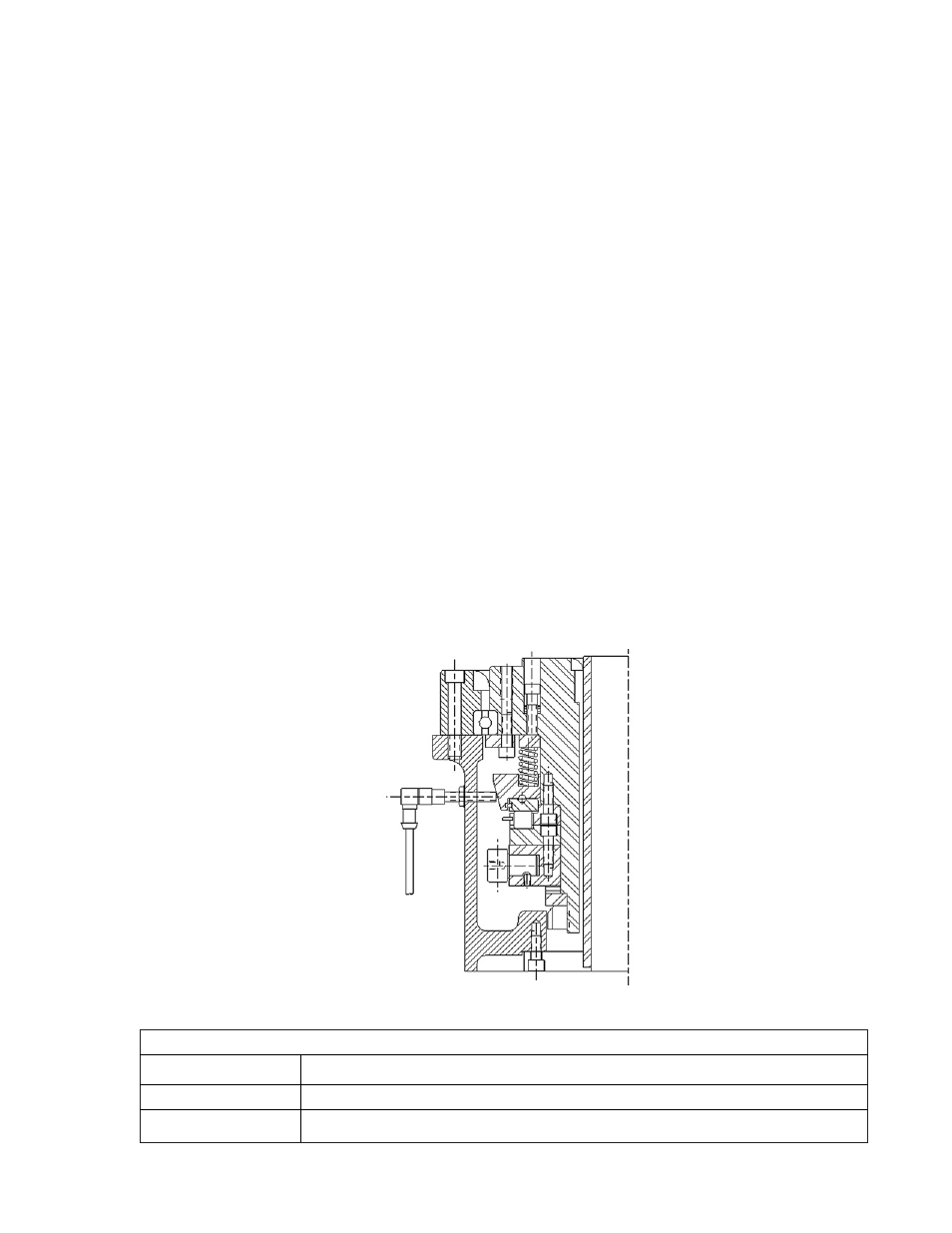

Internal Torque Limiters – ED250, PN400 and PN500

NOTE:

1.

Drive should be in center of dwell and dowel pinned to base before

installing accessories.

2.

Customer’s dial must have access holes to adjusting screws.

3.

Torque Limiter comes in three available ranges, as shown below.

Maximum torque for range ordered is stamped on face of output shaft.

5.1.1. To adjust clutch to final required setting after installing load, turn the (3) torque

adjusting screws using a .312” Allen wrench, evenly in 3 turn increments. Turn

clockwise to increase torque and counterclockwise to decrease torque.

5.1.2. Clutch proximity switch with 2-meter cable must be adjusted for proper operation.

PN500 INTERNAL CLUTCH TORQUE RANGE OPTIONS

HIGH RANGE

7,000 to 14,000 IN-LBS approx. adjustment range (3,300 IN-LBS per turn)

MED RANGE

5,500 to 11,000 IN-LBS approx. adjustment range (2,450 IN-LBS per turn)

LOW RANGE

3,600 to 7,350 IN-LBS approx. adjustment range (1,650 IN-LBS per turn)

FIGURE 12