DE-STA-CO Revised Cam Follower Installation User Manual

Important, Revised cam follower installation procedure

Industrial Motion Control, LLC (CAMCO) 1444 S. Wolf Rd., Wheeling, IL 60090-6599

IMPORTANT!!!

Revised Cam Follower Installation Procedure

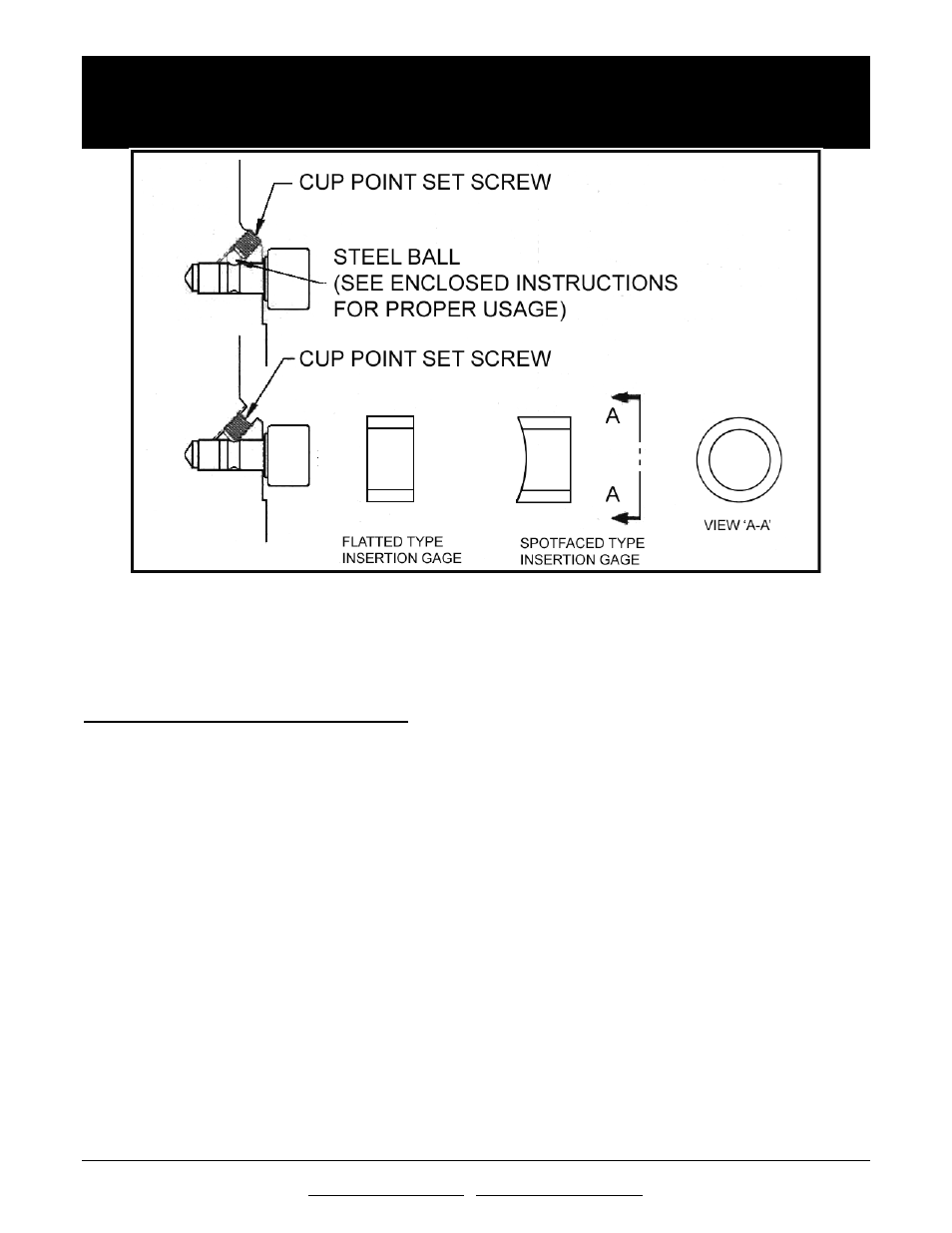

The H9 thru H32 (.287” thru 1.00” diameter) Cam Followers require a Steel Ball/Set Screw and

an insertion gage for installation. The steel ball/set screw is used to anchor the cam followers

to the follower wheel and the insertion gage kit is used to insure proper installation. The new

cam followers need to be pressed onto the follower wheel to the position prescribed by the

gage (if they are pressed in too far, the will not turn freely).

Cam Follower Installation Procedure

1. Obtain spare parts kit, cam followers and insertion gage kit.

2. Select proper insertion gage. The spot-faced type gage should be used if the cam follower

mounting surface is spot-faced. If no spot face is present, the flatted type gage should be

used (see gage illustration, above).

3. Place insertion gage around the outer diameter of the cam follower while pressing onto the

follower wheel.

4. Refer to the following chart to determine if the steel ball and set screw or the set screw

only* should be used for anchoring the cam follower. The anchoring hardware may not

always align exactly with the groove on the cam follower but it will always align within an

acceptable range. The cup point style set screw is always required.

* If steel balls and set screws were supplied with the original unit, continue using steel balls and set screws (reuse

original set or use set provided in the spare parts kit).