Eddy current inspection, Eddy current technology, Benefits of eddy currents – Atec Panametrics-Olympus-Omniscan-MX User Manual

Page 8: Eddy current probes

www.olympus-ims.com

8

Eddy Current Inspection

Eddy Current Technology

Eddy current testing (ECT) is a method for

the inspection of metallic parts. The probe,

excited with an alternating current, induces

an eddy current in the part being inspected.

Any discontinuities or material property

variations that change the eddy current flow

in the part are detected by the probe as a

potential defect.

Over the years, probe technology and data

processing have continuously progressed

so that the eddy current technique is now

recognized to be fast, simple, and accurate.

This is why the technique is widely used in

the aerospace, automotive, petrochemical,

and power generation industries in the de-

tection of surface or near-surface defects in

materials such as aluminum, stainless steel,

copper, titanium, brass, Inconel, and even

carbon steel (surface defect only).

Benefits of Eddy Currents

Eddy currents offers the following benefits:

•

A quick, simple, and reliable inspection

technique to detect surface and near-

surface defects in conductive materials

•

Can be used to measure the electrical

conductivity of materials.

•

Measurement of nonconductive

coatings

•

Hole inspection with the use of a high-

speed rotating scanner and surface

probe

Eddy Current Probes

Olympus NDT standard eddy current

probes are available in different configura-

tions:

•

Bolt hole probes

•

Surface probes, in various shapes and

configurations

•

Low-frequency Spot and Ring probes

•

Sliding probes

•

Wheel probes

•

Conductivity probes

•

Speciality probes made for specific

applications

Reference standards with EDM notches can

be manufactured according to the applica-

tion specifications.

a

b

c

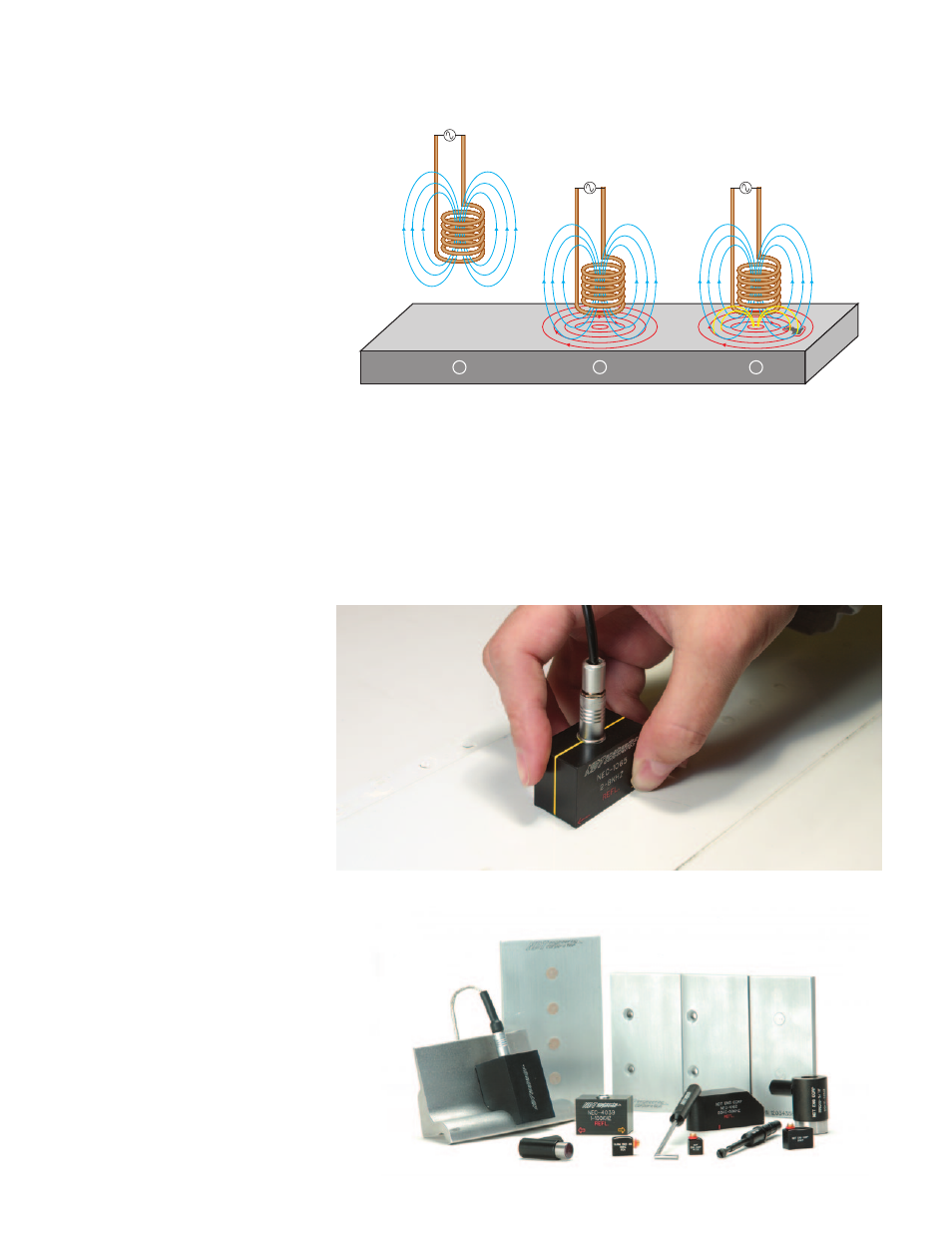

Probes used to perform eddy current inspections are made with a copper wire wound to form a coil. The coil shape can vary to

better suit specific applications.

1.

The alternating current flowing through the coil at a chosen frequency generates a

magnetic field around the coil.

2.

When the coil is placed close to an electrically conductive material, an eddy current is

induced in the material.

3.

If a flaw in the conductive material disturbs the eddy current circulation, the magnetic

coupling with the probe is changed and a defect signal can be read by measuring the

coil impedance variation.

Surface preparation is minimal. Unlike liquid penetrant or magnetic particle inspection, it is unnecessary to remove the paint from

the surface to inspect the parts.