Ultrasound inspection, Time-of-flight diffraction testing, Tofd and pulse-echo testing – Atec Panametrics-Olympus-Omniscan-MX User Manual

Page 4: Degree testing (corrosion and composite), Ultrasound transducers

www.olympus-ims.com

Ultrasound Inspection

4

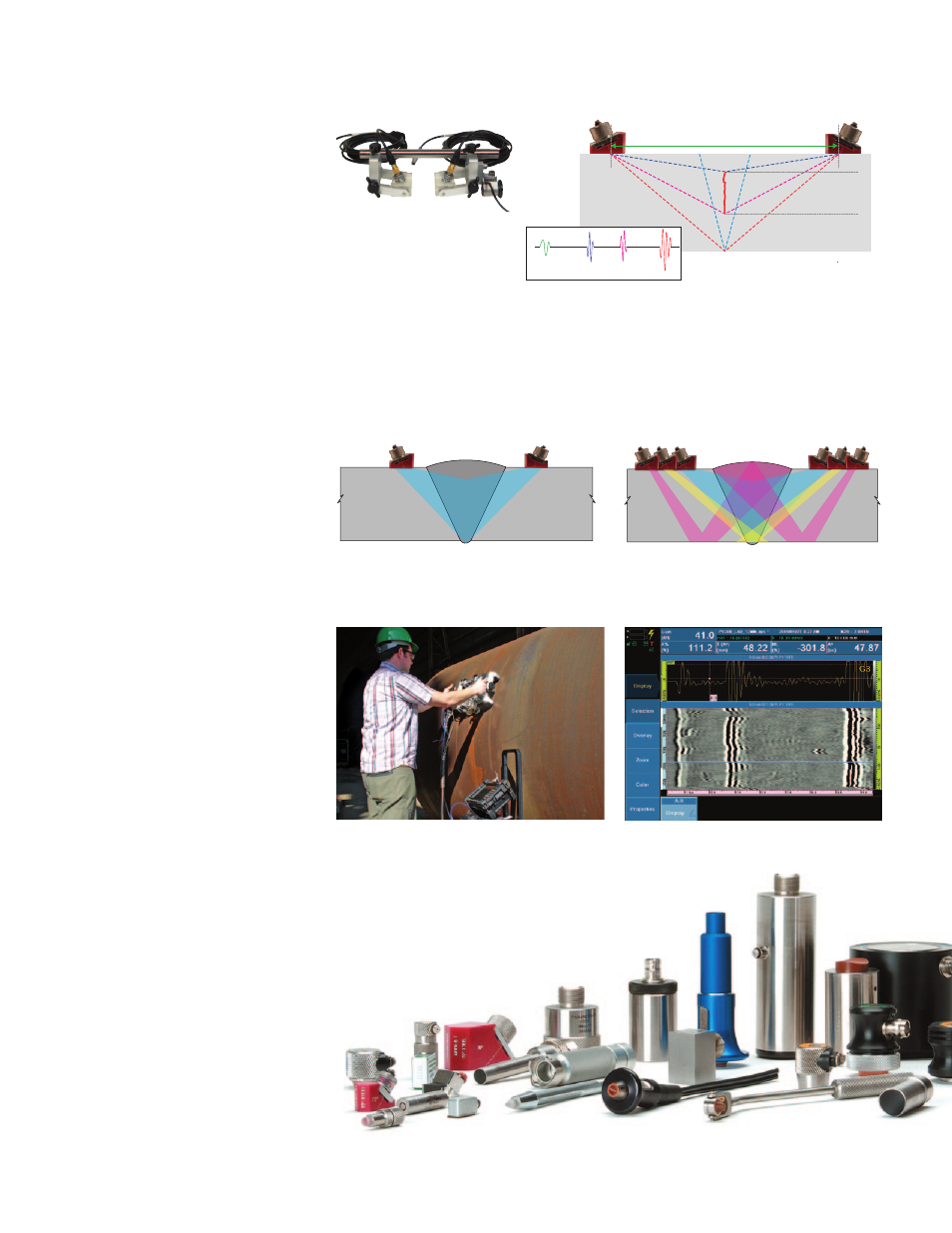

General view of TOFD setup for linear weld inspection showing

lateral wave, backwall echo, and diffracted signals on the A-scan.

Transmitter

Receiver

Lower tip

Upper tip

Backwall (+)

Lower tip (+)

Upper tip (+)

Lateral waves (+)

Lateral waves

Backwall reflection

Transmitter

Receiver

Lower tip

Upper tip

Backwall (+)

Lower tip (+)

Upper tip (+)

Lateral waves (+)

Lateral waves

Backwall reflection

The TOFD hand scanner is a small, light-

weight, efficient, low-cost, and versatile

weld inspection solution.

It can accommodate a full range of probes

and wedges, including the CentraScan

™

composite product line.

TOFD

Transmit

60º SW

PE

45º SW

PE

45º SW

PE

60º SW

PE

TOFD

Receive

Weld inspection using TOFD.

Weld inspection using combined TOFD and pulse echo

(PV-100).

HSMT-Flex scanner used for TOFD applications (PV-100).

Weld inspection with TOFD.

Time-of-Flight Diffraction Testing

Time-of-flight diffraction (TOFD) is a

technique that uses two probes in pitch-

catch mode. TOFD detects and records

signals diffracted from defect tips allowing

both detection and sizing. The TOFD data

is displayed in a grayscale B-scan view.

TOFD offers wide coverage and amplitude-

independent sizing complying with the

ASME-2235 code.

•

One-line scan for full-volume inspection

•

Setup independent of weld configuration

•

Very sensitive to all kinds of defects and

unaffected by defect orientation

TOFD and Pulse-Echo Testing

While TOFD is a very powerful and ef-

ficient technique, its coverage is limited as

a result of two inspection dead zones: one

dead zone is near the surface, the other is

at the backwall.

The OmniScan

®

UT allows inspections that

simultaneously combine TOFD with con-

ventional pulse echo. Pulse echo comple-

ments TOFD, covering the dead zones.

•

TOFD inspection

•

45º pulse echo for weld cap inspection

on either side of the weld

•

60º pulse echo for weld root inspection

on either side of the weld

0-Degree Testing

(Corrosion and Composite)

0-degree testing measures the time-of-flight

and amplitude of ultrasonic echoes reflect-

ing from the part into gates in order to

detect and measure defects.

•

C-scan imaging

•

Full A-scan recording with C-scan

postprocessing

Ultrasound Transducers

Olympus NDT offers a selection of thou-

sands of transducers in standard frequen-

cies, element diameters, and connector

styles.

•

Contact and immersion transducers

•

Dual transducers

•

Angle-beam transducers and wedges

•

Replaceable delay line transducers

•

Protected face transducers

•

Normal incidence shear-wave

transducers