Elmo Rietschle G-BH1e User Manual

Page 38

610.44521.40.000

38 / 52

© Gardner Denver Deutschland GmbH

Commissioning

5.3

Start-up of the pump-motor unit

The description of how to change pre-set parameters using the hand-held keypad starts on page 34.

NOTE

When no setpoint has been entered, the drive rotates with the minimum frequency set under

C0010!

The setpoint offset set under C0140 is stored and will be active at each switch−on.

The setpoint offset set under C0140 has an additive effect on all other setpoints!

This effect can be used, for example, to set speeds between fixed speeds:

–

Fixed speed via terminal = 67 Hz (4000/min)

–

C0140 = -7 Hz

–

Resulting speed = 60 Hz (3600/min)

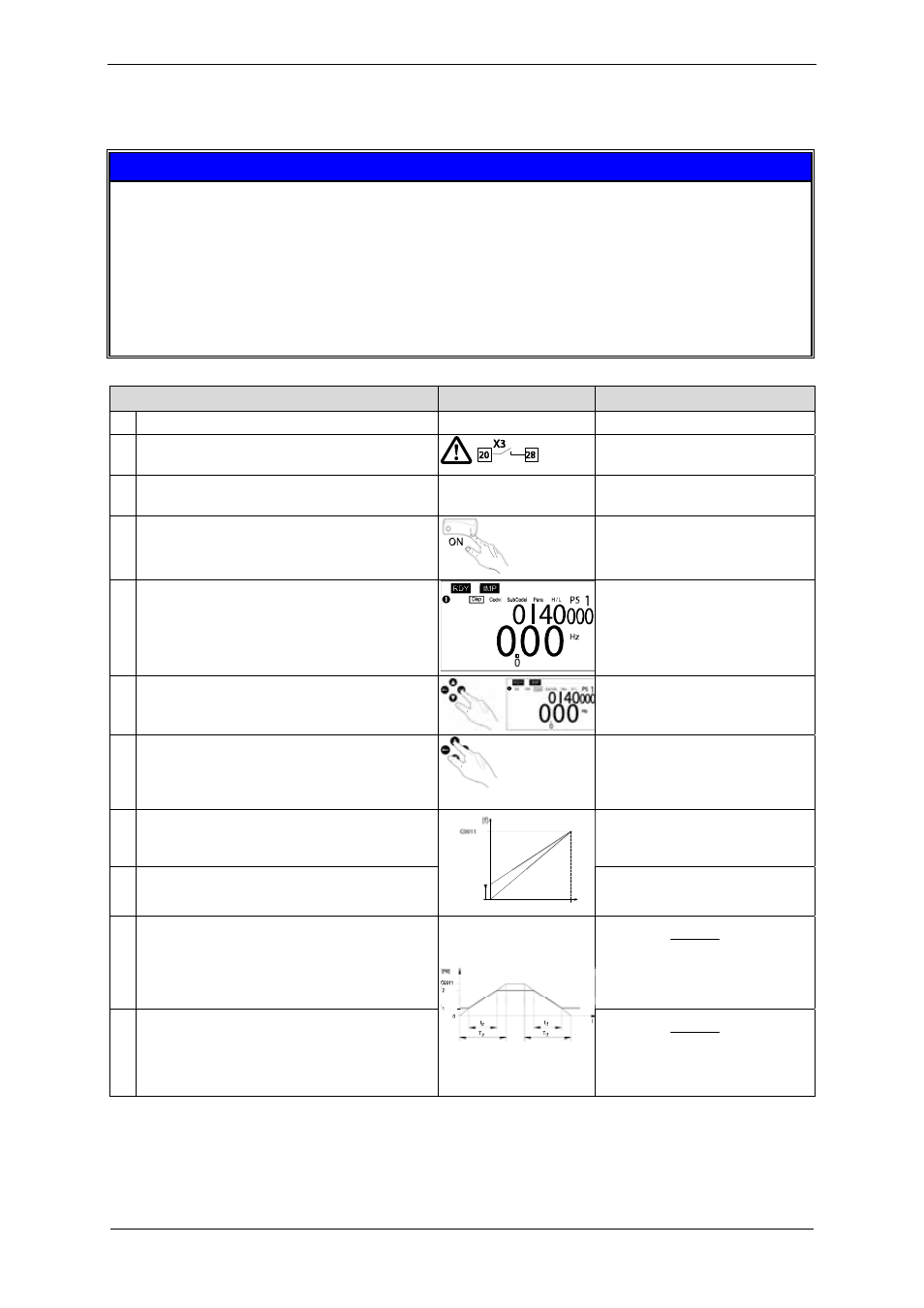

Switch-on sequence

Note

1. Connect

keypad.

2. Ensure that controller inhibit is active after

mains connection.

misc00

Terminal X3/28 = LOW

3. Open the shut−off device in the inlet line or in

the pressure line..

4. Switch on the mains.

misc002

5. The keypad is in “Disp” mode after approx. 2

s and indicates the setpoint offset (C0140).

Set

6. Change to the mode with in order to

set drive parameters.

0I40 is blinking in the display

.

7. Press

.

Thus, you skip the display codes

for output frequency (C0050),

motor voltage (C0052) and

apparent motor current (C0054).

8. Set the minimum output frequency (C0010).

Default setting: 10.00 Hz (600/min)

After controller enabling, the

motor at least rotates with the

frequency set under C0010!

9. Set the maximum output frequency (C0011).

Default setting: 86.00 Hz (3000/min)

[f]

C0011

0 %

100%

C0010

10. Set acceleration time Tir (C0012).

Default setting:

10 00 s: frequency inverters up to 5 kW

25.00 s: frequency inverter 7.5 kW

1

0011

*

2

f

f

C

t

T

ir

ir

t

ir

= desired acceleration time

11. Set deceleration timeT

if

on (C0013).

Default setting:

10 00 s: frequency inverters up to 5 5 kW

20.00 s: frequency inverter 7.5 kW

1

0011

*

2

f

f

C

t

T

ir

ir

t

if

= desired deceleration time