3 transport and handling, Warning, Caution – Elmo Rietschle G-BH1e User Manual

Page 14

610.44521.40.000

14 / 52

© Gardner Denver Deutschland GmbH

Transport and handling

3 Transport and handling

WARNING

Tipping or falling can lead to crushing,

broken bones etc.!

Sharp edges can cause cuts!

Wear personal safety equipment (safety

gloves, safety shoes and safety helmet)

during transport!

WARNING

Danger from lifting heavy loads!

Manual handling of the pump−motor unit is only

permitted within the following limits:

max. 30 kg [max. 66 lbs] for men

max. 10 kg [max. 22 lbs] for women

max. 5 kg [max. 11 lbs] for pregnant women

For weights above the given values use

suitable lifting appliances and handling

equipment!

Weight of the pump−motor units: ( 11)

WARNING

Danger from tipping or falling loads!

Prior to transport and handling make sure

that all components are securely assembled

and secure or remove all components the

fasteners of which have been loosened!

When transporting with lifting equipment,

observe the following basic rules:

–

The lifting capacity of lifting equipment

and lifting gear must be at least equal to

the unit’s weight. For the weight of the

pump−motor units see:: ( 11)

–

The pump−motor unit must be secured

so that it cannot tip or fall.

–

Do not stand or walk under suspended

loads!

3.1 Transport

devices

All pump−motor units with a weight of more than

30 kg are equipped with an eye bolt at the side

channel housing.

The crane hook can be hooked directly into the

eye bolt.

Alternatively the pump−motor units can be

transported with lifting belts.

WARNING

Danger from tipping or falling loads!

Place the lifting belts under the side channel

housing and under the motor.

Attach the lifting belts in such a way that the

suspending pump−motor unit is balanced

and cannot slip out of the lifting belts.

3.2 Transport

types

CAUTION

Pump−motor unit damage caused by

improper manual handling!

Do not carry the pump−motor unit by holding

it at the frequency inverter!

Avoid heavy impact loads during transport.

CAUTION

Pump−motor unit damage caused by

improper transport with lifting appliances!

Do not attach the lifting appliances to the

frequency inverter!

The eye bolt at the side channel housing

must

–

be screwed tightly.

–

be exactly in axial direction of the

pump−motor unit. Lay shims under the

eye bolt if necessary.

Loads laterally to the ring level are not

permissible.

Avoid heavy impact loads during transport.

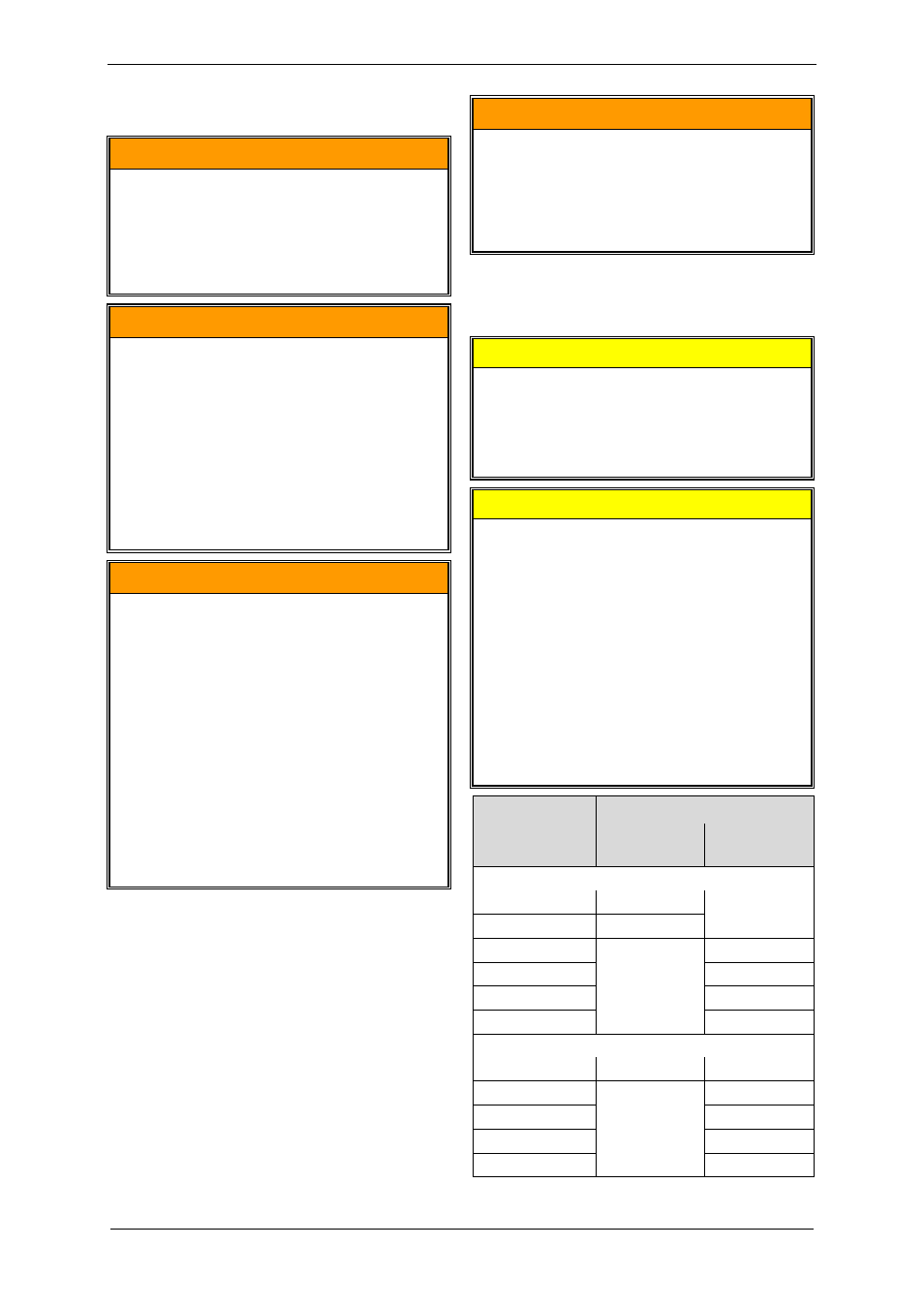

Type of transport

Type

manually

with lifting

appl.

Single−impeller design

2BH1400-7.N1. X

2BH1400-7.N2. X

2BH1500-7.N3. X

2BH1600-7.N3. X

2BH180.-7.N0. X

2BH180.-7.N1.

X

Two−impeller design

2BH1310-7.N2. X

2BH1410-7.N4. X

2BH1510-7.N5. X

2BH1610-7.N3. X

2BH1610-7.N4.

X