Elmo Rietschle G-BH1e User Manual

Page 24

610.44521.40.000

24 / 52

© Gardner Denver Deutschland GmbH

Installation

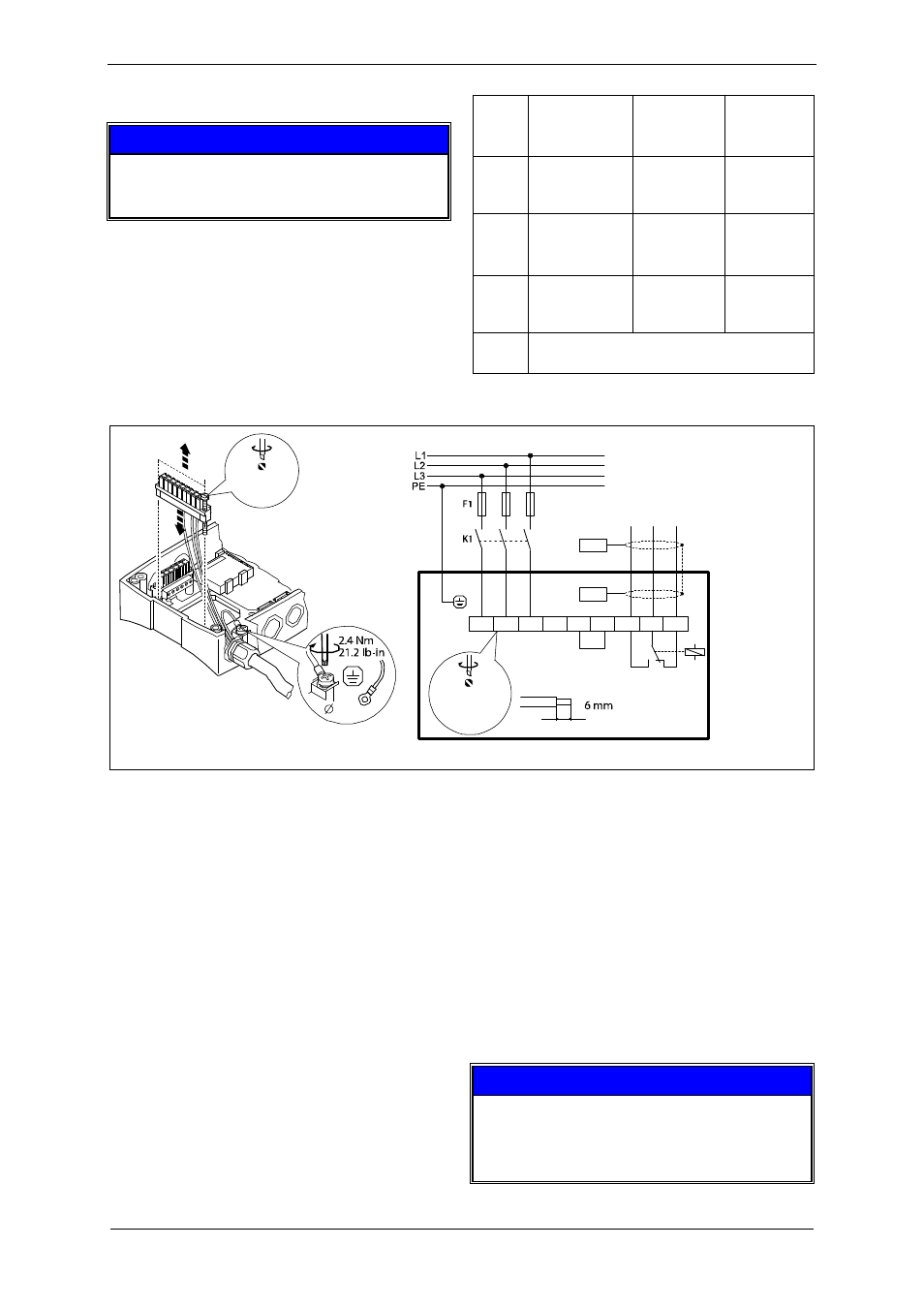

Relay data

NOTE

The service life of the relay depends on the

type of load (ohmic, inductive or capacitive)

and the value of the switching capacity.

Technical data

AC 250 V/3 A

DC 24 V/2 A ... DC 240 V/0.22 A

Function Relay

position

switched

Displayed

message

X1/K11 Relay output

normally−close

d contact

opened TRIP

X1/K12 Relay

mid−position

contact

X1/K14 Relay output

normally−open

contact

closed TRIP

PES

HF shield termination by large−surface

connection to PE

Connection

X1

5.3 mm

3/PE AC, 320 V ... 550 V, 45 ... 65 Hz

X1 L3

L2

BR2

K14

L1

BR1

K12

BR0

K1

1

PES

PES

0.5...0.6 Nm

4.4...5.3 lb-in

1.2...1.5 Nm

10.7...13.3 lb-in

ne2bhxn231

Fig. 12: Frequency inverter 2FC4152-1NE00 ... 2FC4222-1NE00 1

connecting

1 Connecting the mains cable:

A Release two screws at terminal X1 and

remove the terminal.

B Pass the mains cable through the cable gland.

C Attach the ring cable lug ( 5.3 mm) to the PE

conductor.

D Screw the PE conductor onto the PE stud for

the mains cable:

–

observe tightening torque!

E Connect cores L1, L2 and L3 to X1 in correct

phase relation:

–

observe tightening torque!

2 Wiring the relay output (if necessary):

A Pass the cable through the cable gland.

B Connect the shield of shielded cables

according to EMC requirements ( 23).

C Connect cores to terminal X1:

–

observe terminal connection diagram and

tightening torque!

3 Re−insert terminal X1 and tighten with 2

screws:

–

observe tightening torque!

4 Connecting the control cable shield:

A Pass the control cable through the cable

gland.

B Connect the shield according to EMC

requirements ( 23).

C Control cable connection: ( 28)

5 Tighten all cable glands.

NOTE

Do not remove the jumper between terminals

BR1 and BR0!

Otherwise trouble−free functioning of the

pump−motor unit cannot be guaranteed.