Installation, Screw terminal data, Wiring – Elmo Rietschle G-BH1e User Manual

Page 29

© Gardner Denver Deutschland GmbH

29 / 52

610.44521.40.000

Installation

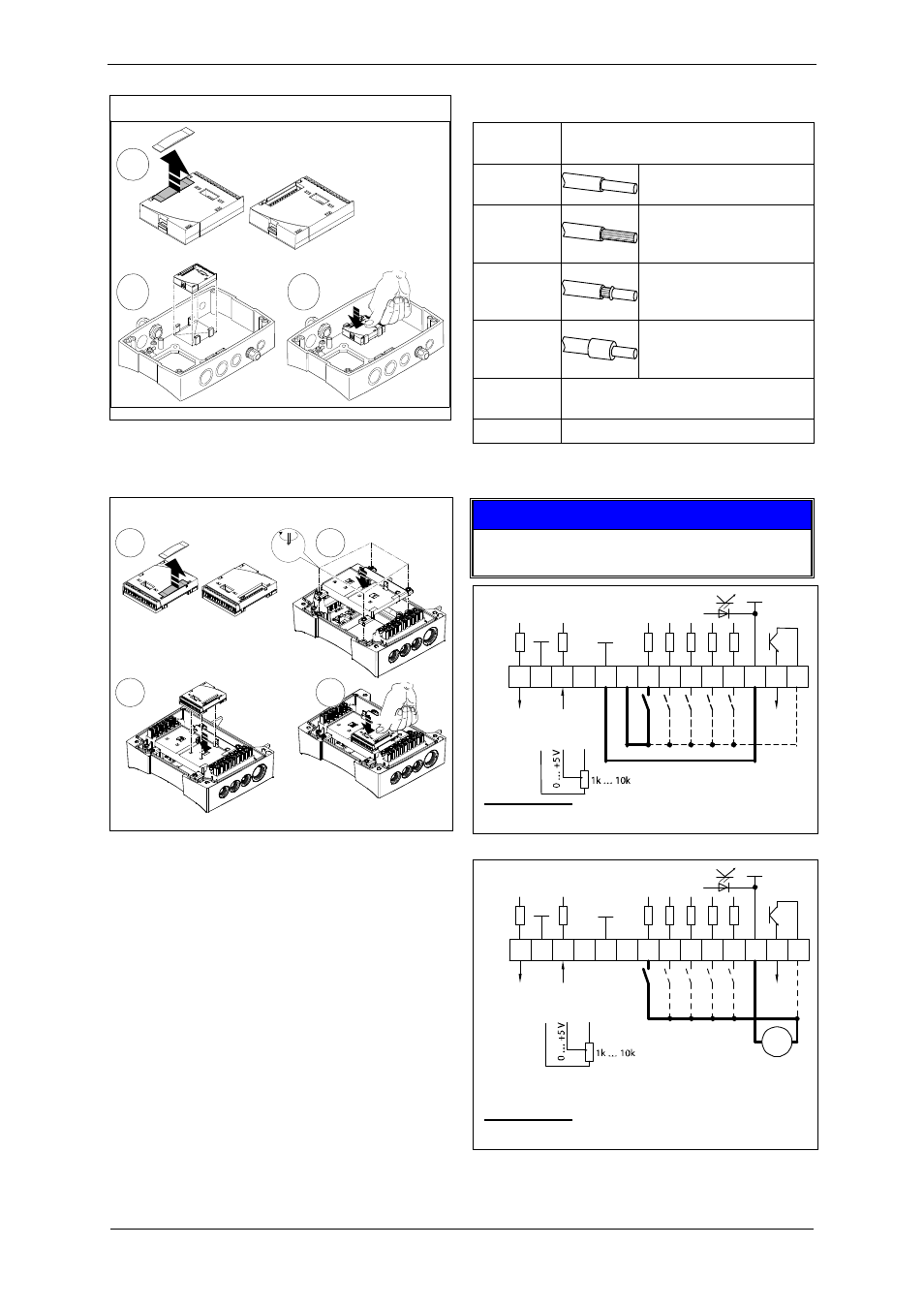

2FC4152-1NE00 … 2FC4222-1NE00

ne2bhxn147

Fig. 16: Control terminal module installation in

frequency inverters 2FC4152−1NE00 and

2FC4222−1NE00

2FC4302-1NE00 … 2FC4752-1NE00

1

3

2

CLACK

4

1.1 Nm

9.7 lb-in

ne2bhxn447

Fig. 17: Control terminal module installation in

frequency inverters 2FC4302−1NE00 ...

2FC4752−1NE00

Screw terminal data

Electrical

connections

Terminal strip with screw connection

Possible

connections

rigid:

1,5 mm

2

(AWG 16)

flexible:

without wire end ferrule

1,0 mm

2

(AWG 18)

without wire end ferrule,

without plastic sleeve

0,5 mm

2

(AWG 20)

with wire end ferrule, with

plastic sleeve

0,5 mm

2

(AWG 20)

Tightening

torque

0,22 … 0,25 Nm (1,9 … 2,2 lb-in)

Bare end

5 mm

Wiring

NOTE

Always shield control cables in order to avoid

interference injections!

GND1

62

8

9

20 28 E1 E2 E3 E4 39 A1 59

X3

GND1

GND2

+5V

+20V

8

9

7

AIN1

AOUT1

DIGOUT1

7

7

Required minimum wiring for operation

n_e2fcx072

Fig. 18: Supply via the internal voltage source (X3/20)

GND2

8

9

7

GND1

62 7

8

9

20 28 E1 E2 E3 E4 39 A1 59

X3

7

GND1

+5V

+20V

+

_

AIN1

AOUT1

DIGOUT1

24 V ext.

(+12 V DC - 0%

...

+30 V DC + 0%

max. 120 mA

Required minimum wiring for operation

n_e2fcx073

Fig. 19: Supply via an external voltage source

C

L

A

CK

3

2

1