800gs, Deluge valve – Cla-Val 834-05 User Manual

Page 7

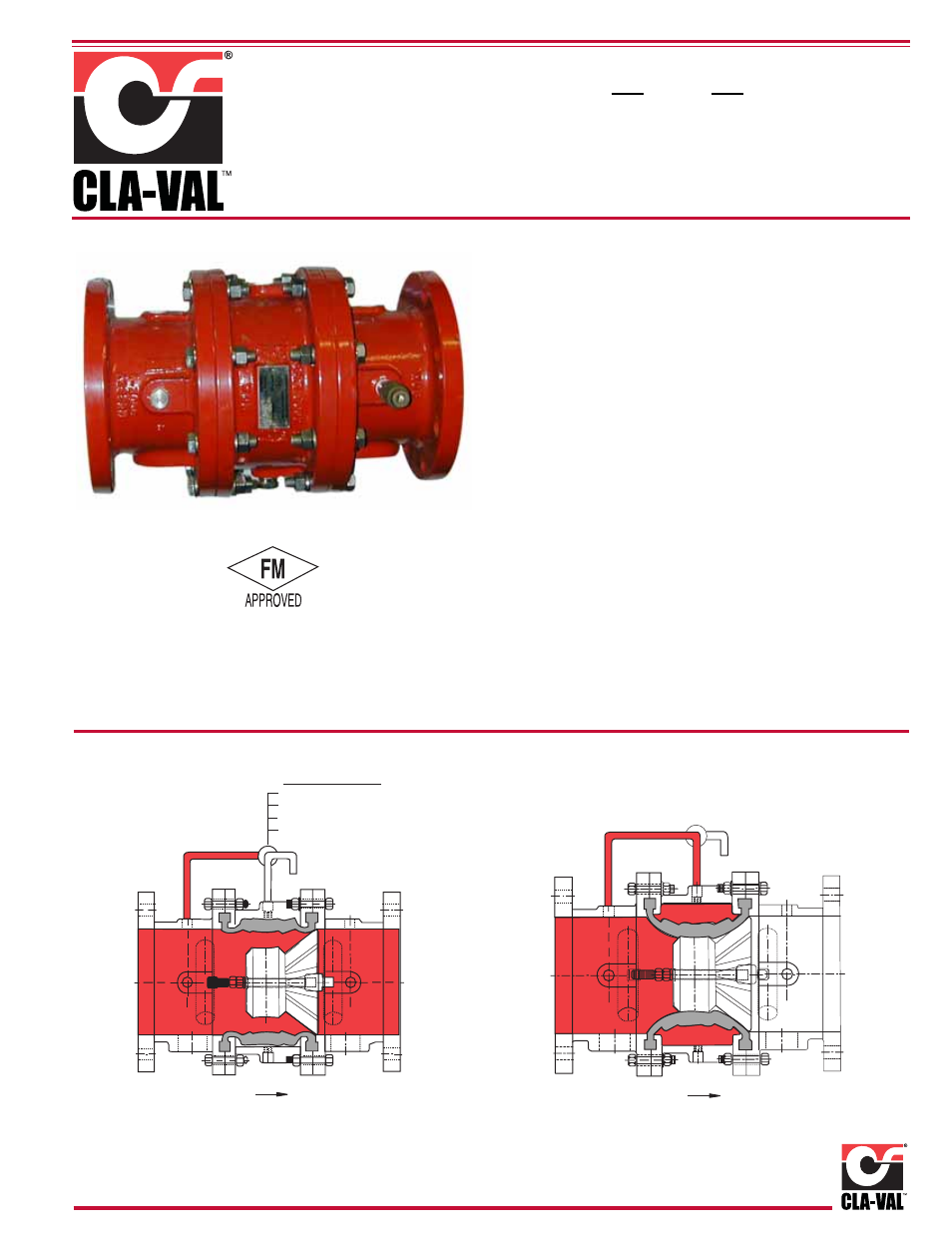

Control Options

Electric Operation

Pneumatic Operation

Hydraulic Operation

Manual Operation

FLOW

FLOW

• 3-Year Warranty

• Low Head Loss

• Cast Steel Construction

• Stainless Steel Pilot and Tubing

• Stainless Steel Solenoid

• Anti-Cavitation Design

• Fusion Coated Epoxy Inside and Out

• Nickel Aluminum Bronze Construction Option (Alloy C95800)

• Duplex Stainless Steel Construction Option (Alloy 2205)

• Low Maintenance

• Simple and Reliable Operation

The Cla-Val Model 800GS Deluge Valve is a pressure operated, in-

line axial valve. A tube diaphragm actuates the valve, which is com-

prised of three major components: 1) Tube 2) Barrier and 3) Body.

There is only one moving part in the valve - the tube diaphragm.

There are no shafts, packing, stem guides or springs.

The tube diaphragm is a one piece, homogeneous nitrile rubber part

which is extremely durable. The ends of the tube are thick solid rubber,

designed to fit between mating flanges. This design eliminates the

possibility of cutting the tube diaphragm due to overtightening or pip-

ing misalignment during installation.

The tube forms a drip tight seal around the barrier when the pressure

is equalized between the valve inlet and the control chamber. When

pressure is removed from the control chamber, the valve is open. The

minimum recommended operating pressure is 40 P.S.I. of inlet pressure.

Principle of Operation

Full Open Operation

When pressure in control chamber

is relieved, the valve is open.

Tight Closing Operation

Water pressure from valve inlet is

applied to the control chamber. Valve

closes bubble tight.

Deluge Valve

800GS

MODEL

Inlet

Outlet

Inlet

Outlet

The 800GS is manufactured in materials suitable for seawater and freshwater service.

800 Series (Tubular Diaphragm Valve)