Cla-val – Cla-Val 834-05 User Manual

Page 18

MANUAL OPERATION

The Cla-Val Latching Deluge Pilot employ the "Pull-To-Reset"

concept for manual, in-service position placement. Pulling out-

ward on the knob will position the assembly to admit pilot supply

pressure into the piston chamber. An internal bore within the

stem becomes aligned with the Pilot Supply (PS) port to admit

pressure into the piston chamber.

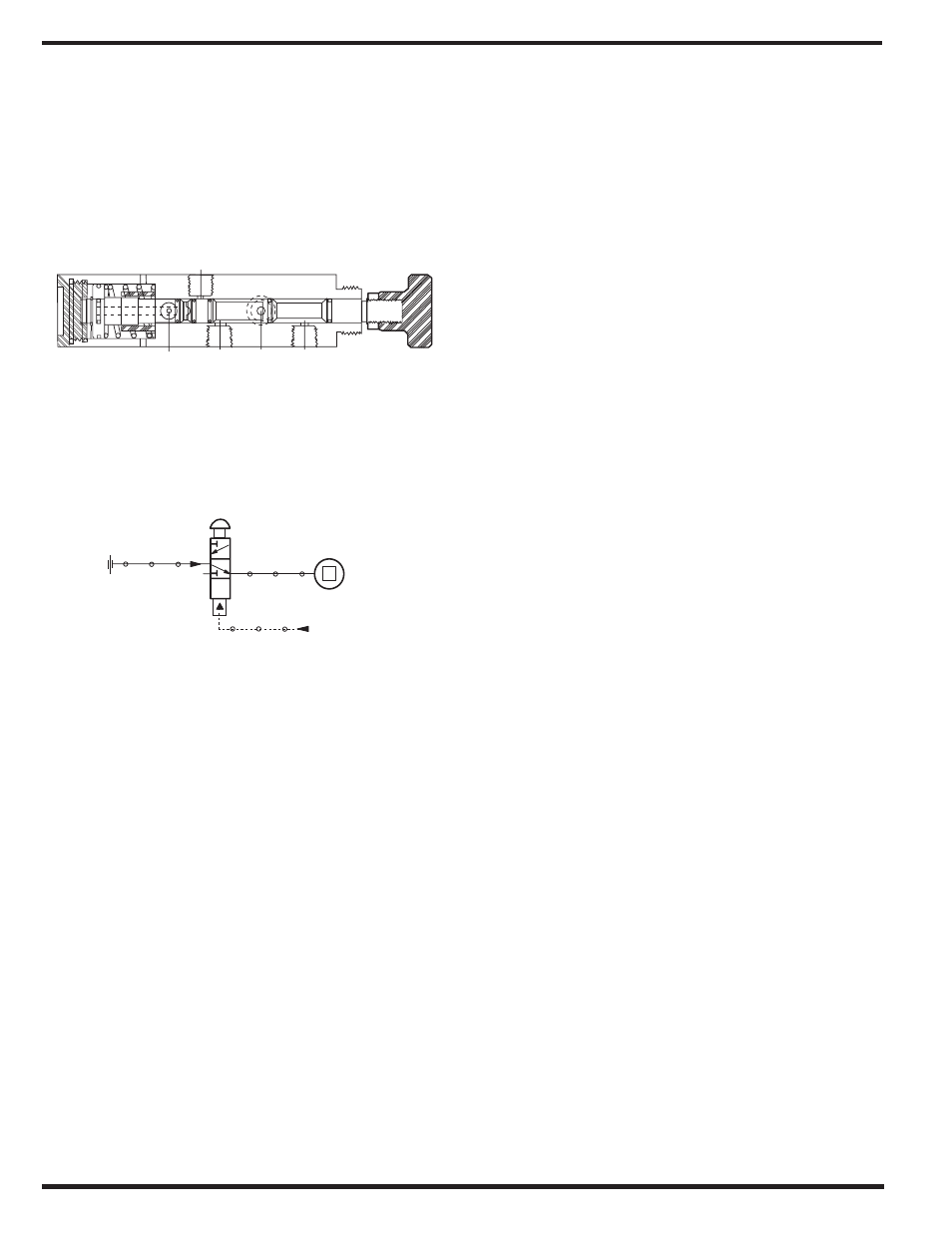

The following assembly drawing shows the assembly positioned

in a normal, in-service (actuated) set position.

As shown, the internal components are held in position by pres-

sure within the piston chamber. The flow path established

between the Inlet (IN) and Outlet (OUT) connection is maintained.

A schematic to depict the established flow path is provided.

OUT

IN

EXH

PS

V

G

EXH

PS

IN

OUT

CONTROL

PRESSURE

SOURCE

PUSH TO ACTUATE

DELUGE VALVE

CONTROL CHAMBER

STATUS:

DELUGE:

DELUGE VALVE

CLOSED

PILOT SUPPLY

PRESSURE APPLIED

PILOT STATUS: IN-SERVICE-POSITION

PILOT SUPPLY PRESSURE IS ABOVE

MINIMUM "LATCH" PRESSURE REQUIRED (20 PSI MIN.)

KNOB POSITION: OUT

Loss of pilot supply pressure or manually pushing inward on the

knob will shift the stems position. Whenever the pilot pressure

decreases sufficiently or becomes absent, the large internal

spring will force the stem assembly inward. Pressure previously

accumulated downstream of the Outlet (OUT) connection will

backbleed or exhaust through the Exhaust (EXH) port. The Inlet

(IN) will become isolated or blocked to flow. A return to the shelf

or unactuated position is denoted by the control circuits depres-

surization.

INSTALLATION

WARNING: The user of Cla-Val products must conform to all

applicable Mechanical, Piping, NFPA and other established

National Codes in the installation and operation of control valves.

Do not attempt to install or operate these devices without proper

training in the technique of working on pneumatic, fluid power

controls, systems and other devices.

Prior to the installation of the Cla-Val 150-300 Latching Deluge

Pilot, it is recommended that the 1/4" NPT male threads of the

tubing connections be carefully Teflon taped. It is also recom-

mended that a light coat of *Swak

®

(Anaerobic Pipe Thread

Sealant with TFE) be applied on the pipe threads whenever one

stainless steel component is screwed into another. The Teflon

tape and special thread sealant will prevent "galling" or seizure

and provide an excellent pressure seal.

MAINTENANCE

The only maintenance normally required is periodic inspection of

the control system to insure there is no buildup of solids that might

cause poor performance. This is usually accomplished by clean-

ing the strainer screen. Also, see pilot valve maintenance bulletin.

Scheduled maintenance is dependent upon the severity, frequency

of use and cleanliness of the control (media) source.

Established client fire and safety systems test guidelines must be

followed. NFPA 25 Standard for the Inspection, Testing and

Maintenance of Water-Based Fire Protection Systems must also

be followed.

Once the control system is properly isolated and depressurized,

the Latching Deluge Pilot can be disassembled. The piston

assembly and internal bores should be thoroughly cleaned. All

seals and spring should be replaced, whenever the control is dis-

assembled for the 5 yr. maintenance program & or as needed.

See maintenance bulletin.

A lubricant such as **Dow Corning Molykote 33 or ***Parker

Super O Lube 884-2 is recommended for maximum efficiency.

Care should be taken to lubricate the Seals and internal bores

lightly. Re-assemble the valve and function test according to facil-

ity procedures and requirements.

CAUTION: BEFORE PROCEEDING WITH THE DISASSEMBLY OF ANY CLA-VAL

PRODUCT, STRICT COMPLIANCE WITH YOUR FACILITIES ESTABLISHED

SAFETY PROCEDURE FOR ISOLATING, TESTING OR EXHAUSTING PRES-

SURE FROM A CONTROL SYSTEM OR DEVICE IS REQUIRED.

MEDIA CONTROL SYSTEMS CONTAIN HIGH LEVELS OF STORED ENERGY. DO

NOT ATTEMPT TO CONNECT, DISCONNECT OR REPAIR THESE PRODUCTS

WHENEVER A SYSTEM IS PRESSURIZED.

NOTE: ALWAYS EXHAUST THE PRESSURE FROM THE SYSTEM BEFORE PER-

FORMING ANY SERVICE WORK. FAILURE TO DO SO CAN RESULT IN SERIOUS

PERSONAL INJURY.

CLA-VAL

Copyright Cla-Val 2005 Printed in USA Specifications subject to change without notice.

P.O. Box 1325

• Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: [email protected] • Website cla-val.com

©

N-CMDL Latching Deluge Pilot (R-8/05)

SWAK

®

is a registered trademark of Swagelok Company.

SWAK

®

is available from the independent distributors of

Swagelok, and can be purchased online at

www.swagelok.com