Gas valves, Checking the input – John Wood Commercial Atmospheric Vent - AJWSM User Manual

Page 27

27

TYPICAL PILOT AND MAIN BURNER FLAMES

FIGURE 16

If the preceding burner characteristics are not evident, check

for accumulation of lint or other foreign material that restricts or

other foreign material that restricts or blocks the air openings to

the burner or heater.

NOTE: Cleaning of main burners.

1. Remove main burners from unit.

2. Check that burner venturi and ports are free of foreign

matter.

3. Clean burners with bristle brush and/or vacuum cleaner — DO

NOT distort burner ports or pilot location.

4. Reinstall burners in unit. Make sure front and rear of burners

are installed correctly in burner support brackets.

Also check for good flow of combustion and ventilating air to the

unit. Maintain a clear area around the heater at all times.

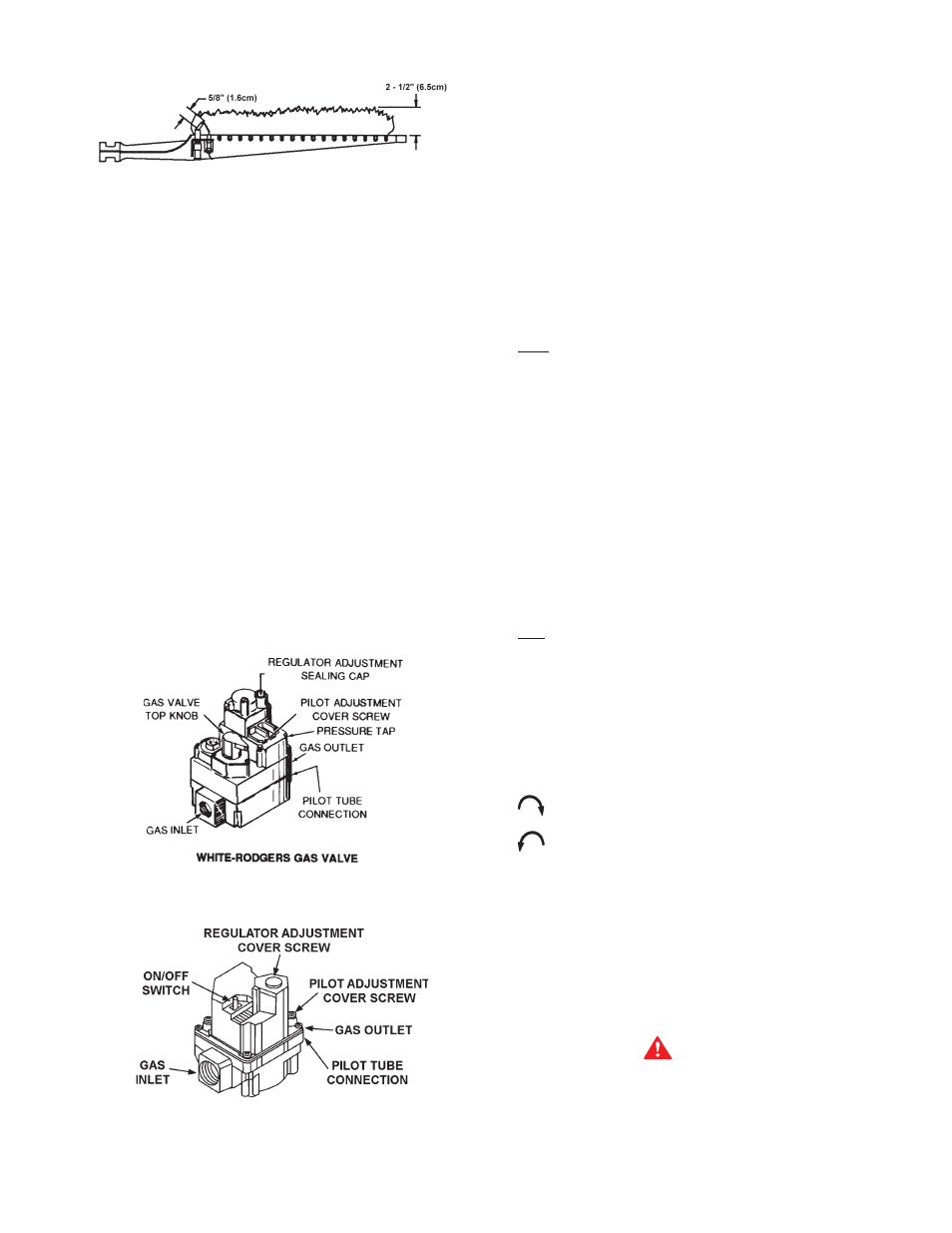

GAS VALVES

Figure 17 shows the two types of combination gas control valves

used on these heaters.

LP VALVE

NATURAL VALVE

FIGURE 17

If the gas valve becomes defective, repairs should not be

attempted. A new valve should be installed in place of the

defective one.

CHECKING THE INPUT

For appliance installation locations with elevations above 2000

feet (610 m), refer to HIGH ALTITUDE INSTALLATIONS section

of this manual for input reduction procedure.

1. Attach a pressure gauge or a manometer to the gauge port and

refer to Table 5, for correct manifold pressure.

2. Use this formula to “clock” the meter. Be sure that other gas

consuming appliances are not operating during this interval.

3600 X H = Btuh

T

T = Time in seconds to burn one cubic foot of gas.

H = Btu’s per cubic foot of gas.

Btuh = Actual heater input.

Example: (Using BTRC-199 heater)

T = 15.8 seconds

H = 1050 Btu

Btuh = ?

19.0 X 1050 = 199,000 Btuh (70.3 Kwh) (Compare with

15.9 heater model and rating)

Should it be necessary to adjust the gas pressure to the burners

to obtain the full input rate, the steps below should be followed:

3. Remove the regulator adjustment sealing cap, fig. 17, and

adjust the pressure by turning the adjusting screw with a

screwdriver.

Clockwise to increase gas pressure and input rate.

Counterclockwise to decrease gas pressure and input

rate.

4. “Clock” the meter as in step 2 above.

5. Repeat steps 3 and 4 until the specified input rate is achieved.

6. Turn the gas control knob to PILOT. Remove the pressure

gauge and replace the sealing cap and the allen wrench set

screw in the pressure tap opening.

WARNING

UNDER NO CIRCUMSTANCES SHOULD THE GAS INPUT

EXCEED THE INPUT SHOWN ON THE HEATER MODEL AND

RATING PLATE. OVERFIRING COULD RESULT IN DAMAGE

OR SOOTING OF THE HEATER.

When the heater is operating at full capacity, or full gas input, it

should consume 1 cu. ft. of gas in time indicated on Table 6.

CREATED BY NEEVIA DOCUSTAMP TRIAL VERSION (WWW.NEEVIA.COM)

CREATED BY NEEVIA DOCUSTAMP TRIAL VERSION (WWW.NEEVIA.COM)