Maintenance and storage, Updating instrument and probe firmware, General maintenance - battery compartment gasket – YSI ProODO User Manual

Page 20: Sensor maintenance - dissolved oxygen

30

31

M A I N T E N A N C E A N D S T O R A G E

This section describes the proper procedures for care, maintenance and storage

of the ProODO. The goal is to maximize their lifetime and minimize down-time

associated with improper sensor usage.

updatInG InstruMent and proBe fIrMWare

The instrument and probe’s firmware can be updated via www.ysi.com. There

you will find the new firmware files and instructions on how to update the

instrument and/or probe. There is no need to send the instrument back to the

factory for upgrades.

General MaIntenance - Battery

coMpartMent GasKet

The instrument utilizes a gasket as a seal to prevent water from entering the

battery compartment. If the gasket and sealing surfaces are not maintained

properly, it is possible that water can enter the battery compartment. This

could severely damage the battery terminals causing loss of battery power and

corrosion to the battery terminals. Therefore, when the battery compartment

lid is removed, the gasket that provides the seal should be carefully inspected for

contamination (e.g. debris, grit, etc.) and cleaned if necessary. If contamination

is evident, clean the gasket and nearby plastic parts with lens cleaning tissue or

equivalent lint-free cloth. Alcohol can be used to clean the plastic parts, but use

only water and mild detergent on the o-ring itself. Also, inspect the gasket for

nicks and imperfections.

Using alcohol on a gasket may cause a loss of

elasticity and may promote cracking.

sensor MaIntenance - dIssolVed oxyGen

CLEANING THE SENSOR CAP

The Sensor Cap should be kept clean since some types of fouling may consume

oxygen which could affect the dissolved oxygen measurements. To clean the

Sensor Cap, gently wipe away any fouling with a lens cleaning tissue that has

been moistened with water. Do not use organic solvents to clean the Sensor Cap.

Using an organic solvent to clean the Sensor Cap may cause permanent damage

to the cap. For example, alcohol will dissolve the outer paint layer and other

organic solvents will likely dissolve the dye in the cap

i

i

SENSOR CAP REPLACEMENT

The Sensor Cap should be replaced about once per year but may last longer.

It should also be replaced if it is cracked or damaged (see Troubleshooting

section for instruction on how to inspect the cap for damage). The instruction

sheet shipped with the replacement ODO sensor cap includes the calibration

coefficients specific to your sensor cap.

IMPORTANT - Be sure to save the ODO Sensor Cap instruction

sheet in case you need to reload the calibration coefficients.

The replacement ODO Sensor Cap is shipped in a humidified container and the

package should not be opened until immediately before sensor cap replacement.

Once the sensor cap has been installed on the ODO sensor as described below,

it is important to keep the sensor in a 100% humid environment. Therefore,

the ODO sensor should be stored either in the grey calibration/storage sleeve

with the sponge moistened or immersed in water, see Sensor Storage for more

information. If the sensor dries out, refer to the Rehydration procedure in this

manual.

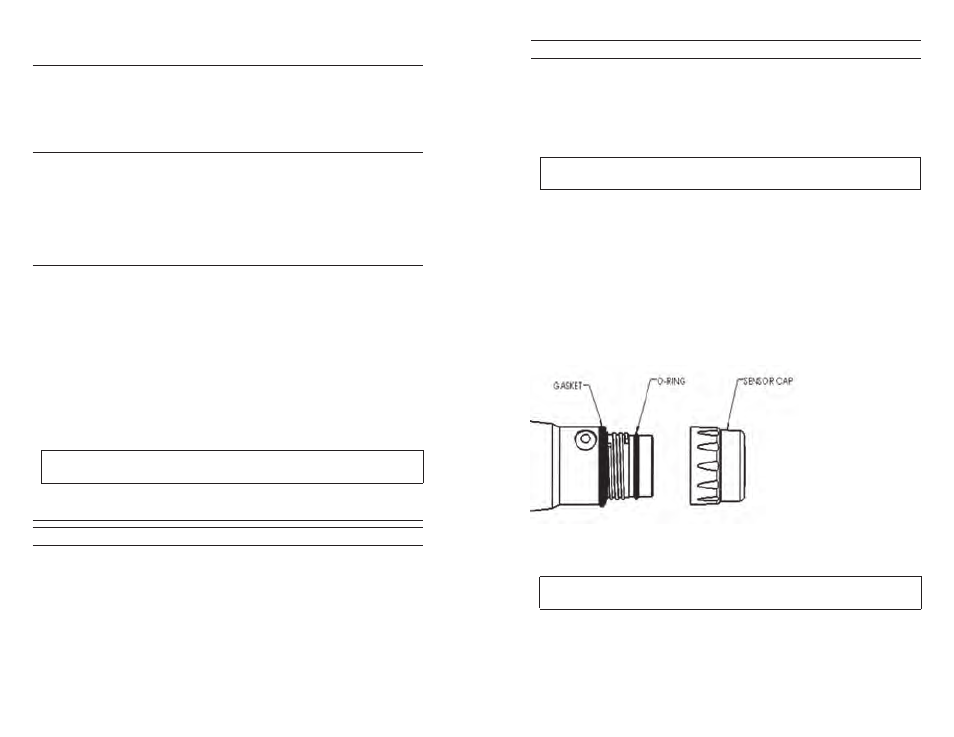

Refer to Figure 8 below when following the instructions for replacing the cap.

Figure 8

Caution: Avoid touching the sensing end of the sensor

cap during the following maintenance procedures.

Remove the old sensor cap assembly from the sensor by grasping the probe

1.

body with one hand and then rotating the sensor cap counterclockwise until

it is completely free. Do not use any tools for this procedure.

u