Calibration - dissolved oxygen – YSI ProODO User Manual

Page 14

18

19

The instrument is programmed to determine the minimum and maximum

data value over the previous 5 samples, and to compute the percent difference

between those values. In this example, that gives a percent change of:

% Change = 100 * ((96.1 – 95.3 ) / 95.3)

% Change = 0.83%

In this example, if the Sensitivity Bar is set to the far right, the Auto Stable

requirement would not be met and AS would continue to blink. However,

if the sensitivity bar is set to the median threshold (1.275%), the Auto Stable

requirement would be met and AS would display steadily on the display.

If the Manual Sampling mode in the System menu is enabled, the Auto Stable

function will automatically be enabled and the sensitivity setting will be used to

determine when to hold the readings on the display. See Sampling Mode in the

System section of this manual for more information on the two Sampling mode

options.

SALINITY CORRECTION

The last feature in the Probe menu is the Salinity correction value for the mg/L

readings. Press Probe

, highlight Salinity, and press enter. Then, use the

numeric entry screen to enter the Salinity value of the water you will be testing

from 0 to 70 ppt.

The value entered here will be used when calculating mg/L from the temperature

and % saturation readings. As the salinity of water increases, its ability to dissolve

oxygen decreases. For example, fully oxygenated 20 °C water at sea level with

zero salinity will hold 9.092 mg/L of dissolved oxygen. If that same sample had

a salinity value of 9 ppt, then it would hold 8.621 mg/L of dissolved oxygen.

Therefore, to obtain accurate mg/L readings, it is important that you know the

salinity of the water you will be testing and input the value into the instrument.

The salinity of fresh water is typically 0-0.5 ppt and seawater is typically 35 ppt.

You will also have the opportunity to enter or modify the Salinity correction

value during DO calibration. Appendix B shows the oxygen solubility table.

calIBratIon - dIssolVed oxyGen

The ProODO sensor is an optical luminescent sensor which has greater stability

and is less susceptible to calibration drift than traditional electrochemistry

sensors. This increased stability means that the instrument may hold its

calibration for many months. However, for the highest data accuracy, YSI

recommends verifying the instrument’s calibration on a daily basis. To verify

the instrument’s calibration, place the sensor in its calibration environment

and check to see that the DO% is reading its calibration value based on the

barometric pressure. Refer to Appendix A for the DO% calibration values based

on barometric pressure.

The ProODO offers several options for calibrating dissolved oxygen. The

first and second methods calibrate the DO % saturation value to either water

saturated air or air saturated water. The third and fourth calibrates in mg/L

or ppm to a solution with a known DO concentration (usually determined by a

Winkler Titration). The fifth option is a zero calibration. If performing a zero

calibration, you must also perform a %, mg/L, or ppm calibration following the

zero calibration. For both ease of use and accuracy, YSI recommends performing

the following DO % water saturated air calibration:

It is not necessary to calibrate in both % and mg/L or ppm.

Calibrating in % will simultaneously calibrate

mg/L and ppm and vice versa.

CALIBRATING DO % IN WATER SATURATED AIR:

1-POINT CALIBRATION

Moisten the sponge in the storage sleeve with a small amount of clean water.

The sponge should be clean since bacterial growth may consume oxygen and

interfere with the calibration. Make sure there are no water droplets on the

sensor cap and temperature sensor and then install the storage sleeve over the

probe. Make sure the DO and temperature sensors are not immersed in water.

The storage sleeve ensures venting to the atmosphere. Wait approximately 5

to 10 minutes for the storage container to become completely saturated and to

allow the temperature and dissolved oxygen sensors to stabilize.

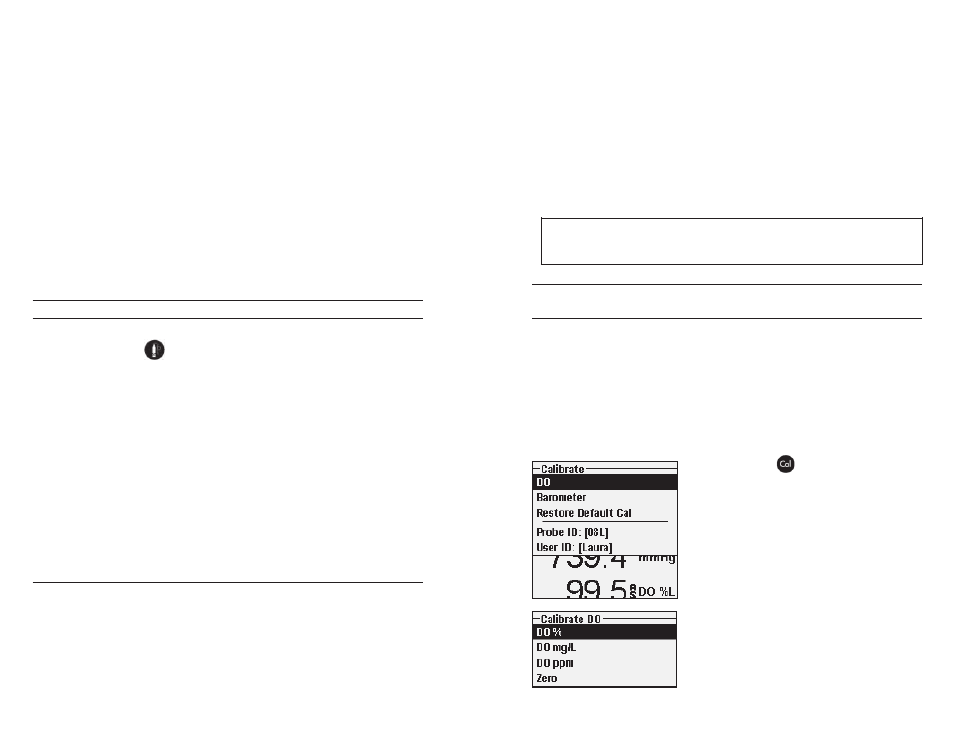

Press Calibration

. If Probe ID or User ID

are enabled in the System GLP menu you will be

able to highlight these features and add, select,

edit, or delete an ID. When enabled these IDs

are stored with each calibration record in the

GLP file.

After selecting the Probe ID and/or User ID if

appropriate, highlight DO and press enter.

Highlight DO % and press enter to confirm.

The instrument will use the value from the

internal barometer during calibration and will

display this value in brackets at the top of the

i